Box Rocket

Well-known member

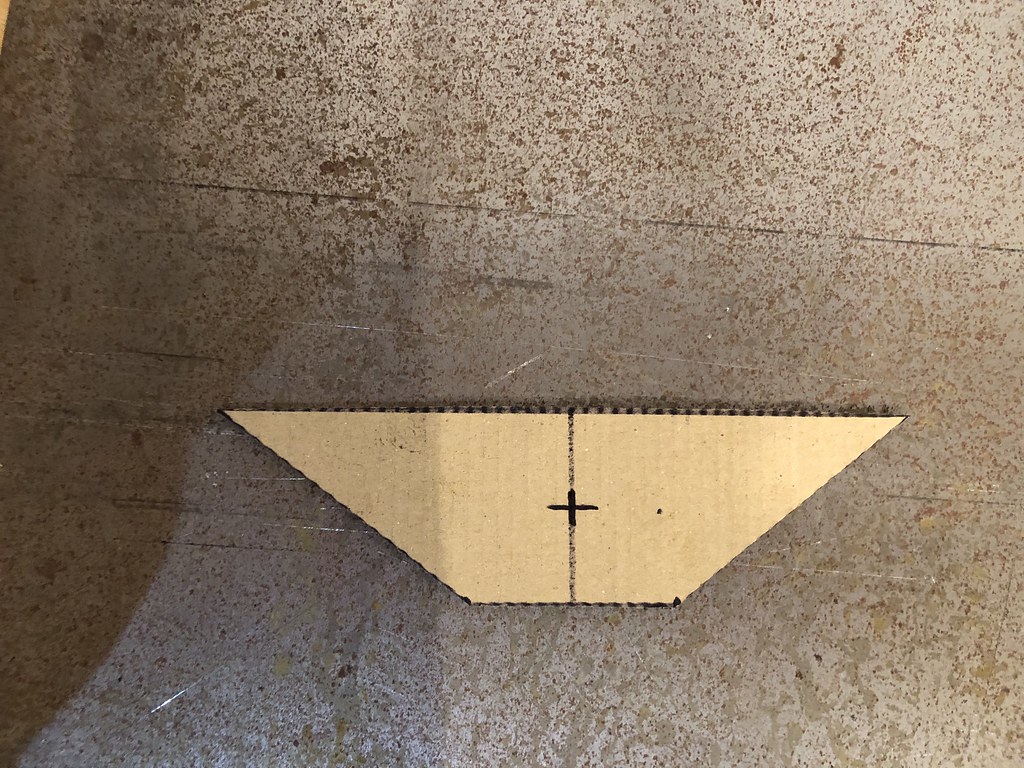

After the bumpstops are sorted, the last step will be to relocate the front axle ~1.5" forward. I plan to do this using the method Darren McRae has been using in Australia for some time now with the Slinky kits and factory radius arms. New plates are welded in to the frame bracket for the radius arms and new holes drilled farther forward. These will give better tire clearance at the firewall. Don't want to move it to far or there are clearance issues with the front panhard.

RadiusArmPlates by Adam Tolman, on Flickr

RadiusArmPlates by Adam Tolman, on Flickr

RadiusArmPlates by Adam Tolman, on Flickr

RadiusArmPlates by Adam Tolman, on Flickr

Axle relocation

Axle relocation Axle relocation

Axle relocation Axle relocation

Axle relocation Axle relocation

Axle relocation Axle relocation

Axle relocation Axle relocation

Axle relocation Axle relocation

Axle relocation Axle relocation

Axle relocation Attic rack

Attic rack Attic rack

Attic rack Attic rack

Attic rack Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Untitled

Untitled Bumper

Bumper Bumper

Bumper Bumper

Bumper Bumper

Bumper Bumper

Bumper Bumper

Bumper Bumper

Bumper Bumper

Bumper Bumper

Bumper Bumper

Bumper