Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Bruce" the 2014 Jeep JKUR Build Thread

- Thread starter KlausVanWinkle

- Start date

KlausVanWinkle

Explorer

I had two issues with mine when I went with JW Speaker (which you can get for around $500 per pair on Amazon right now - great deal). The first was the pair of harnesses that came with mine were crap and one completely failed within about 2 months. They were Headlight Revolution and were apparently accidentally included with my order because I definitely didn't pay for them. I used them because they were free, but as soon as one burned out I bought a set of the Truck Lite harnesses from the local 4wheelparts late on a Saturday which have worked flawlessly.

The second issue I had which is probably the most important thing to change when switching to LED headlights is the aiming them correctly after getting the new ones put in. I don't mean just the factory way of adjusting up and down, but going through the process to remove the blank stud and replacing it with the euro style adjustment screw to aim them side to side. I thought my headlights were just "ok" and one seemed to be brighter than the other, but when I spent the time to dial them in right with the horizontal and vertical adjustment I finally have that "WOW" feeling about their performance. I did a short write up in my build thread in post 16 here http://www.expeditionportal.com/for...Big-O-JKUR-build-thread?highlight=big+speaker and you can find another one out there somewhere if you google the part number. Hopefully making sure the harnesses are good and the headlights are aimed right should make you happy with them.

Thanks for the idea! Yeah I think I need to aim them up. As you can see in the picture, one is just dimmer. I'll check the harnesses if I ever get a second. Since I did it first, I might not have secured the PS anti-flicker module as well as the DS one.

It's the Anti-Flicker module most likely, I've been through a couple of them. Contact Truck-lite and they will get you a new one, their customer service is pretty stellar actually. The last one I received had much better plugs.

That's what I suspected too. We'll see what they say.

I originally had the headlights set as my DRLs. But I figured that the half voltage might mess up the anti-flicker modules. So I switched the DRLs to the foglights for now.

Thanks for the idea! Yeah I think I need to aim them up. As you can see in the picture, one is just dimmer. I'll check the harnesses if I ever get a second. Since I did it first, I might not have secured the PS anti-flicker module as well as the DS one.

That's what I suspected too. We'll see what they say.

I originally had the headlights set as my DRLs. But I figured that the half voltage might mess up the anti-flicker modules. So I switched the DRLs to the foglights for now.

I thought about using my headlights as DRLs, but I too was concerned about the extra strain on the harnesses over a long period of time so I did the same thing and switched it over to fogs as DRLs. I also used some extremely strong zip ties to add another layer of security to ensure the harness stayed connected and weaved it in between the two connectors and pulled them snug which helps keep vibration from rattling them loose over time. It's probably overkill, but it's annoying to pull the grill and headlights just to check the connectors. Maybe you can do that and the horizontal adjusters at the same time when you dig in next. Oh and if you haven't already I'd pull the headlight trim ring and paint it flat black - maybe it's not necessary on the TLs, but on the JWs it looks unfinished without it.

dstock

Explorer

Thanks for the idea! Yeah I think I need to aim them up. As you can see in the picture, one is just dimmer. I'll check the harnesses if I ever get a second. Since I did it first, I might not have secured the PS anti-flicker module as well as the DS one.

For sure make sure it's secured well, the definitely do not like to dangle at all and also make sure it's not up against the PS reservoir hard line as it gets very hot.

dstock

Explorer

For worry free, just cut both connectors and solder for connection. Keep your plug incease you want to return to stock.

Why cut things on an almost brand new vehicle when Trucklite will replace it for free??

KlausVanWinkle

Explorer

yeah i'm not cutting OEM harnesses. I'd use an aftermarket relay harness before I did that. I think it's a defective anti flicker module.

Its not a defective unit. I have been through the same issue on both my lights. you move around the harness and they come back on. I ziptied them together and everything. CUtting a plug off a headlight harness is Not a big deal, if you need to go back just solder it back on. No big deal. I have no issues with mine anymore since that. My anti flicker works fine, no lights cutting out etc.

Comanche Scott

Expedition Leader

Coming from an electrical background, I tend to agree with Kojack. Even if it is the plug on the adapter harness that is defective, eliminating that plug removes a point of failure.

A good solder joint with dual wall adhesive lined Heat Shrink tubing, is a viable upgrade to a replacement harness that may end up with a loose pin, or worse (corrosion) issue down the road.

When I'm looking at building a harness, I look at reducing the number of connectors for this reason.

The OEM style pins, tabs and plastic housings are available aftermarket if you want to go back.

Just something to consider.

A good solder joint with dual wall adhesive lined Heat Shrink tubing, is a viable upgrade to a replacement harness that may end up with a loose pin, or worse (corrosion) issue down the road.

When I'm looking at building a harness, I look at reducing the number of connectors for this reason.

The OEM style pins, tabs and plastic housings are available aftermarket if you want to go back.

Just something to consider.

dstock

Explorer

Its not a defective unit. I have been through the same issue on both my lights. you move around the harness and they come back on. I ziptied them together and everything. CUtting a plug off a headlight harness is Not a big deal, if you need to go back just solder it back on. No big deal. I have no issues with mine anymore since that. My anti flicker works fine, no lights cutting out etc.

Tell that to the dealer when you try to warranty something on the electrical system. Your method is a jury rig at best. The anti-flicker module has been known to fail for reasons other than the connection.

KlausVanWinkle

Explorer

Tell that to the dealer when you try to warranty something on the electrical system. Your method is a jury rig at best. The anti-flicker module has been known to fail for reasons other than the connection.

I suspect the connection is fine. Yeah I'm worried enough that the dual battery system would totally void the electrical system warranty. The terrible dealer I went to on Tuesday started to try to use the spacer lift and airlift airbag springs as an excuse for why the couldn't find the source of a grinding sound. I think they'll use any excuse they can get their hands on.

dstock

Explorer

I suspect the connection is fine. Yeah I'm worried enough that the dual battery system would totally void the electrical system warranty. The terrible dealer I went to on Tuesday started to try to use the spacer lift and airlift airbag springs as an excuse for why the couldn't find the source of a grinding sound. I think they'll use any excuse they can get their hands on.

This +1000!

I had an electrical issue that I wanted the dealer to check out, turned out to be nothing, but showing my Service Advisor that all the accessories on my JK were hooked to the Aux battery, was enough for him. I told him it was done that way intentionally to avoid any issues and he said I was smart to do it that way to avoid any issues with Chrysler.

Curious which dealer you went to? You can PM if you don't want to air it here.

Comanche Scott

Expedition Leader

Tell that to the dealer when you try to warranty something on the electrical system. Your method is a jury rig at best. The anti-flicker module has been known to fail for reasons other than the connection.

Good points dstock. :beer:

You have a very valid point with the warranty issue, and that it is not always a loose connection.

Wiggling the connector would tell if it's a connection issue.

In your scenario you would simply unplug the harness and put the stock lights back in then go to the dealer.

In Kojack and my scenario we would need to buy the tabs cut the leads (again), crimp on the pins and install in the original connectors. Then we'd need to hope the dealer tech isn't savvy enough to realize the harness is slightly shorter than original.

.

I'm pretty competent in this area and have all the tools. "If" was going to change from stock lighting the H13 connectors would be removed, because it's just too easy for me not to do this. However, if I didn't have the tools and experience, I may look at this a bit differently.

dstock

Explorer

Good points dstock. :beer:

You have a very valid point with the warranty issue, and that it is not always a loose connection.

Wiggling the connector would tell if it's a connection issue.

In your scenario you would simply unplug the harness and put the stock lights back in then go to the dealer.

In Kojack and my scenario we would need to buy the tabs cut the leads (again), crimp on the pins and install in the original connectors. Then we'd need to hope the dealer tech isn't savvy enough to realize the harness is slightly shorter than original.

.

I'm pretty competent in this area and have all the tools. "If" was going to change from stock lighting the H13 connectors would be removed, because it's just too easy for me not to do this. However, if I didn't have the tools and experience, I may look at this a bit differently.

Thanks.

I could have done the same as well but just don't want the hassle from the dealer, and I have the Lifetime warranty on my JK. Plus, I paid Trucklite for a product, I want the damn thing to work!!

:beer: back at ya!

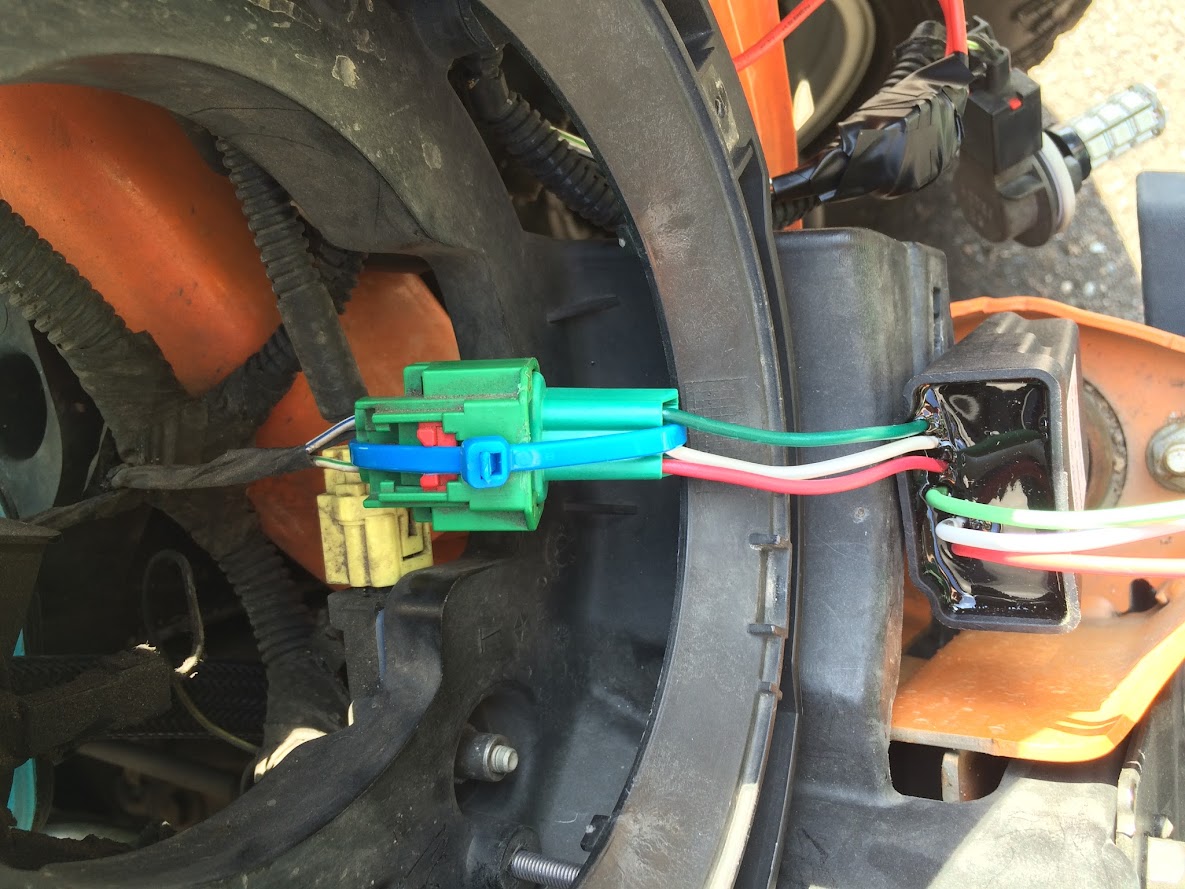

I too was afraid of any warranty issues, so that's why I used dielectric grease, strong zip ties and electrical tape to secure everything. It is as stable as it can get without ditching connectors and soldering which I did not feel comfortable doing, and it didn't seem like there was enough slack/excess wire there in case something went wrong either. Here are two pics of how I made secured the harness:

Similar threads

- Replies

- 0

- Views

- 738

- Replies

- 14

- Views

- 3K

- Replies

- 8

- Views

- 2K

- Replies

- 1

- Views

- 1K