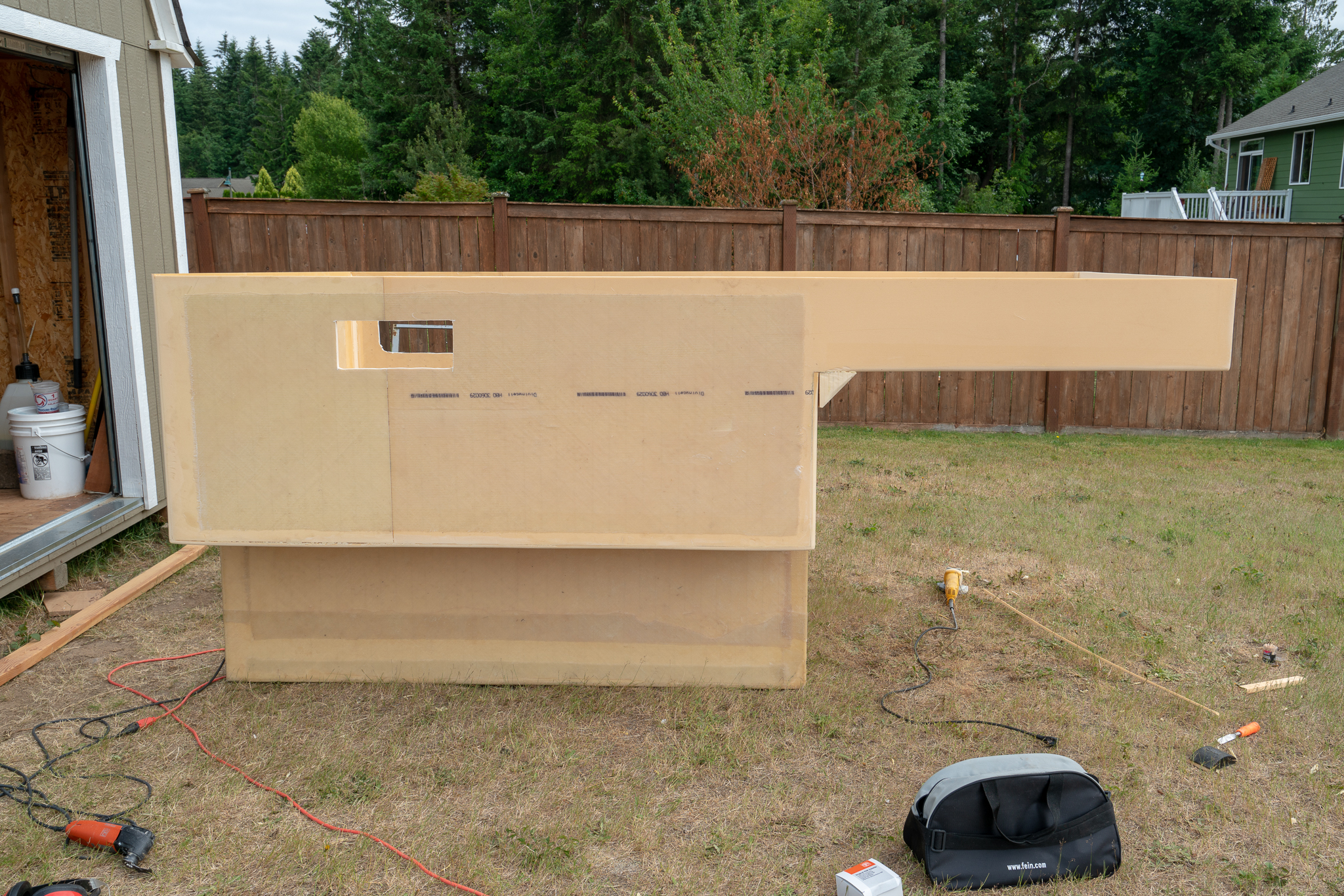

We decided to start with the largest piece first, which is the forward vertical edge of the shell, over the beam, and the underside of the cabover. We started with the vertical edge because it's so hard to get the resin not only on the fiberglass, but to get it to soak in. We did manage it, but vastly underestimated how rough the beam still was from the sanding. Apparently all I had managed to do was smooth over the giant lumps and I somehow failed to notice this. So now we have a huge sheet of fiberglass dripping with resin that we're trying to roll out and every time we pull one direction, it pulls off the foam in another spot. To make matters worse I guess we just picked the absolute perfect conditions for the resin to set up because in less than 5 minutes, our bucket of mixed resin, the huge clumps on the glass, and anything on the camper that we're trying to work are all hard. Complete freaking mess of a disaster... Bubbles and resin everywhere. Nothing to be done about it now except let it set up and deal with it later.

After we spent enough time glaring at our mess, it was time to start cutting out the spots that were bubbled, or had too much resin.

After we cut the sides, the glass just peeled off the foam gently with a chisel. Awesome...

This is all we have to fix...

After about 2-3 in the afternoon it gets way too hot to be out by the shed working, so we made some taco salads and took a break.

Yes those are Doritos...

After dinner, we moved the camper over to the house in the shade to keep cleaning up the damaged beam and sand everything down to where it should have been to start with.

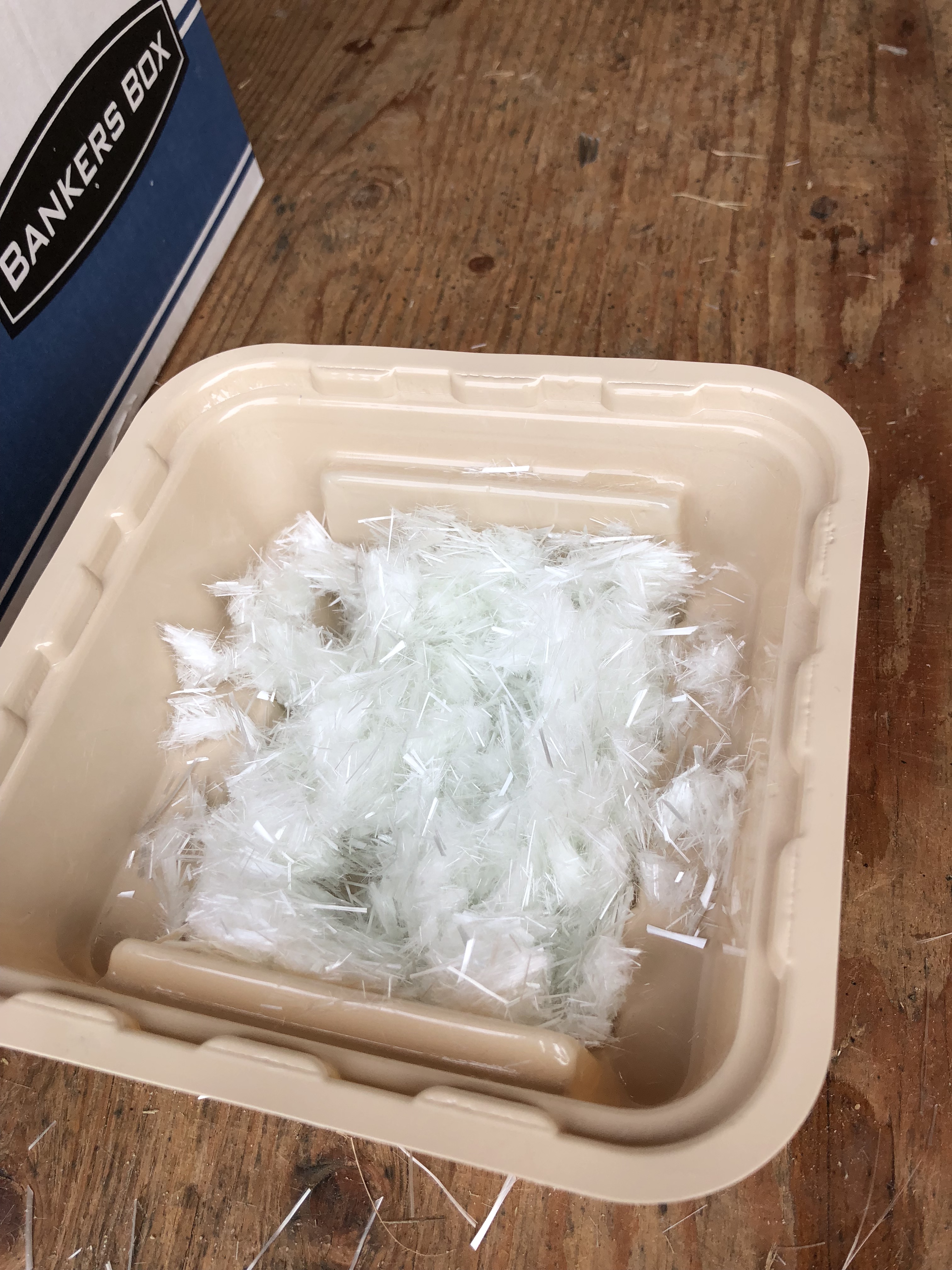

The sanding took the rest of the evening, but on a fun side note, I ordered two small waterproof hatches so I can access the tie down points inside the truck cab. Those came in today!