I got the metal bits sanded before the sun started beating on it and making the aluminum too hot to work with! With that out of the way, I needed to start gluing in the structure that would hold the false floor where the water tank would go.

More paving stones and the truck bed cargo divider... couldn't have done it without them!

I bought a few rolls of the 3" 6oz glass cloth. It's so easy to work with and just cut off various lengths of it. My plan for the structure was to glue the wood where it needed to go and then take the cloth and just fiberglass everything in place. I made sure to cut a few layers and stage everything because once you start rolling, you have to just keep going until it's all gone. This stuff doesn't leave a lot of time to mess around!

One side finished. Not that you can tell because it's clear!

Everything in the picture is now permanent!

The side pieces under the seats that make up part of the floor could have to hold some weight, so I added a layer of fiberglass to them just in case.

Now those get glued in!

Now the seats need to be glued in!

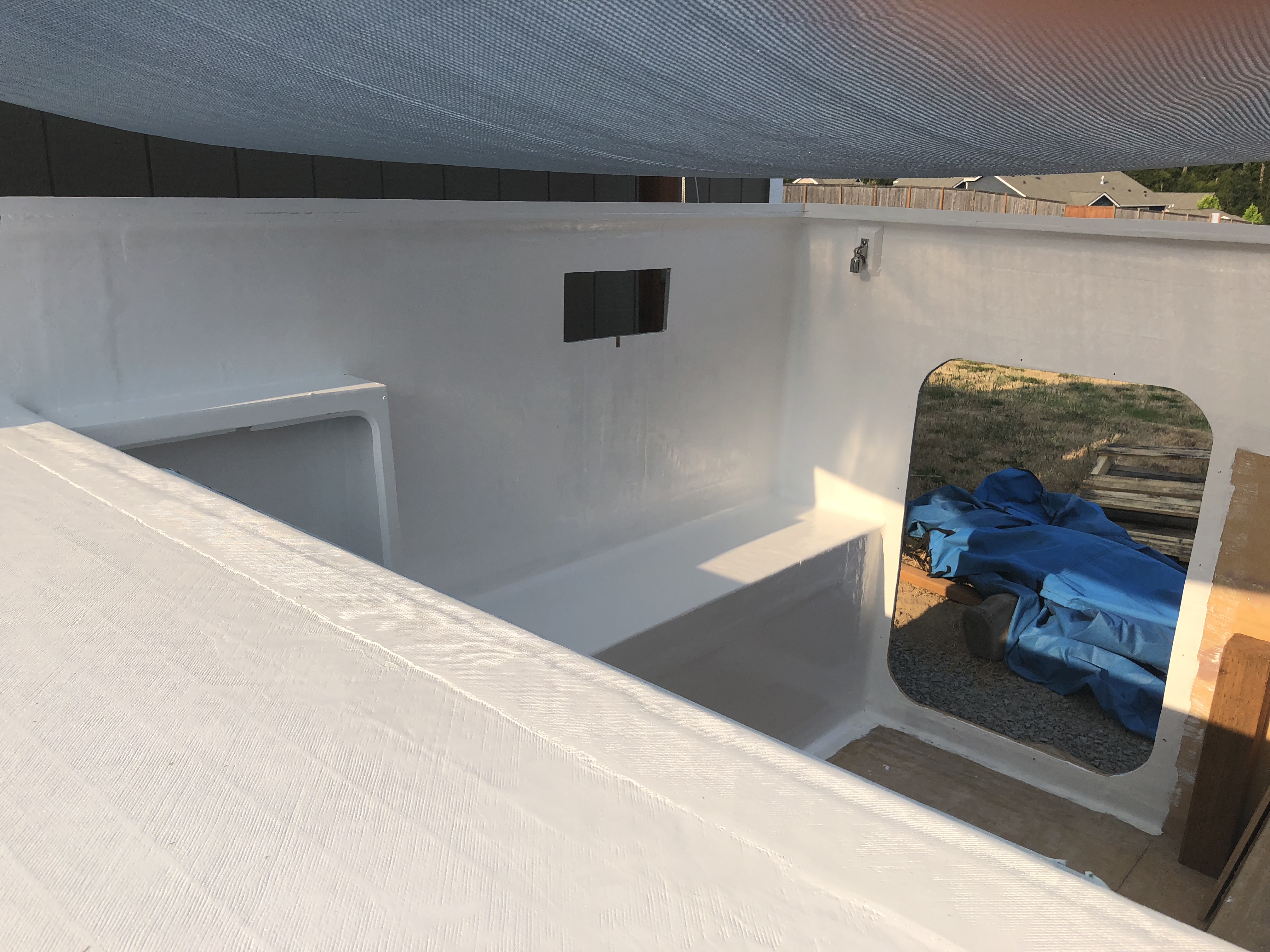

This is inside the tank area. I rounded the edge of the board so the glass would lay over it more easily and so the sharp edge wouldn't cut the material of the "water bladder" we chose to use.

Waiting for things to dry takes up so much time...

Time for some more fiberglass!

I was using small 4" foam rollers and disposable trays for this part. Apparently the heat outside and the hot sun overhead was too much for the epoxy and it began to set up way sooner than it had been. The foam rollers would start to smoke and get so hot I was unable to touch them. This happened 3 times (yeah, I don't learn...) and then I decided I should probably take a break and let it cool down a little bit otherwise I was just going to keep toasting rollers and wasting material.