IdaSHO

IDACAMPER

Your setup is pretty much identical to what Im running.

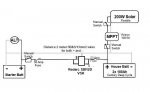

200Watts of solar, MPPT, 200AH of battery, and the ability to charge via alternator when running.

Though Im equipped for a full 200A of charging from th alt if available and if the batteries want it.

Wiring is sized for 200A, fused for 200A and uses a 200A continuous duty relay.

Huge side benefit for this setup is the ability to not only share available cranking amps from house bank to starter, but to also charge the truck batteries via solar! :ylsmoke:

Experience has shown me this...

* I charge my house bank via the alternator whenever we are mobile, even with available solar.

Doesnt seem to bother anything.

*Earth for camper should also be earth for chassis. If not, make sure you have good grounds straps to make it so.

My camper is not steel, so each and every device has a ground conductor that traces back to the fuse panel.

*Up to you. In order to maintain the house bank deep cycles, you need a power source of some sort.

Solar works great for this with a good charge controller. Otherwise, disconnect the solar and place the batteries on a trickle charger/maintainer.

Regardless, make sure you have the ability to isolate components related to the solar panels. Afterall, they done have an OFF switch!

I did this with inline breakers as seen below

using two of them, Im able to isolate the charge controller from the solar and/or the house bank, just in case.

200Watts of solar, MPPT, 200AH of battery, and the ability to charge via alternator when running.

Though Im equipped for a full 200A of charging from th alt if available and if the batteries want it.

Wiring is sized for 200A, fused for 200A and uses a 200A continuous duty relay.

Huge side benefit for this setup is the ability to not only share available cranking amps from house bank to starter, but to also charge the truck batteries via solar! :ylsmoke:

Experience has shown me this...

* I charge my house bank via the alternator whenever we are mobile, even with available solar.

Doesnt seem to bother anything.

*Earth for camper should also be earth for chassis. If not, make sure you have good grounds straps to make it so.

My camper is not steel, so each and every device has a ground conductor that traces back to the fuse panel.

*Up to you. In order to maintain the house bank deep cycles, you need a power source of some sort.

Solar works great for this with a good charge controller. Otherwise, disconnect the solar and place the batteries on a trickle charger/maintainer.

Regardless, make sure you have the ability to isolate components related to the solar panels. Afterall, they done have an OFF switch!

I did this with inline breakers as seen below

using two of them, Im able to isolate the charge controller from the solar and/or the house bank, just in case.