A few years ago I made a pop-top camper lid for my Jeep-tub trailer.

In total I think I spent about $300 on the lid, hardware and canvas.

The pop-top is roughly the size of a JKU roof, and the same basic design can be used to convert a JKU hardtop to a pop-top camper.

A good plan would be to convert a hardtop to modular and then build the pop-top lid to fit on it, perhaps using the roof from a second hardtop so the camper top could be swapped for an ordinary roof when the Jeep wasn't in use as a camper. Everything I'm about to describe would work fine on a stock hardtop (not converted to modular), but a modular top would be much easier to handle once the pop-top was installed because it can be installed/removed in pieces instead of a single huge, heavy full hardtop.

I've omitted many details of construction in this post, I'll just cover the main modifications.

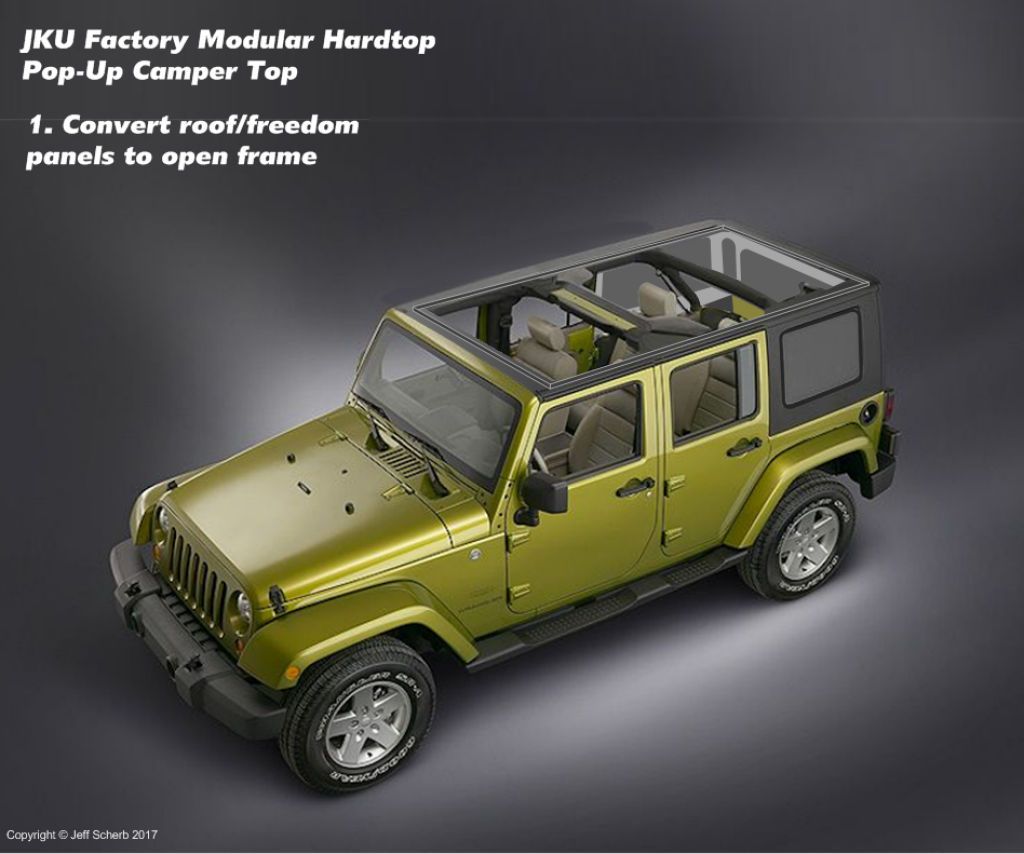

The first step is to turn the roof and freedom panels into a "ring" around the 4 sides. Removing the center of the roof reduces the overall height of the camper because the sleeping platform can rest on top of the roll bars. It would be possible to do this so that the roof/freedom panels remain intact, but the resulting camper would be higher when closed. I'd probably bond all the parts together into a solid ring rather than leaving the remains of the freedom panels as separate parts, but either way could work. Ideally there would be some framing around the opening, which would work best if everything were bonded together and not separate parts.

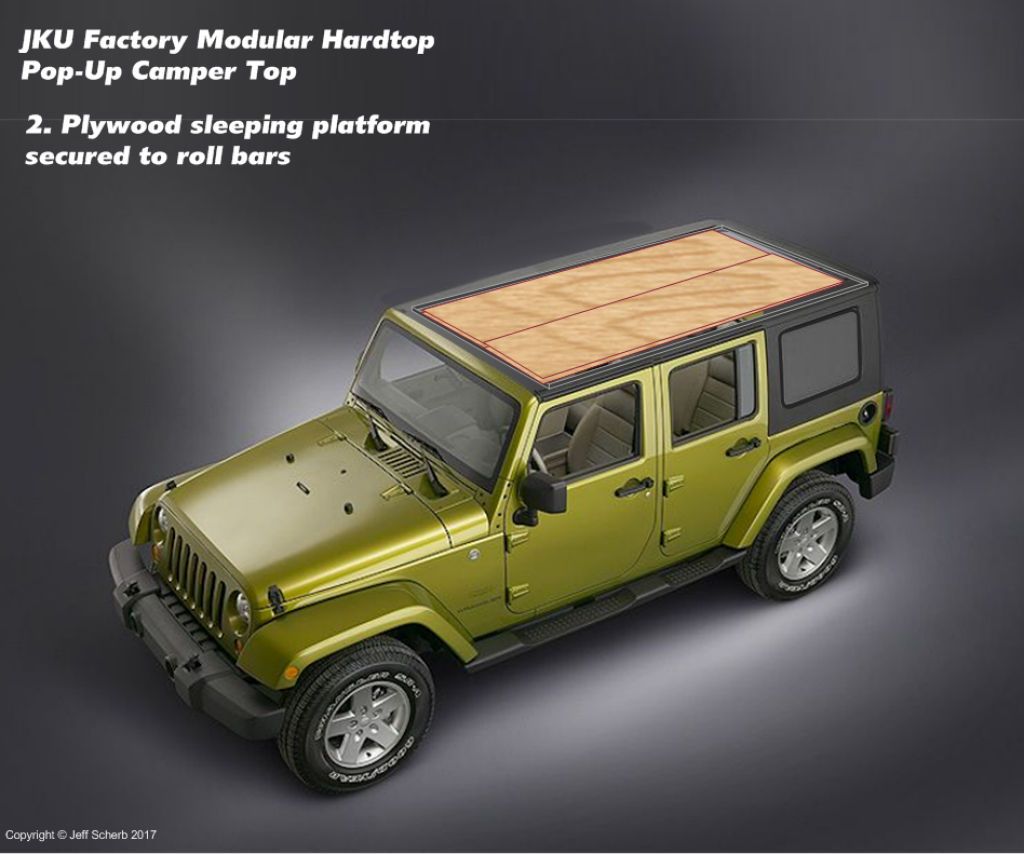

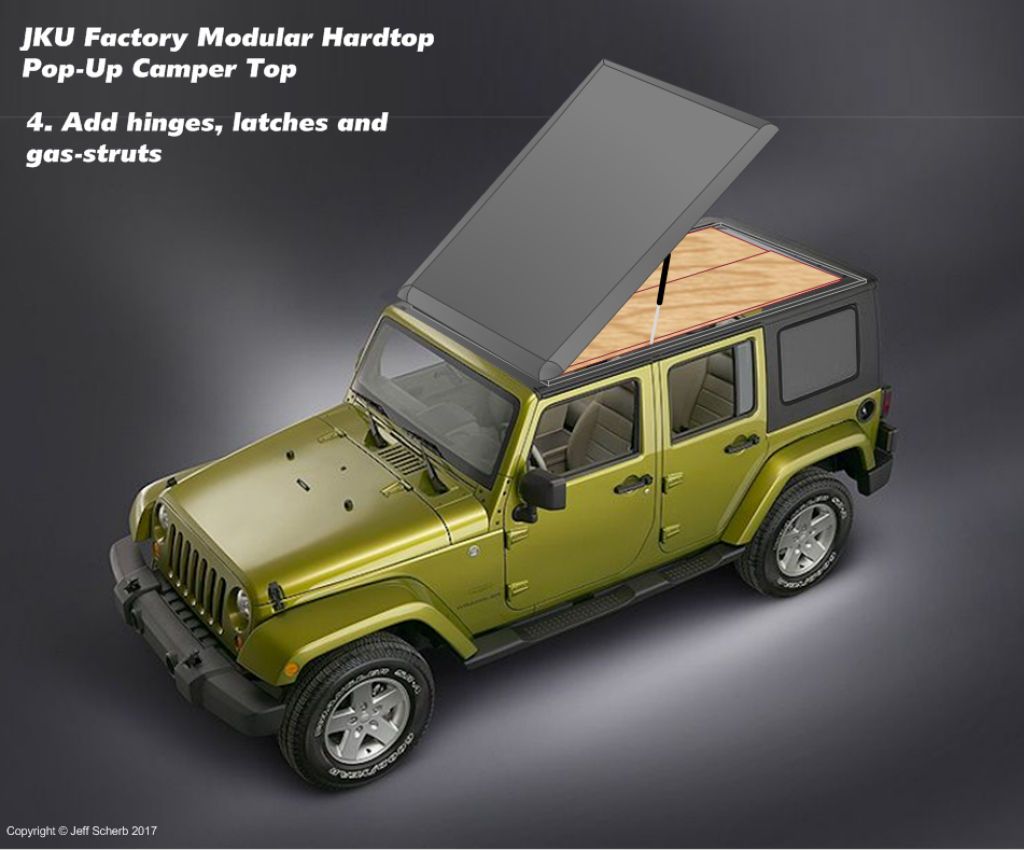

A sleeping platform made from plywood is secured to the roll bars. Wooden cross-ribs would support the plywood where it's not supported well enough by the roll bars.

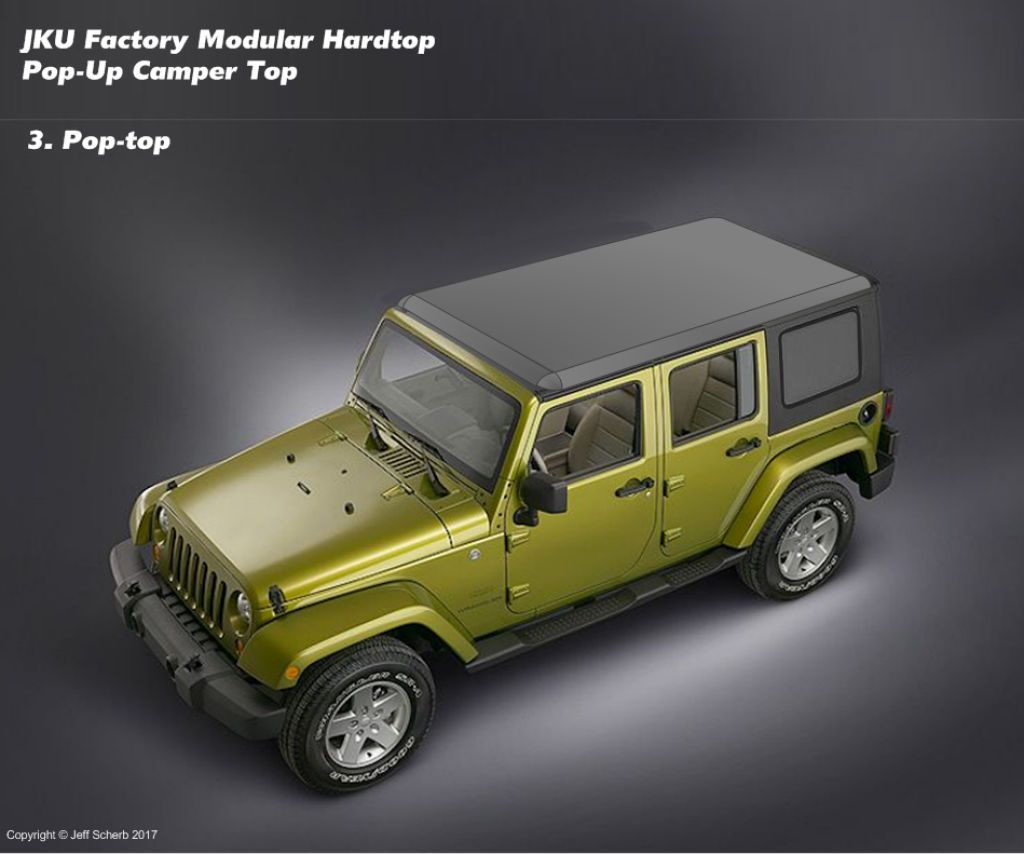

Next a lid is constructed. The lid should be high enough to enclose all of the bedding and whatever else you would want to keep up there. Perhaps it would be 4" high off the roof.

When I made the pop-top lid for the trailer, I used a combination of TrailTop fiberglass framing components (the whiter parts in the photo below) and 1/4" plywood (I used pre-primed plywood that was an off-white color), with a few other wood parts for strength. The TrailTop parts provided nice rounded corners and curved sides, but not having TrailTop parts, you could build the entire shell from wood.

I finished the cover in Olympic "Rescue It", which is an acrylic coating for home decks. Applied with a roller, it provides a nice textured finish that's very durable, hides the wood grain and the joints between the TrailTop fiberglass parts and the wood, and is reasonably priced. The same could be done with the hardtop camper lid. Many colors are available.

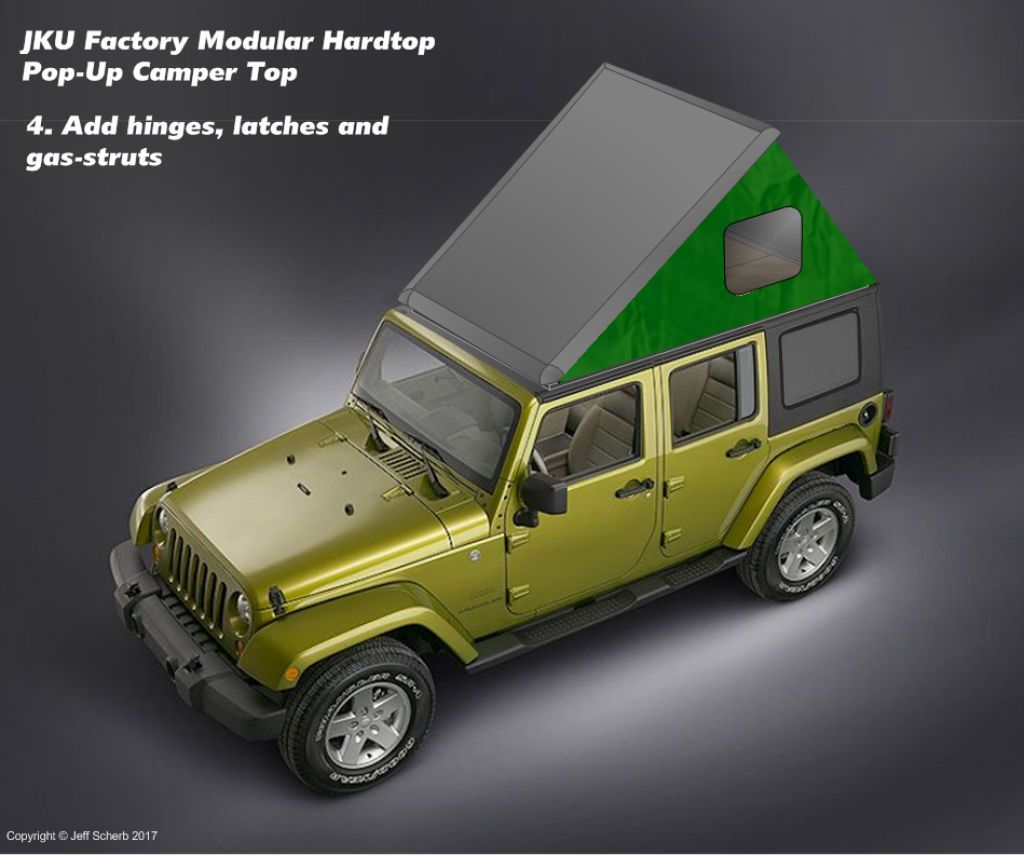

The lid gets hinges, latches and gas struts. And weatherstripping, but I've omitted that detail from this post.

Once the mechanical assembly is done, side panels are sewn from an appropriate waterproof fabric. Windows/screens are added to your preference, and probably a rear door as on the trailer. A ladder would be used to enter from the back, or you could put a hatch inside in the sleeping platform for entry from the inside. I can show more photos of the trailer pop-up if anyone's interested in the details of the side panels, windows, zippers, etc.

As I said, I've omitted a bunch of details, but the above should give you an idea of what's required. This shows a very basic pop-top, lots of things could be done to enhance it - scissor-type hinges to raise the front, for example, or a more elaborate canvas design, solar panels, etc...

Given that I only spent about $300 on my trailer pop-top, I believe you could build a complete basic pop-top hardtop camper for a JKU for less than $750. That cost includes the cost of the materials for the modular conversion of the hardtop, the cost of building the lid and the hardware for it, all the material for sewing the sides, but not the cost of the hardtop itself.