You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

COSTMAN13's 2001 Tacoma

- Thread starter Costman13

- Start date

Louisd75

Adventurer

On another note. I am in the market for a 110V Welder and have my sights on a Hobart Handler 140, up to 1/4" and 140 amps. I realize that in the welder world the bigger the better. I have a Lincoln Weld Pak HD 220V MIG in my Father's shop, but with no 220 access in my current house, its going to stay put for the time being.

Can anyone offer insight on 110V welders such as the Hobart Handler 140?

Truck is looking good. We'll have to try and get together sometime to get the tires dirty now that I'm on dry land once I'm off the cellphone leash (Wife is due soon). My recommendation on the welder is to look at the 120/220 models. I've got a Miller 211 that I can run off of a 120 wall outlet or the 220 electric dryer outlet just by changing the plug on the end. It looks like Hobart has a similar version in their Handler 210 model. Lincoln also has the Power Mig 180 that does both. All of these are likely more expensive than a small 120 wire feed, but you won't be wanting a different machine down the road if you move somewhere that has 220. If you're in town today, the Bellingham Technical College is having a welding rodeo going on where you can go and check out machines from different manufacturers and talk with the reps. Not sure who all is going to be there, but if you've got some free time it may be worth checking out: http://www.weldingrodeo.com/

Something else to keep in mind is that if you've got a laundry room in your place you've probably got a 220 outlet. The last house I lived in had an outlet in the laundry room, which was in a bathroom, which was in the middle of the house. I picked up a 50' 220v extension cord and was able to run it out into the garage. It was a big PITA to get to the outlet, but it was worth it since otherwise I could only weld a few inches at a time before tripping the 120 breaker and have to stop to let things cool down.

Costman13

Adventurer

Thank you for the compliments guys! I am very pleased with the bumper.

Louis, Congrats on the child! Thanks for the insight on the 120/220 units, though more expensive, it would be awesome to be able to plug and play anywhere. My reasoning for not looking harder into a 220 or a 120/220 (though that seems like an excellent choice) is because I have a 220 unit collecting dust in my Dad's shop for the time being, or until I find a place with a nice garage. In the house I live in now the garage is separated and my landlord uses it for storage, meaning I have no access. The warehouse at work, surprisingly enough also is without a 220v outlet. I do not want to rush this decision as welders aren't the cheapest tool in the shop, and I think it will pay off to figure out my needs and get into the right one. Or make a trip to central OR and get the Lincoln back from my old man... While in high school I talked my parents into letting me run an extension cord through the house from the laundry room to the garage! Great minds think alike...

Louis, Congrats on the child! Thanks for the insight on the 120/220 units, though more expensive, it would be awesome to be able to plug and play anywhere. My reasoning for not looking harder into a 220 or a 120/220 (though that seems like an excellent choice) is because I have a 220 unit collecting dust in my Dad's shop for the time being, or until I find a place with a nice garage. In the house I live in now the garage is separated and my landlord uses it for storage, meaning I have no access. The warehouse at work, surprisingly enough also is without a 220v outlet. I do not want to rush this decision as welders aren't the cheapest tool in the shop, and I think it will pay off to figure out my needs and get into the right one. Or make a trip to central OR and get the Lincoln back from my old man... While in high school I talked my parents into letting me run an extension cord through the house from the laundry room to the garage! Great minds think alike...

Costman13

Adventurer

Costman13

Adventurer

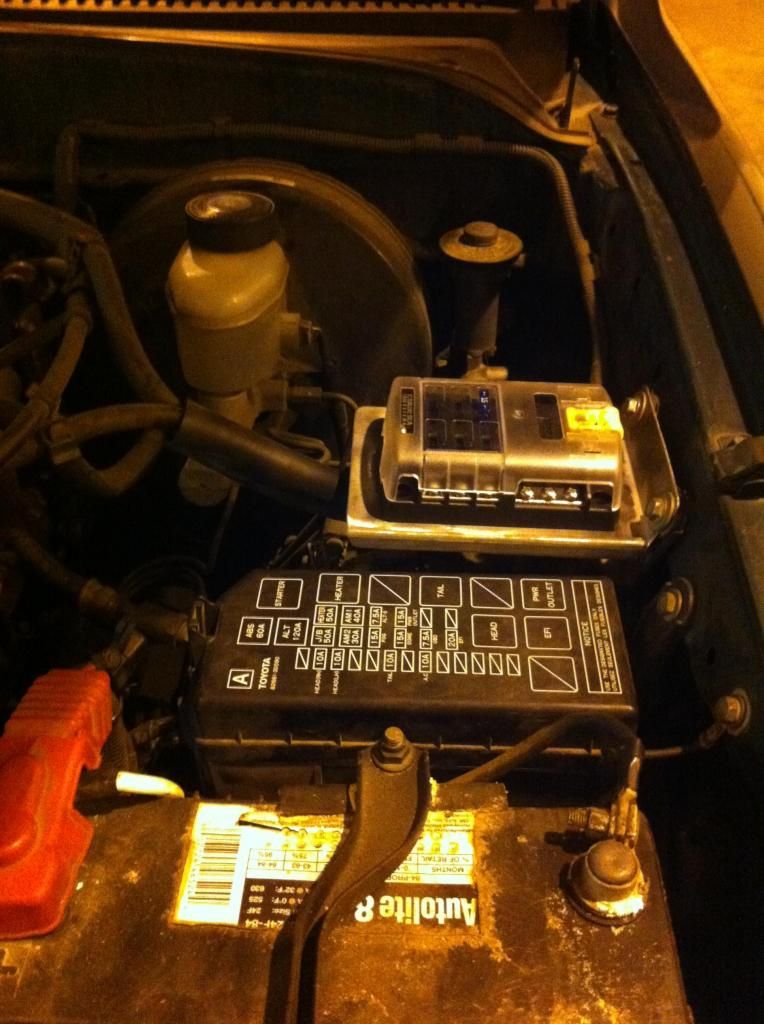

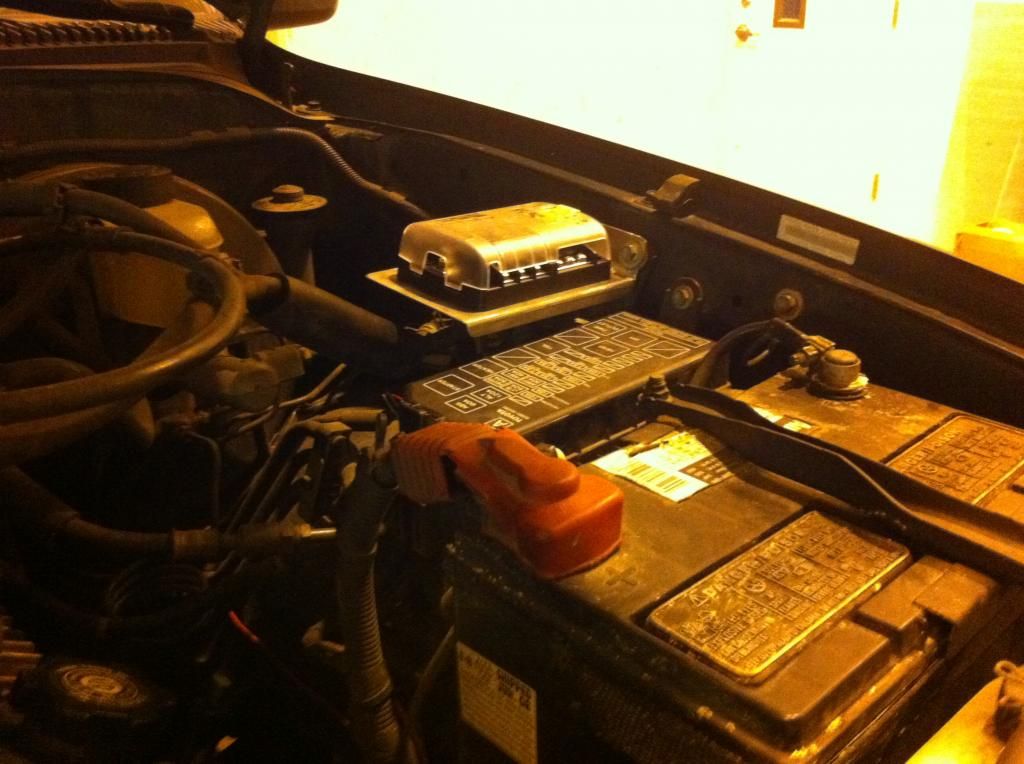

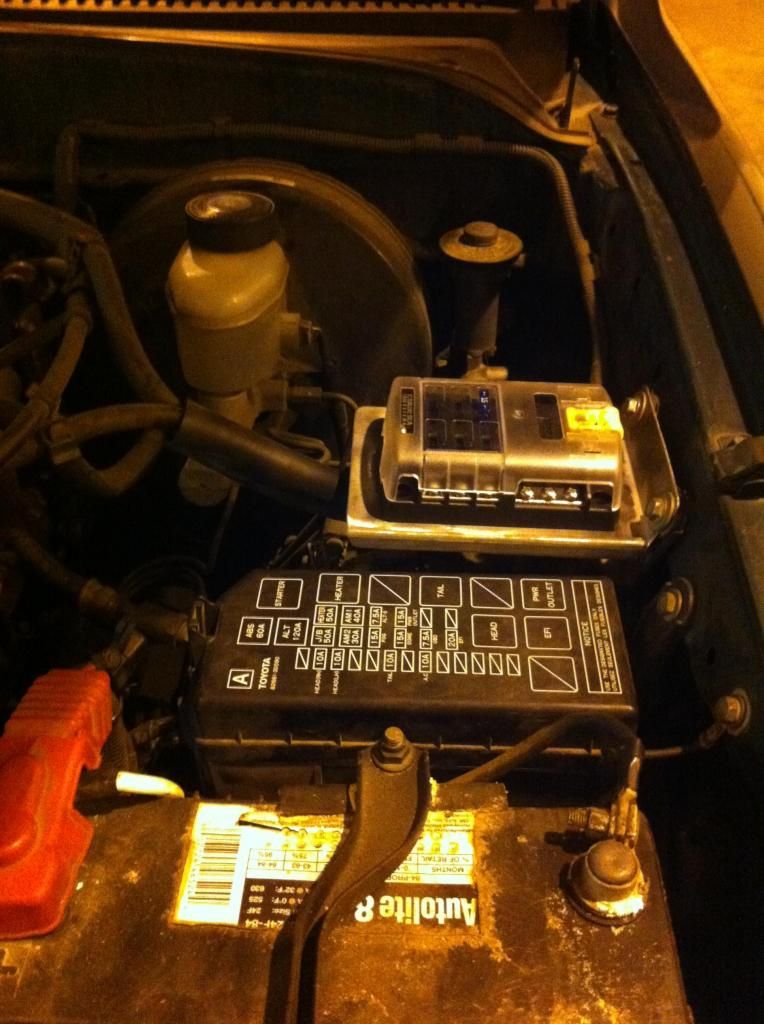

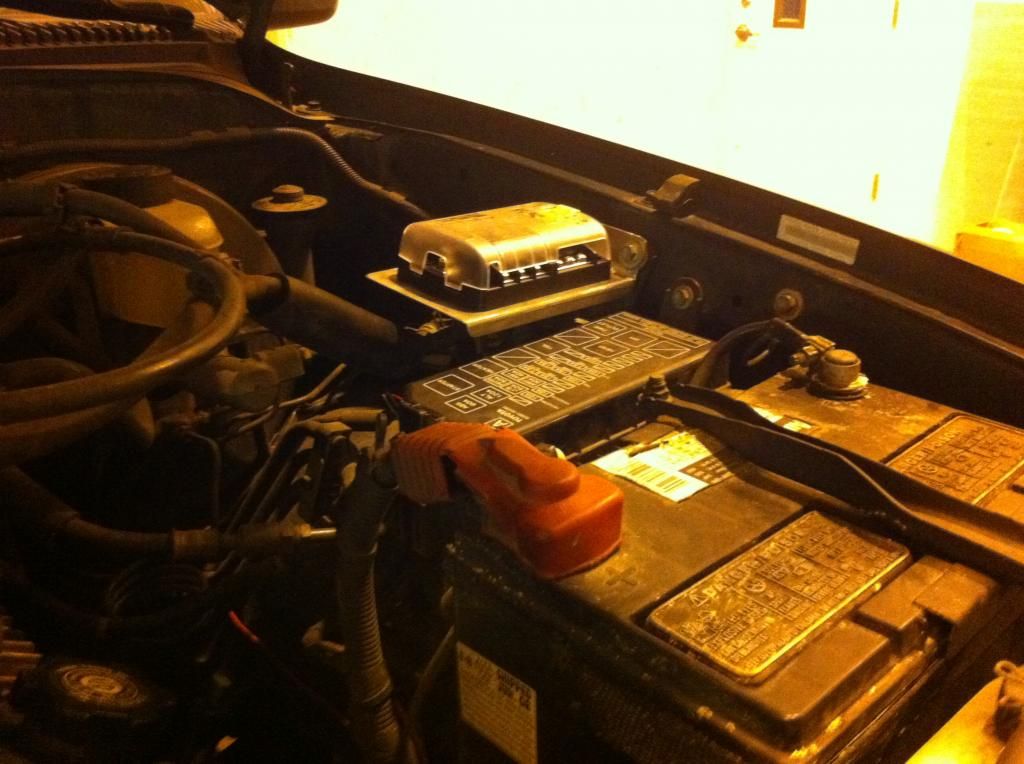

Getting ready to square away my wiring. I have no clue what I am doing when it comes to electrical, so please say some something if you see something amiss.

Being that the Hella 4000s did not fit on the APEX bumper and I failed to fit everything prior to powder coat, I went ahead and cut the grill just enough to use the full range of adjustment on the lights. Good news is, you can't really tell the grill has been cut... unless you look.

Being that the Hella 4000s did not fit on the APEX bumper and I failed to fit everything prior to powder coat, I went ahead and cut the grill just enough to use the full range of adjustment on the lights. Good news is, you can't really tell the grill has been cut... unless you look.

MGTexas

New member

I have a 140 Handler. Bought it specifically to do projects on my 2001 DC a year ago because my Miller Bobcat is a bit difficult to use on fine work. I have been very pleased with it in all areas. The heat and speed are very consistent. Came with gas shielding set up. Actually welds thicker clean steel than I thought it would. I did one project that involved 5 foot long beads on a rear bumper and yes that was too much for it without cooling a bit. Otherwise it is great. You will not be disappointed if you go with it. I use 10lb rolls of .35 fluxcore.

Mike

Mike

Attachments

jeverich

Luddite

Looks great!

Just got word that my High Clearance rear/tire carrier is finished up; perfect timing to go back to the Bering Sea..

It'd definitely be worth your time to use high quality Ancor Heat Shrink crimp ring terminals going into your Blue Seas panel. LFS has 'em.. but be warned they aren't cheap.

Shrink wrap and wire loom are your friends.

I'm going to be heading up to my house on Saturday, probably be up some time in the evening. Dunno if you'd be up for grabbing a beer or something.

Just got word that my High Clearance rear/tire carrier is finished up; perfect timing to go back to the Bering Sea..

It'd definitely be worth your time to use high quality Ancor Heat Shrink crimp ring terminals going into your Blue Seas panel. LFS has 'em.. but be warned they aren't cheap.

Shrink wrap and wire loom are your friends.

I'm going to be heading up to my house on Saturday, probably be up some time in the evening. Dunno if you'd be up for grabbing a beer or something.

Costman13

Adventurer

Had a great weekend.

Jake (jeverich) and Louis (Louisd75) stopped by work Saturday evening for a little meet and greet / route planning. We decided to go check out FS 17 off the S. Skagit Hwy (same route as the 2012 Christmas Tree Run) and see if it was passible just yet. I had never been up that side of the Skagit Valley, but have always been curious. We hit snow just above 3200', if I remember correctly, and were able to make it relatively far considering the depth of some of the drifts. I received a great lesson on self recovery (multiple times) and was really able to figure out which recovery gear is most important and which will work best for my needs. Both Louis and Jake have very capable and well thought out rigs. It was a great experience to tag along with these more experienced drivers. I will let the pictures do the talking.

At the trailhead. (FS 17)

Louis in the snow!

Recovery #1, shovels...

Louis' truck is the perfect example of simplicity and functionality. Very well thought out and capable rig.

One of Louis' Soft Shackles. These things are incredible.

Recovery number 5 or 6? Winch.

Skagit Valley below.

Airing up back at the S. Skagit Hwy

Great day. Thanks for looking.

Jake (jeverich) and Louis (Louisd75) stopped by work Saturday evening for a little meet and greet / route planning. We decided to go check out FS 17 off the S. Skagit Hwy (same route as the 2012 Christmas Tree Run) and see if it was passible just yet. I had never been up that side of the Skagit Valley, but have always been curious. We hit snow just above 3200', if I remember correctly, and were able to make it relatively far considering the depth of some of the drifts. I received a great lesson on self recovery (multiple times) and was really able to figure out which recovery gear is most important and which will work best for my needs. Both Louis and Jake have very capable and well thought out rigs. It was a great experience to tag along with these more experienced drivers. I will let the pictures do the talking.

At the trailhead. (FS 17)

Louis in the snow!

Recovery #1, shovels...

Louis' truck is the perfect example of simplicity and functionality. Very well thought out and capable rig.

One of Louis' Soft Shackles. These things are incredible.

Recovery number 5 or 6? Winch.

Skagit Valley below.

Airing up back at the S. Skagit Hwy

Great day. Thanks for looking.

Louisd75

Adventurer

Excellent pictures and writeup...

Did I say excellent pictures?

Let me know if you'd still like a key for my garage, I'm sure I could work something out with the landlord.

I'm thinking your truck might be a little bit heavier when I get back from the Bering Sea...:sombrero:

Great pictures and great time. I was exhausted by the time I got home after slogging back and forth in the snow for so long. I was all set for a nice day of sleeping in the morning after and then my wife's water broke. Sleep is overrated anyways. She did admire the pics between contractions (We're in a lull at the moment, hopefully I can get some shut eye before we have to get in the car for the 2nd time). Looks like that might be my last trip for a little while.

Costman13

Adventurer

Thanks Jake! I'll let you know. If I can get away to grab my welder and a few other shop tools, I may take you up on that!

WOW! Talk about close timing Louis :Wow1:! So any day now??

On another note, while talking with my landlord about this last weekends activities and my new found respect for a winch, He told me he had one sitting around in his garage and it was mine if I wanted it. SCORE. I cruised by to check it out and it was an old Warn MX8000. Pretty dirty and beat up. Of coarse I took it home with me stripped it of its old and abused wire rope, and opened up the gearbox and motor to check things out. The gears appear to be in great shape as does the entire gearbox. The motor has some moderate dust in it but looks like some electrical contact cleaner and a rag could clean it up really nice. There is NO CORROSION OR RUST anywhere to be found inside! I plan on replacing all electrical cables, re greasing the gearbox with a good synthetic based extreme pressure grease, seal up the motor and gearbox with RTV and giving the exterior a new coat of paint.

As far as parts availability, it looks like many MX series parts are now "unavailable". Although I was able to order a few gaskets and ew "tie rods" as the old ones are slightly bent and rusty.

Does anyone here have some experience with the older warn MX8000's, the predecessor to the now M8000?

WOW! Talk about close timing Louis :Wow1:! So any day now??

On another note, while talking with my landlord about this last weekends activities and my new found respect for a winch, He told me he had one sitting around in his garage and it was mine if I wanted it. SCORE. I cruised by to check it out and it was an old Warn MX8000. Pretty dirty and beat up. Of coarse I took it home with me stripped it of its old and abused wire rope, and opened up the gearbox and motor to check things out. The gears appear to be in great shape as does the entire gearbox. The motor has some moderate dust in it but looks like some electrical contact cleaner and a rag could clean it up really nice. There is NO CORROSION OR RUST anywhere to be found inside! I plan on replacing all electrical cables, re greasing the gearbox with a good synthetic based extreme pressure grease, seal up the motor and gearbox with RTV and giving the exterior a new coat of paint.

As far as parts availability, it looks like many MX series parts are now "unavailable". Although I was able to order a few gaskets and ew "tie rods" as the old ones are slightly bent and rusty.

Does anyone here have some experience with the older warn MX8000's, the predecessor to the now M8000?

Louisd75

Adventurer

Thanks Jake! I'll let you know. If I can get away to grab my welder and a few other shop tools, I may take you up on that!

WOW! Talk about close timing Louis :Wow1:! So any day now??

Tuesday at noon Amelia came into the world

Sweet score on the winch! Before you install it, take a good look at the drum. You've mentioned wanting to run synthetic. You'll want to make sure there aren't any burs or rough spot from the wire previously installed that might cut a synthetic line. I'll send you a PM with my contact info.

Costman13

Adventurer

I have recently acquired a Warn MX8000 winch. After hooking it all up to give it a test, it did not work. I did some troubleshooting, found that the motor works. After hooking up the solenoid again and tapping on them (there are 4) it kicked on. Therefore a solenoid issue? I gave Warn a call and the solenoid is no longer available. Being this is more of a "budget build" winch (it was given to me), I would rather not spend the $200 on a Warn Contactor Pack. This winch is old and has been used, but has been sitting for a long time (my guess is many years), but after opening it up it appears to be in good shape.

My question is: Is there a solenoid available that will meet the requirements of this winch? You can buy Warn #68379 and #28396 all day long, but will they work for my application? If so, what wiring differences could I expect?

Thank you for your help / insight.

I also posted this over in the "Recovery" Forum as well.

My question is: Is there a solenoid available that will meet the requirements of this winch? You can buy Warn #68379 and #28396 all day long, but will they work for my application? If so, what wiring differences could I expect?

Thank you for your help / insight.

I also posted this over in the "Recovery" Forum as well.

jeverich

Luddite

I'd imagine any solenoid rated for continuous duty in the 300-400 AMP range and an IP water-resistant rating would be suitable.. It'd probably even open up some pretty cool mounting/remote solenoid options too.

Second what Louis said; synthetic line is extremely vulnerable to any kind of burrs or nicks. It's pretty typical for drums on winches that have been used with wire rope to develop ridges and burrs where the wire has tightened up on the drum.

I say take the money that you've (possibly) saved on a free winch and make up a remote mount solenoid with in-cab controls!

Second what Louis said; synthetic line is extremely vulnerable to any kind of burrs or nicks. It's pretty typical for drums on winches that have been used with wire rope to develop ridges and burrs where the wire has tightened up on the drum.

I say take the money that you've (possibly) saved on a free winch and make up a remote mount solenoid with in-cab controls!

Similar threads

- Replies

- 0

- Views

- 234

- Replies

- 4

- Views

- 2K

- Replies

- 0

- Views

- 811

- Replies

- 6

- Views

- 1K