For several years I have been reading posts throughout the Portal and learning a great deal from others' knowledge and experience. As a regular lurker and sometimes "poster", thanks to everyone for the huge body of information that has been collected and special thanks to the organizers and moderators for making this a go-to site for over-landers.

This week I started a project that I thought I would share. I have a '09 Tacoma which has been heavily modified for overland travel. The one area that I have been struggling with is how to carry enough fuel for my not-so fuel efficient rig (even less so because of the weight from gear) . My solution has been a couple of 5 gallon gerry cans on a custom bumper made by Megatech. While Metaltech's work was top-knotch, I wanted a better solution. I could not find anyone building an aftermarket second tank or replacement tank to increase capacity and decided to have one built here in town. The outfit I went to is Custom Exhaust Specialties in Bend, Oregon. They had helped me with a number of other projects including sliders and a custom electrical panel and I knew they did terrific work.

I had contemplated a second tank where the spare tired was carried, but the additional pumping, transfer pumps and/or fills, wiring etc. made me decide to instead replace the Toyota tank with a larger custom built, 14 gauge steel tank. The goal was to squeeze as much fuel into a new baffled tank while maintaining clearance, using the existing vents, pickups, fuel level gauges & wiring. The goal was to also make it as large as possible.

After removing the factory tank, the first order of business was to make a cardboard template of the new tank and fill every possible nook and cranny to maximize capacity. The depth of the tank where the fuel level is measured had to be maintained as well as insuring that the fuel pickup was at the low point in the tank.

From the photos, below, you can see the results and compare the template to the original tank. The template was fitted, refitted and fitted again to the space where the existing tank was located. Most of the extra volume is located in unused space forward of the old tank and by "filling out" some of the old shape.

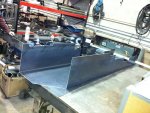

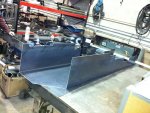

The welding was started yesterday and is depicted below. There is another day of welding (stay tuned for more photos) then the tank will be pressure tested, powder coated and installed. Last step will be to create a full length skid plate out of aluminum to compliment the steel Bud Builts already on the rig. We will go with aluminum to keep the weight down. This is a big tank and much of it is right on centerline so it needs some significant protection.

We have tried to do the math on the new tank to determine capacity but the shape makes this pretty tough. Our best gues-stimates are about 35-37 gallons. We will have to wait to fill it to get an accurate measurement.

More photos to come......

View attachment 85733View attachment 85746View attachment 85745View attachment 85744View attachment 85743View attachment 85742View attachment 85736View attachment 85735View attachment 85734View attachment 85747

re photos as this comes together.

re photos as this comes together.

This week I started a project that I thought I would share. I have a '09 Tacoma which has been heavily modified for overland travel. The one area that I have been struggling with is how to carry enough fuel for my not-so fuel efficient rig (even less so because of the weight from gear) . My solution has been a couple of 5 gallon gerry cans on a custom bumper made by Megatech. While Metaltech's work was top-knotch, I wanted a better solution. I could not find anyone building an aftermarket second tank or replacement tank to increase capacity and decided to have one built here in town. The outfit I went to is Custom Exhaust Specialties in Bend, Oregon. They had helped me with a number of other projects including sliders and a custom electrical panel and I knew they did terrific work.

I had contemplated a second tank where the spare tired was carried, but the additional pumping, transfer pumps and/or fills, wiring etc. made me decide to instead replace the Toyota tank with a larger custom built, 14 gauge steel tank. The goal was to squeeze as much fuel into a new baffled tank while maintaining clearance, using the existing vents, pickups, fuel level gauges & wiring. The goal was to also make it as large as possible.

After removing the factory tank, the first order of business was to make a cardboard template of the new tank and fill every possible nook and cranny to maximize capacity. The depth of the tank where the fuel level is measured had to be maintained as well as insuring that the fuel pickup was at the low point in the tank.

From the photos, below, you can see the results and compare the template to the original tank. The template was fitted, refitted and fitted again to the space where the existing tank was located. Most of the extra volume is located in unused space forward of the old tank and by "filling out" some of the old shape.

The welding was started yesterday and is depicted below. There is another day of welding (stay tuned for more photos) then the tank will be pressure tested, powder coated and installed. Last step will be to create a full length skid plate out of aluminum to compliment the steel Bud Builts already on the rig. We will go with aluminum to keep the weight down. This is a big tank and much of it is right on centerline so it needs some significant protection.

We have tried to do the math on the new tank to determine capacity but the shape makes this pretty tough. Our best gues-stimates are about 35-37 gallons. We will have to wait to fill it to get an accurate measurement.

More photos to come......

View attachment 85733View attachment 85746View attachment 85745View attachment 85744View attachment 85743View attachment 85742View attachment 85736View attachment 85735View attachment 85734View attachment 85747

re photos as this comes together.

re photos as this comes together.