andy.and.beyond

Member

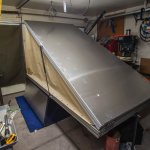

Lost a bit of momentum when it took a week to get the roof so I quit rushing to finish. I decided to use some EPDM weather stripping and bolt the roof rather than glue or tape it. Also welded up some supports for the middle of the roof. I'll be waiting to fully assembly the roof until I get a fan. I had to use the frame to pick up the roof so now I'm moving few steps backwards and took everything off the frame to add weather stripping and start the final assembly. Also decided just to use Plexiglas for the front(lid) and back(against the truck) that way I don't have to add windows for visibility.

Attachments

-

20190101_030320.jpg962.2 KB · Views: 183

20190101_030320.jpg962.2 KB · Views: 183 -

20190104_002908.jpg1.8 MB · Views: 185

20190104_002908.jpg1.8 MB · Views: 185 -

20190104_195332.jpg1.3 MB · Views: 176

20190104_195332.jpg1.3 MB · Views: 176 -

20190104_195408.jpg898.2 KB · Views: 173

20190104_195408.jpg898.2 KB · Views: 173 -

20190106_123927.jpg1.4 MB · Views: 169

20190106_123927.jpg1.4 MB · Views: 169 -

20190107_212511.jpg1.5 MB · Views: 173

20190107_212511.jpg1.5 MB · Views: 173 -

20190110_213946.jpg2.9 MB · Views: 230

20190110_213946.jpg2.9 MB · Views: 230 -

20181228_121824-01.jpg1.3 MB · Views: 234

20181228_121824-01.jpg1.3 MB · Views: 234