PaulJensen

Custom Builder

43 - Wall insulation and Electrical Pre-Wire

(above) Before putting the wall panels on, something was needed to even out the rough fiberglass that is the rear cabin walls... Interlocking foam flooring is attached with contact cement...

(above) The foam also adds another level of insulation...

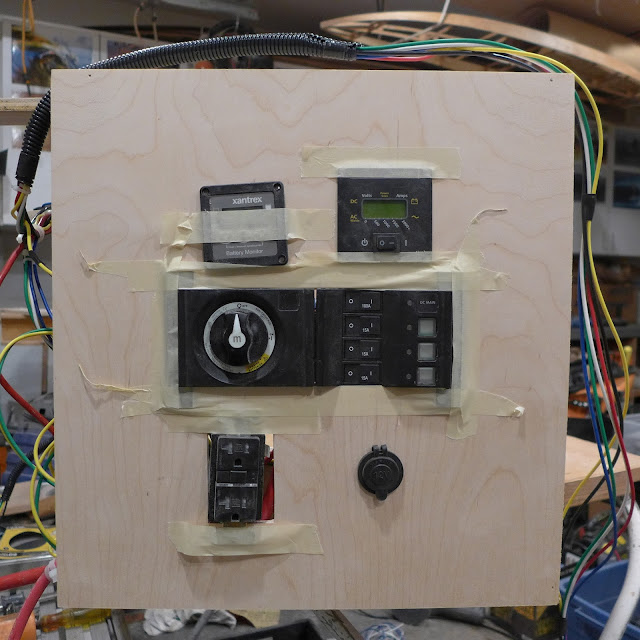

(above) Most of the electrical controls will be at the end of the driver side lower cabinet...

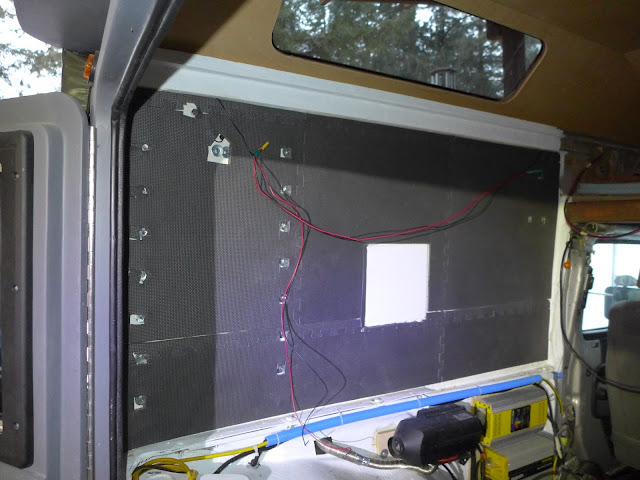

(above) The inside of the rear panel... This is looking from the refrigerator pull-out...

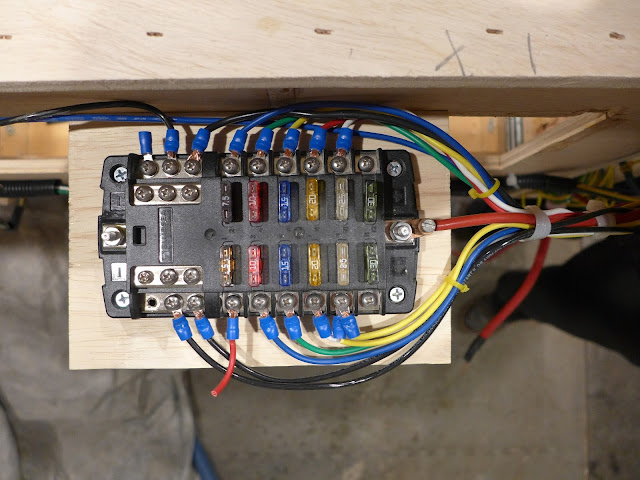

(asbove) The primary fuse panel is just under the rear bench seat cushion... Right now it is pretty close to being ready to permanently install...

(above) Before putting the wall panels on, something was needed to even out the rough fiberglass that is the rear cabin walls... Interlocking foam flooring is attached with contact cement...

(above) The foam also adds another level of insulation...

(above) Most of the electrical controls will be at the end of the driver side lower cabinet...

(above) The inside of the rear panel... This is looking from the refrigerator pull-out...

(asbove) The primary fuse panel is just under the rear bench seat cushion... Right now it is pretty close to being ready to permanently install...