lanceatm

Founder and CEO of EarthCruiser

That time again.

Firstly thank you all for the record setting (yes record setting) response to the EXD-350. We are leaving it a few more days before we publish on other forums.

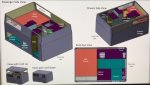

We have had a few people ask how the bed/dinette works, this (bit clunky in solid works as a video file) link I hope better demonstrates what the go is.

EXD-350 Bed to Dinette solid works video

The crew have been playing with this in MDF for a few months, we promised it would not be off the shelf. To convert takes seconds and is at the push of a button.

In the last few days -

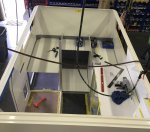

Four walls and floor are bonded inside and out. This way we are not relying on just one substrate or surface.

If the shell did not have windows or entry door it would float, no ply wood glued together for the EXD.

We spend much time and effort on the laminate schedule ( what goes where and when in the lay up process) . These are proprietary processes to the manufacture of our products. We know what needs reinforcing, how much and with what. Different glass mat weights and weaves through out the body unit. There is no metal or timber frame of any kind inside any EarthCruiser product.

With the EXD one sleeps beside windows, not fabric.

We are going to use the Solbian solar panels. No problem driving under trees with the EXD or walking or star gazing on the roof.

Production and quality instructions are the priority at the moment.

Have a great week

Lance

Firstly thank you all for the record setting (yes record setting) response to the EXD-350. We are leaving it a few more days before we publish on other forums.

We have had a few people ask how the bed/dinette works, this (bit clunky in solid works as a video file) link I hope better demonstrates what the go is.

EXD-350 Bed to Dinette solid works video

The crew have been playing with this in MDF for a few months, we promised it would not be off the shelf. To convert takes seconds and is at the push of a button.

In the last few days -

Four walls and floor are bonded inside and out. This way we are not relying on just one substrate or surface.

If the shell did not have windows or entry door it would float, no ply wood glued together for the EXD.

We spend much time and effort on the laminate schedule ( what goes where and when in the lay up process) . These are proprietary processes to the manufacture of our products. We know what needs reinforcing, how much and with what. Different glass mat weights and weaves through out the body unit. There is no metal or timber frame of any kind inside any EarthCruiser product.

With the EXD one sleeps beside windows, not fabric.

We are going to use the Solbian solar panels. No problem driving under trees with the EXD or walking or star gazing on the roof.

Production and quality instructions are the priority at the moment.

Have a great week

Lance

Last edited: