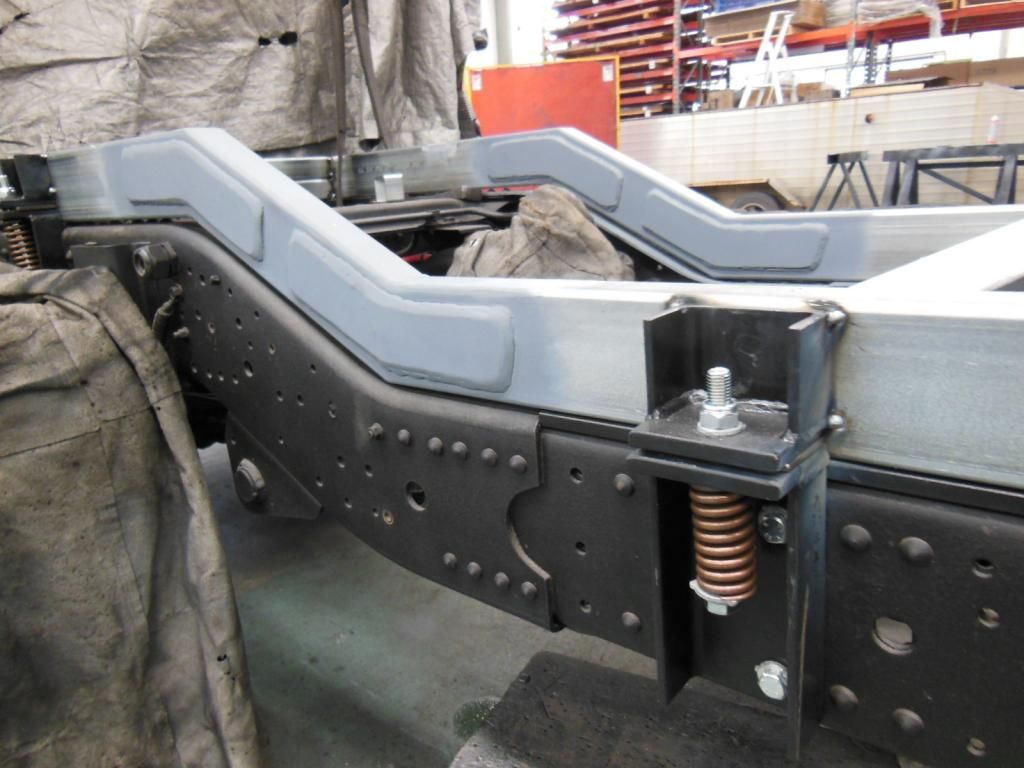

Just got off the phone with the Styromax. Jobs in their system, final quote's been accepted, deposit gets paid next week and their design work starts. They're doing the spring mounted subframe, shell, windows, 2 access hatches for under bed storage and custom entry door. The aluminum used for door and hatch surrounds will be thermally broken to reduce condensation formation and cold inside. Roof and floors will both be 30mm panels, stairs will be insulated and they'll work to ensure this can all fit into a highcube shipping container. Will come with the engineering documentation required to keep Vic Roads happy and LED taillights wired up also embedded in the body.

Their construction method for this is going to be interesting. The main walls will be 80mm panels cut down to 30mm where the roof slides down, leaving a gap for the runners. The roof will be constructed in stages, side runners first made to move up/down, front/rear sections added then all made to move up/down, finally putting the roof panel in and all made to move up/down together. They'll do this movement initially using a crane before I add the actuators later.

They make their panels from scratch, so mounting plates will be embedded into the panel before fiberglass is glued on for cupboards, bed frame supports, roof-racks, actuators and the like. If I could figure out a wiring diagram, conduit can be added into the panels also, but haven't got that bit figured out yet. All the panels will be made out of blue Dow structural foam covered in fiberglass, all sourced from Europe.

Rear wheel carrier, under subframe storage and extra fuel tanks will all need to be added in later.

Their construction method for this is going to be interesting. The main walls will be 80mm panels cut down to 30mm where the roof slides down, leaving a gap for the runners. The roof will be constructed in stages, side runners first made to move up/down, front/rear sections added then all made to move up/down, finally putting the roof panel in and all made to move up/down together. They'll do this movement initially using a crane before I add the actuators later.

They make their panels from scratch, so mounting plates will be embedded into the panel before fiberglass is glued on for cupboards, bed frame supports, roof-racks, actuators and the like. If I could figure out a wiring diagram, conduit can be added into the panels also, but haven't got that bit figured out yet. All the panels will be made out of blue Dow structural foam covered in fiberglass, all sourced from Europe.

Rear wheel carrier, under subframe storage and extra fuel tanks will all need to be added in later.