While I'm in a metal fabricating mode working on the tailgate... I've been thinking about how I might design an "over tub" rack for the M72.

I'd want the rack to be easily removable and stored, so I'd design it so it slipped into receivers on the frame for mounting, and it would be modular so it could be disassembled and stored flat against the wall of the garage.

I'd mount 1-1/4" receivers on the 4 corners of the frame. Could use 2" receivers, but I don't think something that large is necessary. I've pasted some receivers on these photos to show to locations, I'd put them on the side of the frame so they wouldn't interfere with the tongue or the front rack basket. I'd have to mount the tail lights and side marker lights slightly differently because the receivers would go where they're mounted now, but that's not a big deal.

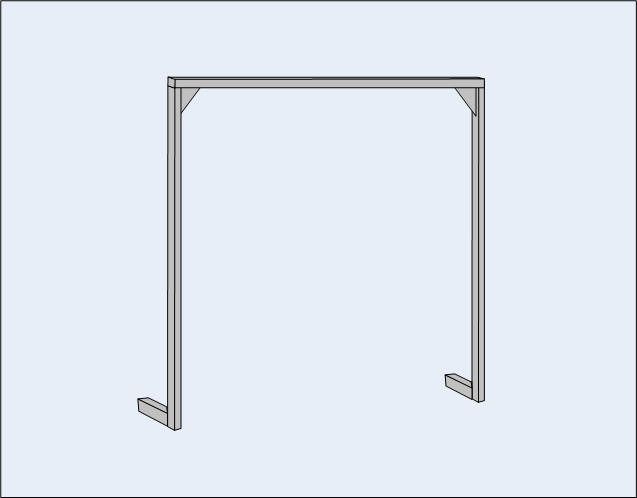

Then I'd make 2 rack ends, something like this:

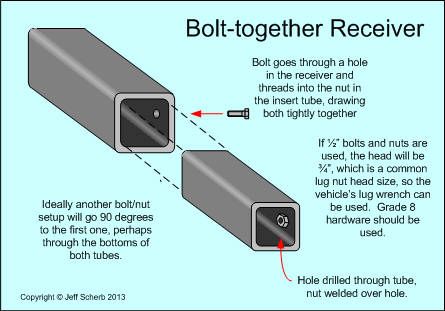

They could both be the same, unless I found some cargo reason why one should be different. They'd be made of 1 1/4" tubing that would fit in the receivers. Corner bracing would in included. Rather than using hitch pins to secure the racks in the receivers, I'd use the bolt-in method to make them rattle- and motion-free:

Then I'd make side bars for the rack, shown below in pink, that bolted in place to the main end racks. Again some corner bracing would be part of the design - building this out of 1-1/4 tubing, there would be some natural flex in the tubing, so bracing against that would be important. It's likely that more bracing than I show in these sketches would be required. I'd probably include some cross-bars across the top for bolting a tent, a rack basket or kayak mounts to.

The drawings above shouldn't be considered a design, they're just idea sketches as I'm thinking about how I might do a removable over-tub rack - these drawings are just me "thinking out loud with my drawing program"... comments on these ideas are welcome.