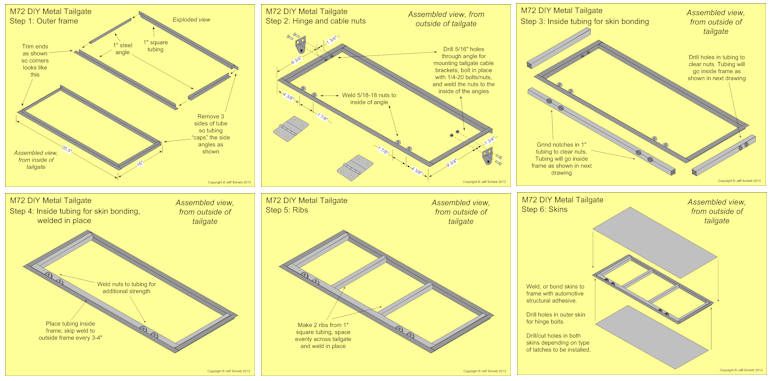

"Overhead" racks for trailers seem to be pretty popular - whether it's to carry kayaks or canoes, extra cargo or maybe a roof-top style tent, an overhead rack can provide access to the storage space inside the trailer while at the same time accommodating large cargo. Here's some few examples I've come across on both military style and Jeep-tub trailers:

Most of the racks I've seen, including the ones pictured above require some fabrication, and specifically welding, that an average DIY-er might not have access to.

I've been thinking about ways to DIY-build an overhead rack for a trailer that wouldn't require welding or any advanced fabrication skills or techniques. So here is one...

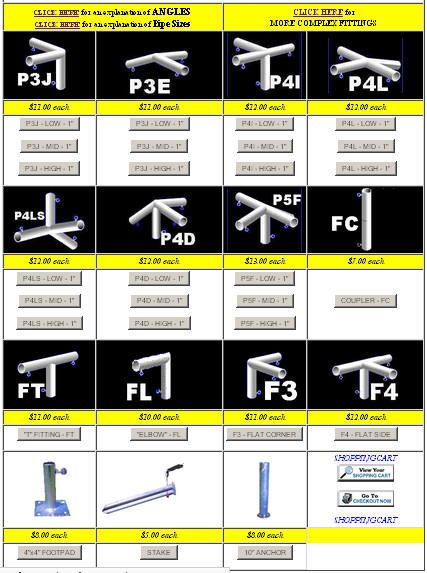

Tent canopies like the ones you can rent for backyard for parties or you might see set up as outdoor Jeep show vendor booths are mostly based on standard fittings that accept common sizes of inexpensive tubing, here's a sample set:

They're commonly available to work with 1" EMT (electrical conduit, 1 3/8" outside diameter), and several larger sizes of chain-link fence tubing, both of which are inexpensive and strong. It would be easy and economical to build an overhead rack using these fittings and 1" EMT (or larger tubing if your strength needs dictated). Here's an example:

I've done the fittings in yellow; this one uses 4 "flat" corners, 4 tees, and four feet, and everything's connected with 1" EMT (in gray).

The rack would be secured to the trailer frame using angle brackets bolted to the frame that the feet could bolt to. Depending on the feet used and the size of the angle brackets, the base of the feet might need to be trimmed a bit because as designed, they're large enough to sit on the ground without sinking in; for this application the size of the base could be smaller.

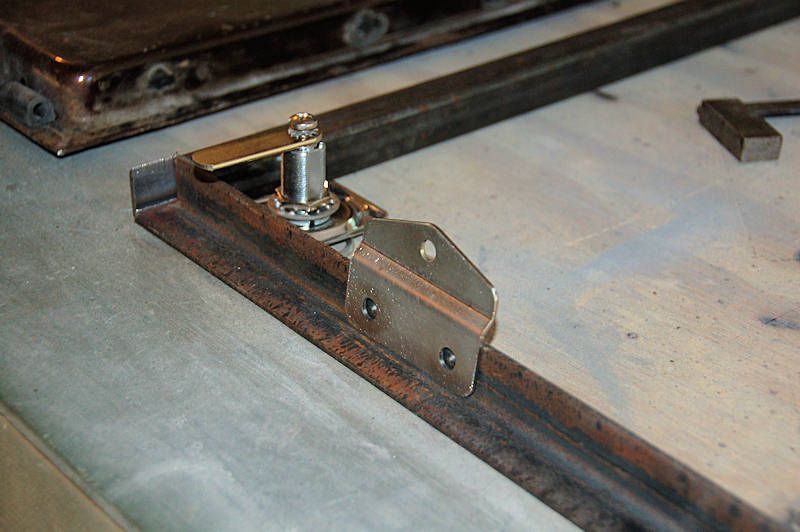

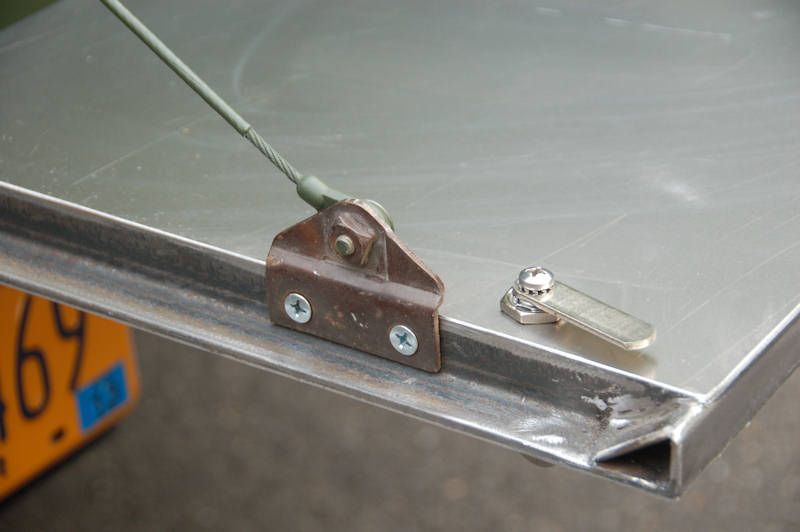

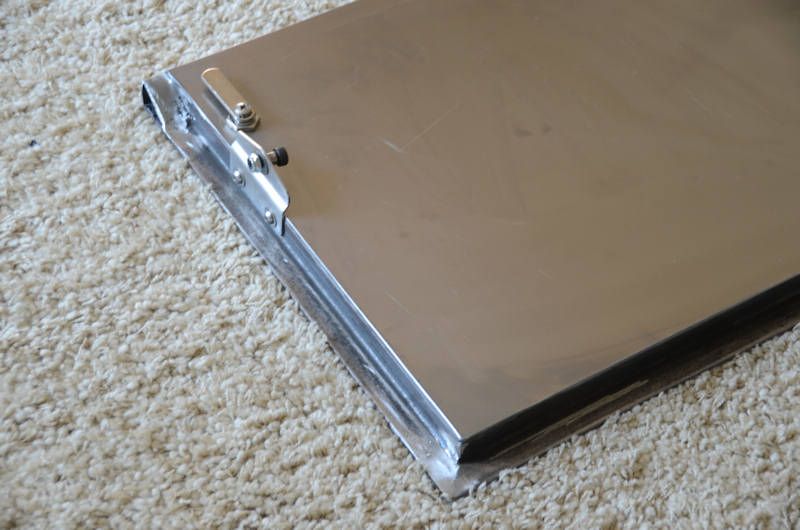

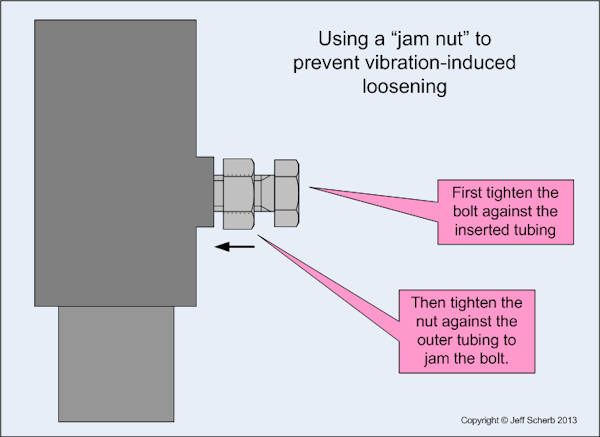

The fittings come with an eye bolt which gets screwed against the tube that's inserted into the fitting, which is fine for a static tent, but for a rack that will be subjected to the vibrations of the road or trail, a more positive lock would be a good idea, so a jam nut setup could be used:

The fittings are pretty affordable, and there's a wide range to pick from so many different configurations of rack could be made. Here are a few sources:

http://www.creativeshelters.com and

http://www.canopymasters.com, and here are some example fitting types: