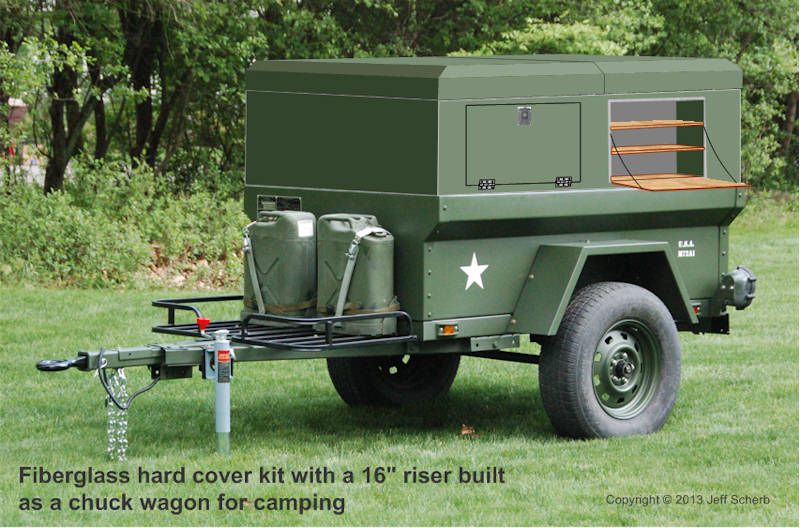

If you've been following this thread, you've seen my fiberglass hard cover/RTT platform:

It's all fiberglass, and I made it in two pieces that bolt together so that it would be small enough to ship UPS Ground.

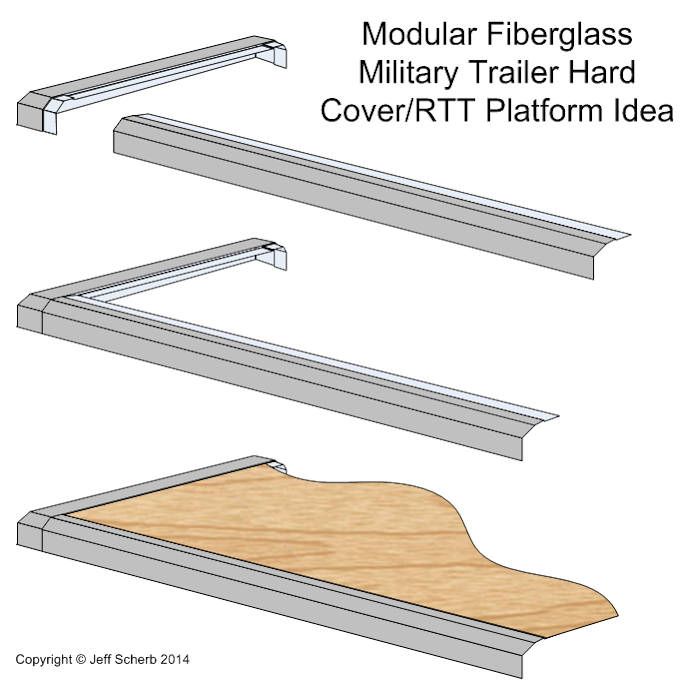

Here's an alternate idea for a cover... it's modular, and consists of four fiberglass pieces (two each of the ends and sides). Only one side and one end are shown in this drawing.

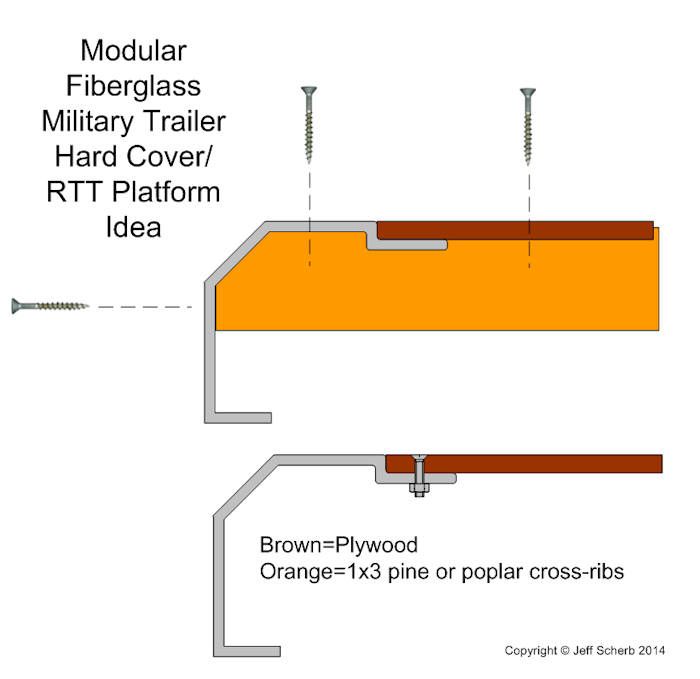

The idea is that these 4 pieces would be much more economical to produce (therefore lower selling price than the earlier design), and would be much less epxensive to ship. The parts would have a recess into which a plywood panel would go:

Probaly a few 1x3 pine or poplar cross-rails would also be added to reinforce the plywood if you planned to carry loads on top (like a roof-top tent).

I'm trying to decide what thickness plywood would make sense for this cover design. I'm trying to balance strength, weight and the quality of easily available plywood.

So I'm posting this to get some input and feedback...

1what do you think of the modular design?

2. In your area, what plywood is available that would make sense for this application. You'd want something that would take a finish well, so preferably not plywood flooring underlayment

. I'm thinking 1/4" or 3/8" plywood, but I don't want it to be something that would have to be special ordered.

What do you guys think?