You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fiberglass M416/M100 Military-style Trailer Tub Kit

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

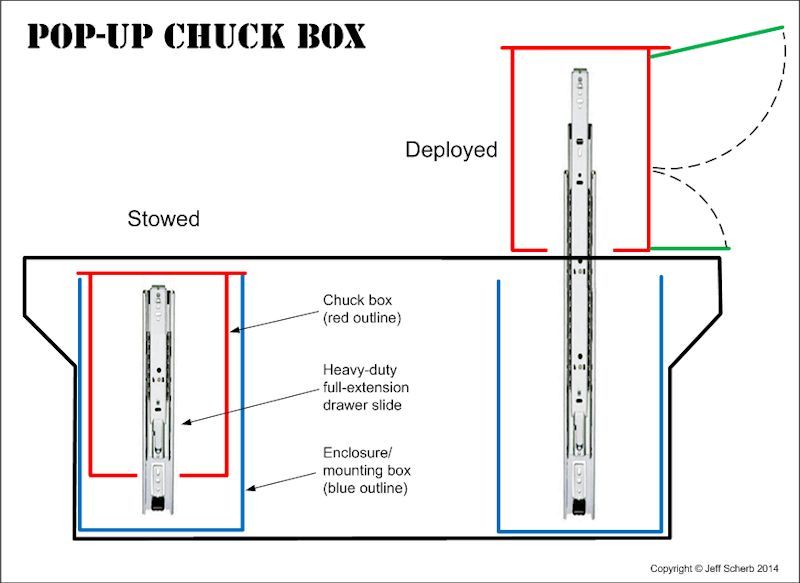

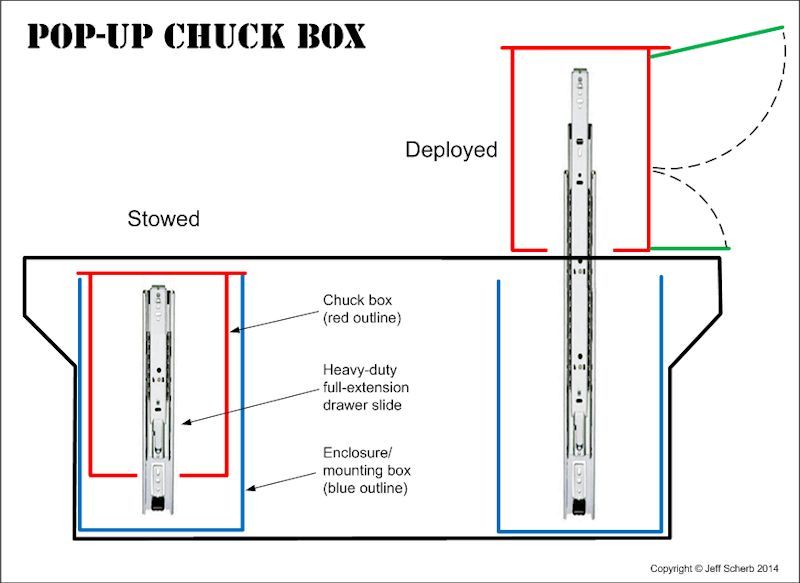

Here's a design for Jack's pop-up chuck box. Jack's requirements were pretty simple, but I added these additional requirements:

So with Jack's requirements plus the above in mind, I came up with the following.

The views above show the box from the back side so the mechanism can be seen, I posted a front view the other day.

It's really nothing more than a box (gray) with a drawer in it (light blue). The only thing unusual about it is that it opens vertically instead of horizontally.

The entire chuck box is self-contained. It can be lifted in and out of the trailer very easily. Perhaps a few latches might be used to hold it in place if it tended to move around when the trailer is in motion. Because it lifts right out, when it's out the trailer can be used for other hauling needs.

Because it is basically a drawer, drawer slides (yellow above) are used for the sliding mechanism.

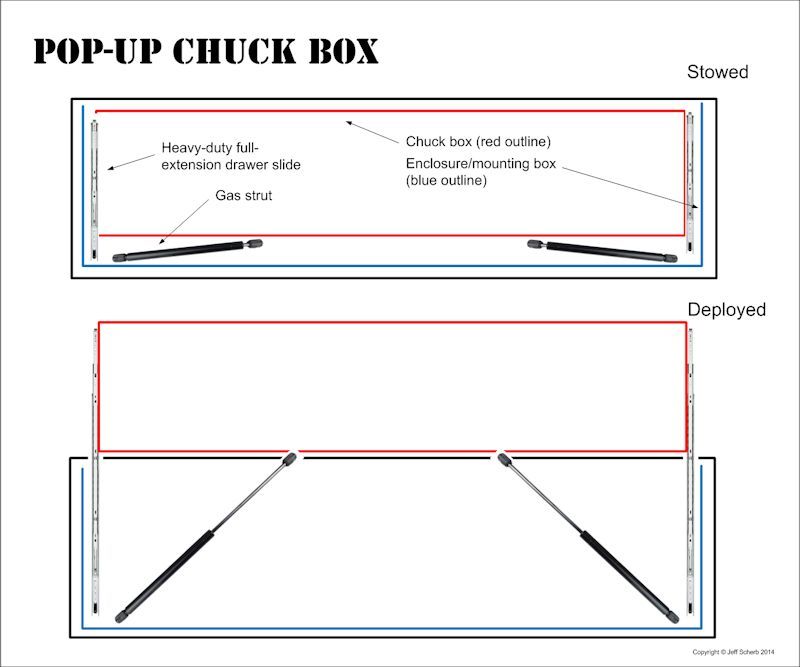

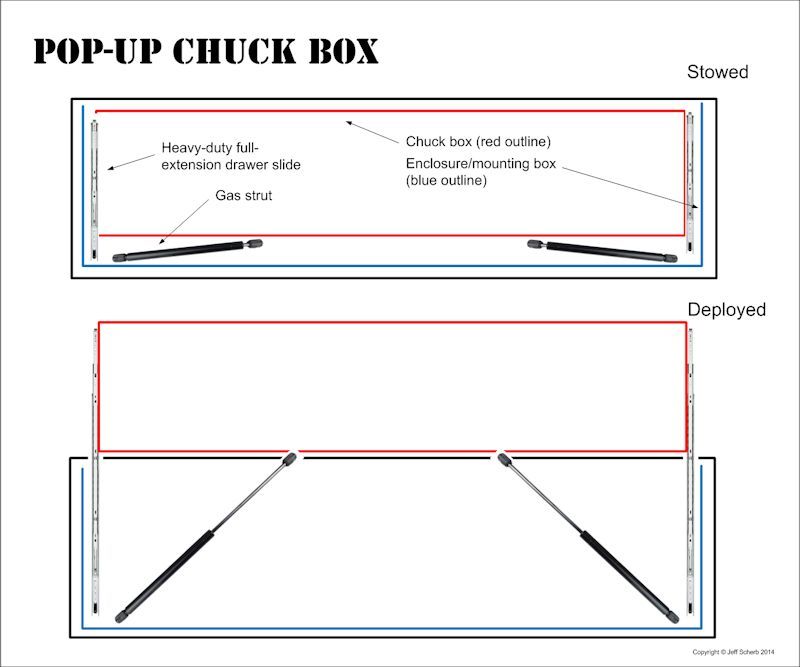

Assisting with the lift is a pair of gas struts. These are inside the box, under the drawer. With the proper struts, the chuck box will be pretty much self-deploying - just like the hatch on a minivan, all you've got to do is start it in motion and the struts will lift it the rest of the way. The drawer slides will ensure smooth and accurate motion.

Here are some end and side views, they should be self-explanatory given the perspective views above.

The "cabinet door" is shown in green. It's in two parts - the bottom part fills the gap between the chuck box and the tub where the tub flares out. A single larger door could be used instead, hinged at the bottom.

The drawer slides will have to be a type that can be used vertically - some slides allow the drawer to be removed by lifting it off the slides, but these won't work in a vertical orientation. Slides with hold the drawer rails captive are called for. The struts need to be chosen based on the weight of the full chuck box and the eight it is to be raised to, bit I'd bet minivan hatch struts would be pretty close to the mark for both strength and length.

In addition to latches to possibly hold the box in place on the floor of the tub, the drawer will probably need latches to hold it in the stowed position. Don't want to hit a bump in the road and have the chuck box pop up .

.

Construction should be pretty straightforward - probably 1/2" plywood for all of the parts would suffice.

Sawhorse-style legs could be constructed so the box could be removed from the trailer and set up on its own legs, perhaps over by a picnic table. Or without the legs, it could be set directly on a picnic table. Or, the box could be attached to a receiver rack and used for tailgating, where it might be impractical to bring the trailer.

I hope this meets Jack's needs.

- The chuck box shouldn't be permanently bolted into the tub -if a chuck box were a permanent installation, other uses of the trailer might be limited. So this design can be lifted in and out very quickly as needed.

- Other gear in the trailer shouldn't need to be unloaded in order to deploy the chuck box. Jack said for his use, unloading first was fine, but it seemed to me that for more general use by other people, it would be best if the chuck box could be deployed without unloading anything first.

- The mechanism hardware should be easily obtainable, inexpensive, reliable and should operate smoothly and easily. Off-the-shelf parts is the goal. This needs to be a DIY project accomplishable with no more tools that it would take to build a Dinoot kit (saw, drill, basic hand tools).

So with Jack's requirements plus the above in mind, I came up with the following.

The views above show the box from the back side so the mechanism can be seen, I posted a front view the other day.

It's really nothing more than a box (gray) with a drawer in it (light blue). The only thing unusual about it is that it opens vertically instead of horizontally.

The entire chuck box is self-contained. It can be lifted in and out of the trailer very easily. Perhaps a few latches might be used to hold it in place if it tended to move around when the trailer is in motion. Because it lifts right out, when it's out the trailer can be used for other hauling needs.

Because it is basically a drawer, drawer slides (yellow above) are used for the sliding mechanism.

Assisting with the lift is a pair of gas struts. These are inside the box, under the drawer. With the proper struts, the chuck box will be pretty much self-deploying - just like the hatch on a minivan, all you've got to do is start it in motion and the struts will lift it the rest of the way. The drawer slides will ensure smooth and accurate motion.

Here are some end and side views, they should be self-explanatory given the perspective views above.

The "cabinet door" is shown in green. It's in two parts - the bottom part fills the gap between the chuck box and the tub where the tub flares out. A single larger door could be used instead, hinged at the bottom.

The drawer slides will have to be a type that can be used vertically - some slides allow the drawer to be removed by lifting it off the slides, but these won't work in a vertical orientation. Slides with hold the drawer rails captive are called for. The struts need to be chosen based on the weight of the full chuck box and the eight it is to be raised to, bit I'd bet minivan hatch struts would be pretty close to the mark for both strength and length.

In addition to latches to possibly hold the box in place on the floor of the tub, the drawer will probably need latches to hold it in the stowed position. Don't want to hit a bump in the road and have the chuck box pop up

Construction should be pretty straightforward - probably 1/2" plywood for all of the parts would suffice.

Sawhorse-style legs could be constructed so the box could be removed from the trailer and set up on its own legs, perhaps over by a picnic table. Or without the legs, it could be set directly on a picnic table. Or, the box could be attached to a receiver rack and used for tailgating, where it might be impractical to bring the trailer.

I hope this meets Jack's needs.

Last edited:

jscherb

Expedition Leader

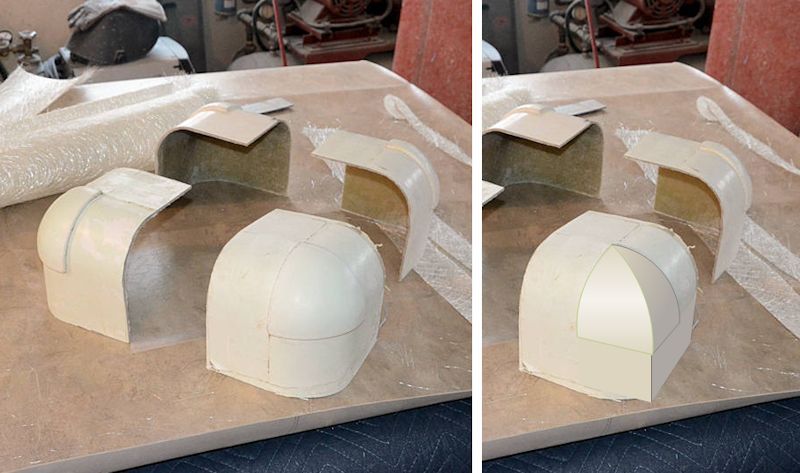

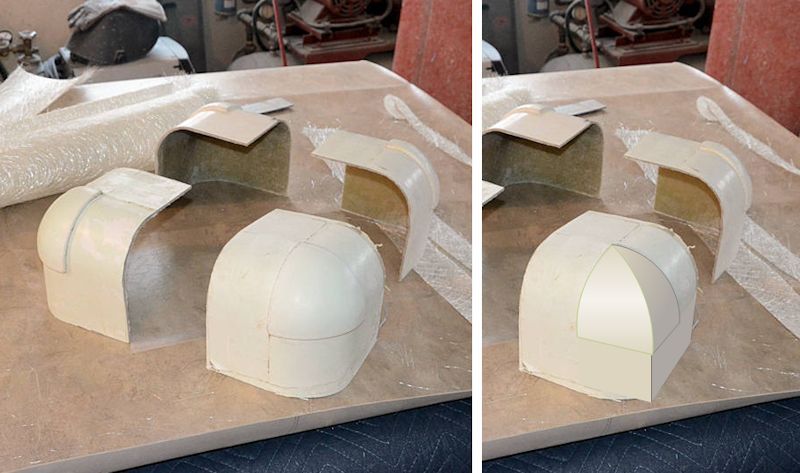

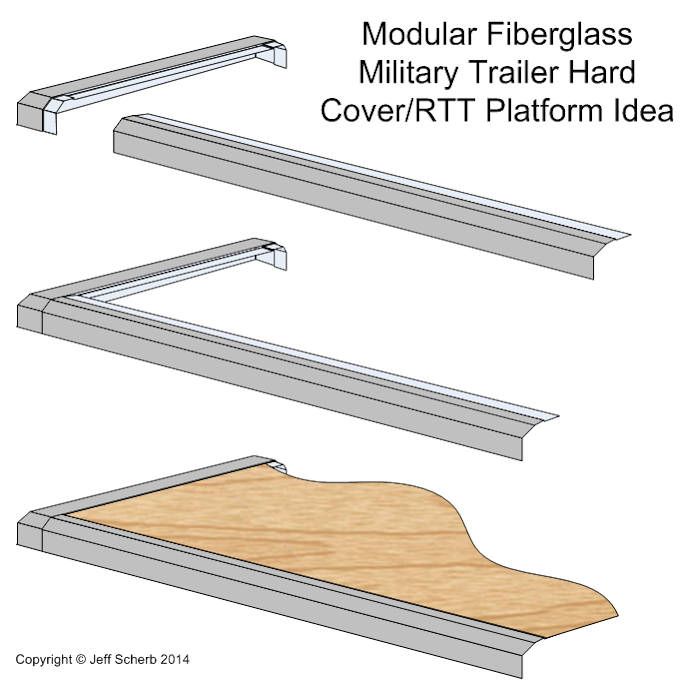

If you've been following my other thread about the "TrailTop" modular trailer topper building components, you've seen how I built a a hard cover for a Jeep-tub/Dinoot J-series trailer:

The cover is strong enough to support a roof-top tent, and it also worked very well as a tilt-up camper top.

The cover was made from these parts - four corner pieces and four straight pieces, plus some wood for framing and some plywood, as shown in one of the photos above.

I've been thinking about how the TrailTop parts might be used to build a similar hard cover for a military-style trailer, but because the military trailers have square corners, the rounded TrailTop corners wouldn't really work on the corners of a military cover.

So I was thinking I could make square corners. On the left are four of the rounded corners, and on the right I've drawn what a square corner would look like:

The square corners would mate with any of the other TrailTop pieces, and with four straight pieces would make a cover that perfectly fitted a military trailer. The first drawing is shown unpainted to illustrate the assembly of the parts.

And painted:

The same parts could also be used to build a chuck wagon/root-top tent platform:

The cover is strong enough to support a roof-top tent, and it also worked very well as a tilt-up camper top.

The cover was made from these parts - four corner pieces and four straight pieces, plus some wood for framing and some plywood, as shown in one of the photos above.

I've been thinking about how the TrailTop parts might be used to build a similar hard cover for a military-style trailer, but because the military trailers have square corners, the rounded TrailTop corners wouldn't really work on the corners of a military cover.

So I was thinking I could make square corners. On the left are four of the rounded corners, and on the right I've drawn what a square corner would look like:

The square corners would mate with any of the other TrailTop pieces, and with four straight pieces would make a cover that perfectly fitted a military trailer. The first drawing is shown unpainted to illustrate the assembly of the parts.

And painted:

The same parts could also be used to build a chuck wagon/root-top tent platform:

brian90744

American Trekker

When will these ideas be available?

You have fantastic idea and plans, however many will not reach us end users, the vendor you licensed your ideas/molds to will not produce these. Yes the fiberglass tub & fenders seem to keep him in business. The TrailTop" modular trailer topper is great BUT years away from production, same as the fiberglass lid design. Your thread keeps us hopeful and keeps on growing.

thanks=brian

You have fantastic idea and plans, however many will not reach us end users, the vendor you licensed your ideas/molds to will not produce these. Yes the fiberglass tub & fenders seem to keep him in business. The TrailTop" modular trailer topper is great BUT years away from production, same as the fiberglass lid design. Your thread keeps us hopeful and keeps on growing.

thanks=brian

Last edited:

jscherb

Expedition Leader

You have fantastic idea and plans, however many will not reach us end users, the vendor you licensed your ideas/molds to will not produce these. Yes the fiberglass tub & fenders seem to keep him in business. The TrailTop" modular trailer topper is great BUT years away from production, same as the fiberglass lid design. You thread keeps us hopeful and keeps on growing.

thanks=brian

I just design this stuff and build prototypes as a hobby, but because I'm not in business to sell stuff, I can't make things get to market, sorry. I don't know what the plans of the company that licensed my tub designs might be, so I can't comment on that. But if any other company or any person is interested in marketing either the TrailTop system or one of the military trailer covers I've designed, I'd be happy to talk to them about it. I've got a relationship with a fiberglass production company that would be happy to manufacture any of these parts, so it would be easy for any company/anyone to work with me and this fiberglass company to bring any of these fiberglass ideas to market.

Maybe if there was enough interest for the trail top system. We could get a production run. Not sure how many would need to be produced to make it feasible. but something like say a run of 100 kits. This I would say would be part diy as the kit would only include the fiberglass corners and edges. You would construct it yourself.

jscherb

Expedition Leader

Maybe if there was enough interest for the trail top system. We could get a production run. Not sure how many would need to be produced to make it feasible. but something like say a run of 100 kits. This I would say would be part diy as the kit would only include the fiberglass corners and edges. You would construct it yourself.

I doubt there would be demand for 100 kits. But if someone wanted take the lead on a production run, I'd be happy to talk to them about it and put them in touch with the fiberglass production company that is interested in doing the manufacturing. It's not something I'd be interested in doing myself, I just do this as a hobby and I'm not interested in getting into the business of selling kits or parts.

brian90744

American Trekker

NO production NO sales

A good vendor would make 10 of each trail top system and 10 trailer lid parts and see how they sell, If you don't have any parts you don't have any sales. I'm sure 10 would not break the vendor cash flow. Just looking at the number of hits to this thread must be some idea as to the need. Your designs are useless with out production and sales.

A good vendor would make 10 of each trail top system and 10 trailer lid parts and see how they sell, If you don't have any parts you don't have any sales. I'm sure 10 would not break the vendor cash flow. Just looking at the number of hits to this thread must be some idea as to the need. Your designs are useless with out production and sales.

jscherb

Expedition Leader

A good vendor would make 10 of each trail top system and 10 trailer lid parts and see how they sell, If you don't have any parts you don't have any sales. I'm sure 10 would not break the vendor cash flow. Just looking at the number of hits to this thread must be some idea as to the need. Your designs are useless with out production and sales.

Sometimes it's hard to tell from a post what the writer's real intention is... but I'm sorry if I said or did something to offend you, seems like there's some anger in your post.

brian90744

American Trekker

I'm NOT upset with you, I would just like to see your ideas in the market place. sorry you took my reply as an offence.=brian

Sometimes it's hard to tell from a post what the writer's real intention is... but I'm sorry if I said or did something to offend you, seems like there's some anger in your post.

jscherb

Expedition Leader

I'm NOT upset with you, I would just like to see your ideas in the market place. sorry you took my reply as an offence.=brian

Thanks for the clarification, I just wanted to make sure I didn't do anything to offend

If I may ask, if the TrailTop parts make it to market, what project would you plan to build with the parts? And would you be interested in being an early tester?

brian90744

American Trekker

jscherb

Expedition Leader

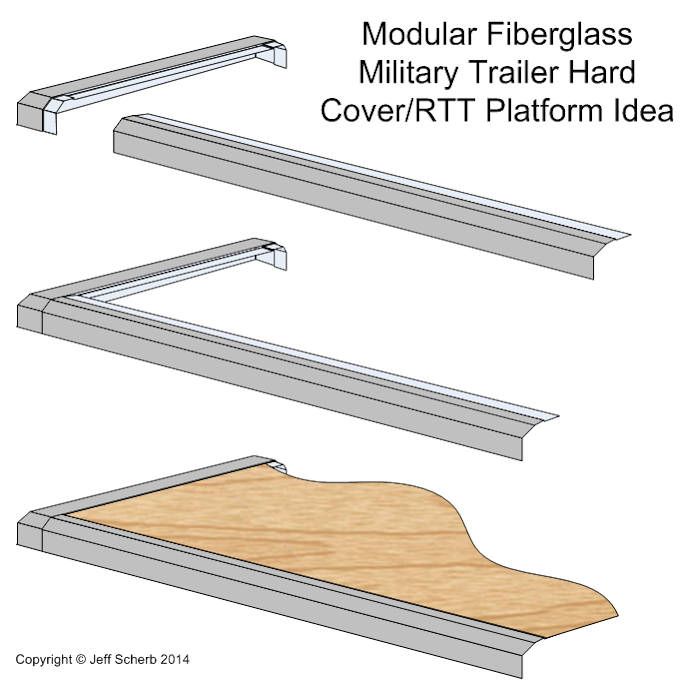

I've done three different fiberglass cover designs for the military trailer.

My original is a two-piece fiberglass design.

The two pieces get bolted together into one, although it is possible to hinge them separately.

The second design would look the same as the two-piece when finished but I did it as a modular design so it should be less expensive to manufacture and ship the parts, but there's a little more DIY in the assembly. It would consist of four fiberglass pieces - two end pieces and two side pieces, and a center panel of 1/4" plywood. There would also be a few wood cross-ribs under the plywood, the size and number of which would depend on the load you planned to carry on the cover. Here's a concept drawing of what one would look like, the plywood is shown unpainted in these drawings.

How the parts would go together:

And the third design is the one I posted the other day, it uses the TrailTop parts so it's got rounded edges like the cover for my yellow Jeep-tub trailer. I'll repost the drawings I posted the other day, the first one is unpainted to show the construction. Construction is similar to the one above, using plywood and some wood cross-ribs. Because it uses the TrailTop parts there's some economy of scale in manufacturing - the production mold cost could be ammortized over both military trailer market and the rest of the market for TrailTop parts.

The cover for the Jeep-tub trailer:

My original is a two-piece fiberglass design.

The two pieces get bolted together into one, although it is possible to hinge them separately.

The second design would look the same as the two-piece when finished but I did it as a modular design so it should be less expensive to manufacture and ship the parts, but there's a little more DIY in the assembly. It would consist of four fiberglass pieces - two end pieces and two side pieces, and a center panel of 1/4" plywood. There would also be a few wood cross-ribs under the plywood, the size and number of which would depend on the load you planned to carry on the cover. Here's a concept drawing of what one would look like, the plywood is shown unpainted in these drawings.

How the parts would go together:

And the third design is the one I posted the other day, it uses the TrailTop parts so it's got rounded edges like the cover for my yellow Jeep-tub trailer. I'll repost the drawings I posted the other day, the first one is unpainted to show the construction. Construction is similar to the one above, using plywood and some wood cross-ribs. Because it uses the TrailTop parts there's some economy of scale in manufacturing - the production mold cost could be ammortized over both military trailer market and the rest of the market for TrailTop parts.

The cover for the Jeep-tub trailer:

Similar threads

- Replies

- 0

- Views

- 354

- Replies

- 2

- Views

- 845

- Replies

- 0

- Views

- 390

- Replies

- 4

- Views

- 1K