You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

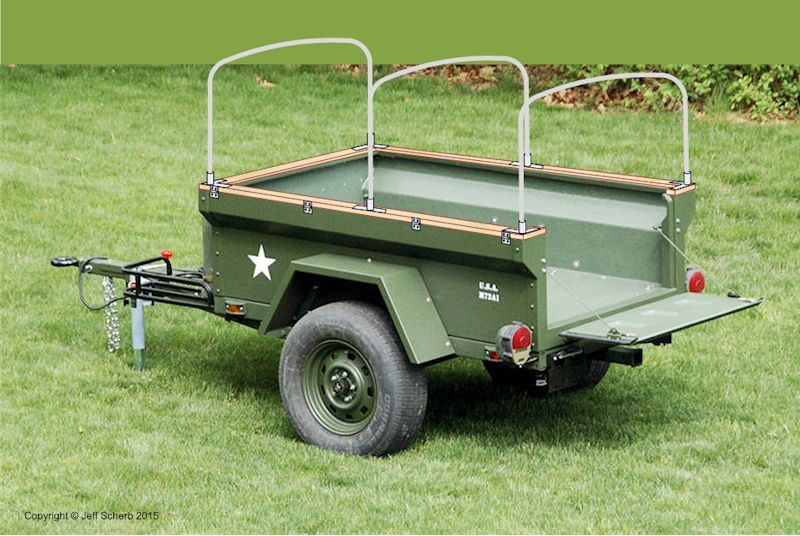

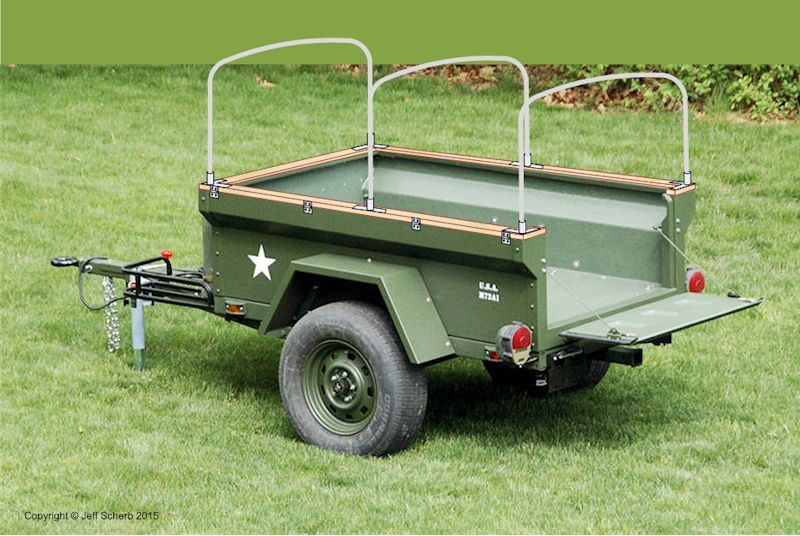

Fiberglass M416/M100 Military-style Trailer Tub Kit

- Thread starter jscherb

- Start date

jscherb

Expedition Leader

Another example I found in a thread here (http://www.expeditionportal.com/for...o-Trailer-based-on-M416-4800-in-Greenville-SC)

The top raises and there's a sleeping platform at the top of the tub, which works for the person who owned it because he's 5'9". A military trailer tub just isn't long enough for someone like me to sleep in, but I don't plan anything like that anyway, I'm just looking to build a simple covered wagon top.

The top raises and there's a sleeping platform at the top of the tub, which works for the person who owned it because he's 5'9". A military trailer tub just isn't long enough for someone like me to sleep in, but I don't plan anything like that anyway, I'm just looking to build a simple covered wagon top.

jscherb

Expedition Leader

I made up a set of bows for the covered wagon. They're 3/4" EMT conduit. They're taller than I plan to build the cover, I haven't trimmed them to height yet. I'll trim them after I set them on the trailer so I can decide exactly the height I want.

Some bracing will be added between the bows, I haven't gotten to that yet.

The bows fit into simple bow sockets I made up from hardware store parts.

The sockets could be bolted directly to the tub, but I plan to bolt them to a wooden frame that'll sit on top of the tub. The frame will enable the cover to be lifted off in one piece, but it would also allow the cover to be hinged like the one I posted photos of a few days ago. I've already got the removable hinges on the hard cover, I can mount another set of hinge parts on the covered wagon frame and use the same style latches on the other side so it attaches to the tub in the same way as the hard cover - that way no extra hardware is required on the tub and no extra clamps are required to mount either the hard cover or the covered wagon top.

Some bracing will be added between the bows, I haven't gotten to that yet.

The bows fit into simple bow sockets I made up from hardware store parts.

The sockets could be bolted directly to the tub, but I plan to bolt them to a wooden frame that'll sit on top of the tub. The frame will enable the cover to be lifted off in one piece, but it would also allow the cover to be hinged like the one I posted photos of a few days ago. I've already got the removable hinges on the hard cover, I can mount another set of hinge parts on the covered wagon frame and use the same style latches on the other side so it attaches to the tub in the same way as the hard cover - that way no extra hardware is required on the tub and no extra clamps are required to mount either the hard cover or the covered wagon top.

Last edited:

jscherb

Expedition Leader

The bow sockets will be attached to a frame that will sit on top of the tub. The could be attached directly to the tub, but by attaching them to a removable frame, I can easily swap the covered wagon top out for the hard cover/tent platform. The frame will attach to the same hinges and latches used for the hard cover. The hinges are removable like those on a Jeep door, so the covered wagon frame will just slip into those hinges, no tools required.

Snaps to secure the bottom of the canvas will be placed along the edge of the wooden frame, so there won't need to be any new holes made in the tub.

Snaps to secure the bottom of the canvas will be placed along the edge of the wooden frame, so there won't need to be any new holes made in the tub.

jscherb

Expedition Leader

I'm considering two different designs for reinforcing the bow structure. The first design uses horizontal boards similar to the ones the original Bantam BT3C trailer had. They'd be attached to the bows with conduit clamps. The drawing shows one board on each side, but if I use this method I might decide to install two on each side.

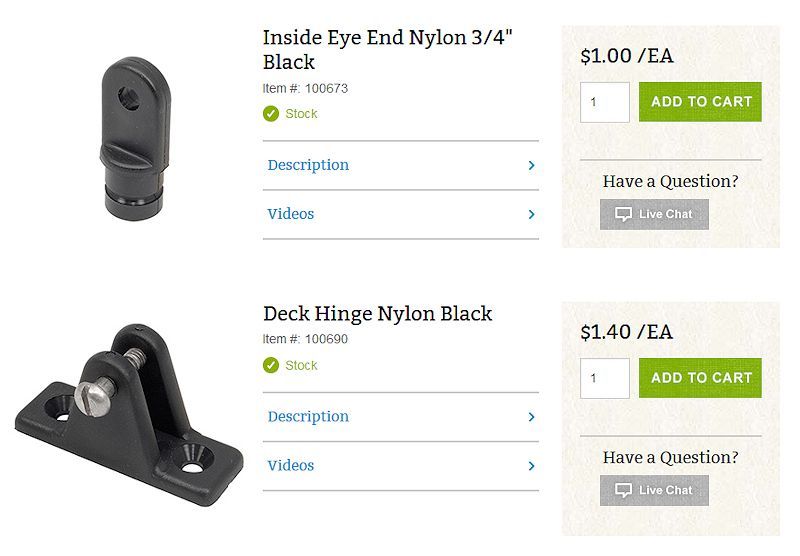

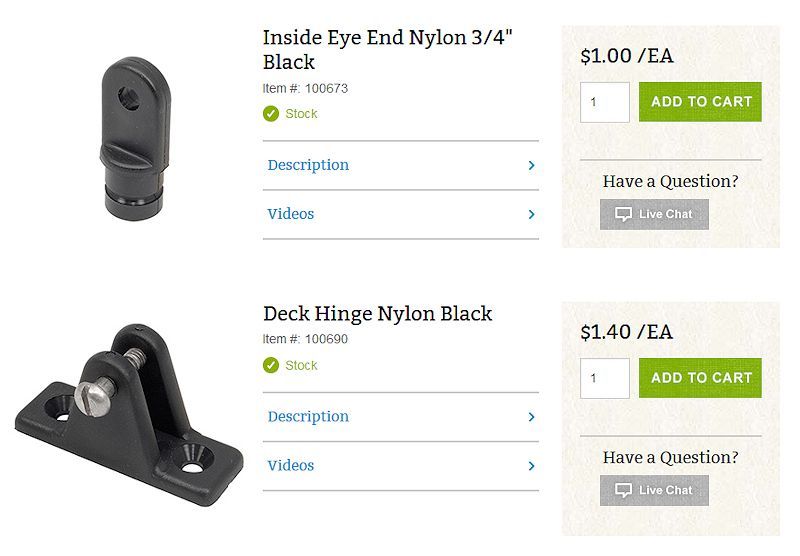

The second alternative is to use marine bow eye ends and deck hinges. The 3/4" size eye end is a perfect fit for 1/2" EMT conduit.

The installation would look something like this:

The center bow won't need reinforcement in this design; it'll be held in place by the canvas.

A nice feature of the second design is that the bow eyes are easily unhooked, so the cover could be removed from the bow sockets and folded flat for storage in the garage.

A nice feature of the horizontal board design is that if I make roll-up side panels in the canvas top, there won't be any reinforcing rods in the way of access to the inside of the tub from the side when the panels are rolled up.

The second alternative is to use marine bow eye ends and deck hinges. The 3/4" size eye end is a perfect fit for 1/2" EMT conduit.

The installation would look something like this:

The center bow won't need reinforcement in this design; it'll be held in place by the canvas.

A nice feature of the second design is that the bow eyes are easily unhooked, so the cover could be removed from the bow sockets and folded flat for storage in the garage.

A nice feature of the horizontal board design is that if I make roll-up side panels in the canvas top, there won't be any reinforcing rods in the way of access to the inside of the tub from the side when the panels are rolled up.

oscar the grouch

Jeep Nut

Im looking at putting together one of these m series tubs. I cant seem to find a lid tho. can you point me in the right direction?

jscherb

Expedition Leader

The company that sells the tub kits sells a really nice tonneau cover. It's got a frame that clamps to the top of the tub, and the tonneau snaps onto the frame, so it's a no-drill installation.Im looking at putting together one of these m series tubs. I cant seem to find a lid tho. can you point me in the right direction?

If you're looking for a fiberglass hard cover/tent platform like the one on my M-series prototype, unfortunately that isn't in production. I only molded the one prototype for my trailer.

On the tventuring forum, there is a thread about making hard covers from plywood, that's a good way to go: http://tventuring.com/trailerforum/thread-159.html

oscar the grouch

Jeep Nut

thanks. I want to mount a tent on the lid so i guess its learning how to wood work once i have my trailer built.

jscherb

Expedition Leader

thanks. I want to mount a tent on the lid so i guess its learning how to wood work once i have my trailer built.

Some people mount their tents on rack bars mounted to the tub sides. People who do this often use the tonneau cover on top of the tub, it allows easy access to the gear inside.

jscherb

Expedition Leader

Seems like you could make a spot on the center hoop for the plastic brackets to live such that the supports would be horizontal in the same location as the boards but you would still be able to pull them apart and lay the whole mess flat for storage... Best of both!

There are lots of ways it could be done with the bow end/deck hinge parts I posted, I'm still playing around with different ideas.

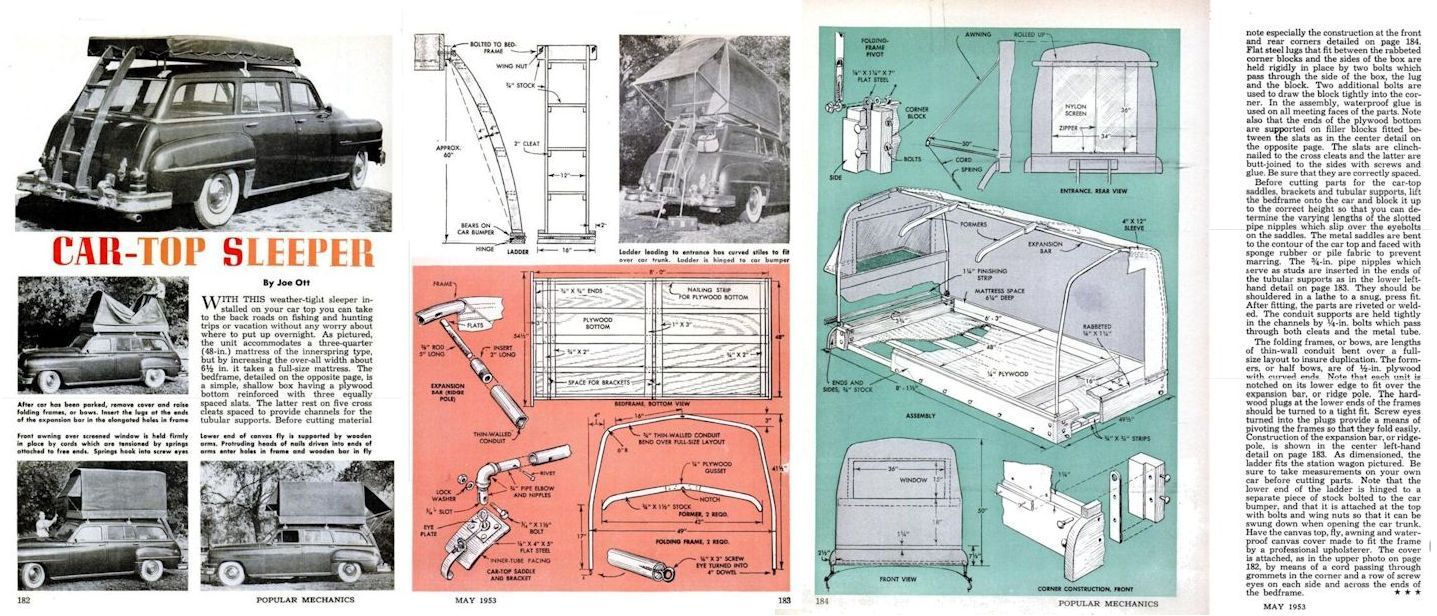

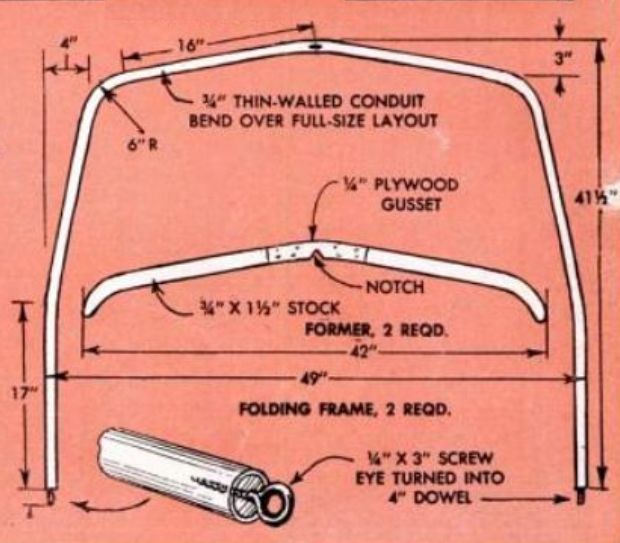

Here's an idea... it's a plan for one that folds down... it isn't actually a trailer top though, it's a "Car-Top Sleeper" project published in the May 1953 issue of Popular Mechanics, but it could be easily adapted to a trailer.

I edited a few of the photos in the article onto a photo of my trailer:

The 50's plan uses wooden plugs and screw eyes but the bow eyes I posted earlier would work great, be easy to implement and look very nice.

jscherb

Expedition Leader

I've gotten a bunch of questions in the last few weeks about the fiberglass cover I made for this trailer, and twice in the last 24 hours I've been asked if it would fit an original M416 tub.

The short answer is yes, the cover would fit an M416.

The fiberglass tub and the M416 differ in one way when it comes to the top of the tub - the fiberglass tub has a flange at the top that faces inwards, and the M416 flange faces outwards. The fiberglass cover is designed to fit flush with the outside edges of the fiberglass tub, you can see how it is flush in this photo:

It's very simple to install the cover on an M416 with an outward-facing tub flange though, here's a drawing showing how it would work. All that would need to be done is to bolt an outward-facing wooden flange (shown in gray in the drawing to make it clear) to the bottom of the fiberglass cover.

The styling of the outward facing flange added to the cover would match the styling of the outward-facing flange on the tub, so I think the cover would look very nice on the M416.

Hinges, latches and gas struts aren't shown in the drawing above, but they wouldn't be hard to add.

The short answer is yes, the cover would fit an M416.

The fiberglass tub and the M416 differ in one way when it comes to the top of the tub - the fiberglass tub has a flange at the top that faces inwards, and the M416 flange faces outwards. The fiberglass cover is designed to fit flush with the outside edges of the fiberglass tub, you can see how it is flush in this photo:

It's very simple to install the cover on an M416 with an outward-facing tub flange though, here's a drawing showing how it would work. All that would need to be done is to bolt an outward-facing wooden flange (shown in gray in the drawing to make it clear) to the bottom of the fiberglass cover.

The styling of the outward facing flange added to the cover would match the styling of the outward-facing flange on the tub, so I think the cover would look very nice on the M416.

Hinges, latches and gas struts aren't shown in the drawing above, but they wouldn't be hard to add.

brian90744

American Trekker

mold=modular F/G military trl Hard cover RRT platform

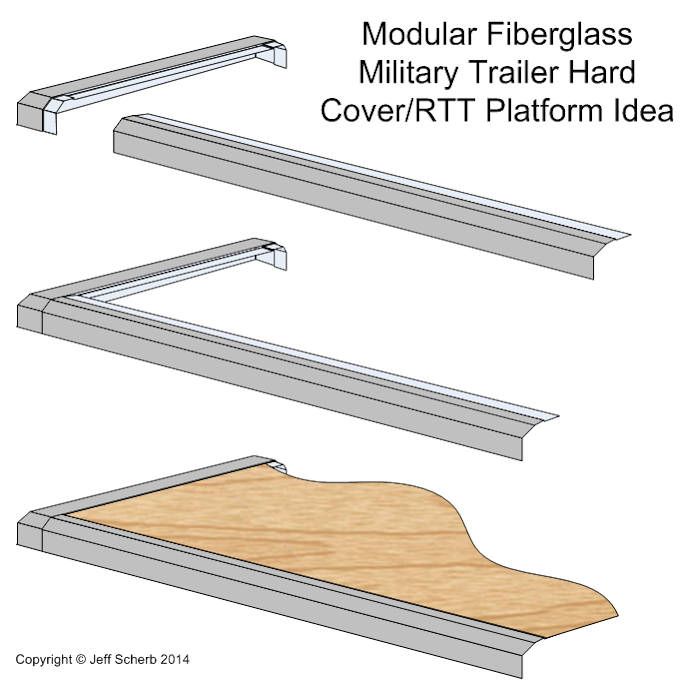

Did you make the molds for 4-piece military trailer cover kit. It used 4 fiberglass side/end rail pieces with a 1/4"plywood center panel. The component design means that it can be manufactured and ship very affordably; the plywood insert reduces the shipping cost (the builder supplies his own plywood) and also the overall cost of assembling a cover.

If you sold the idea for these molds, To who, I want to buy a st for my M416. Great idea.=brian

Did you make the molds for 4-piece military trailer cover kit. It used 4 fiberglass side/end rail pieces with a 1/4"plywood center panel. The component design means that it can be manufactured and ship very affordably; the plywood insert reduces the shipping cost (the builder supplies his own plywood) and also the overall cost of assembling a cover.

If you sold the idea for these molds, To who, I want to buy a st for my M416. Great idea.=brian

jscherb

Expedition Leader

Did you make the molds for 4-piece military trailer cover kit. It used 4 fiberglass side/end rail pieces with a 1/4"plywood center panel. The component design means that it can be manufactured and ship very affordably; the plywood insert reduces the shipping cost (the builder supplies his own plywood) and also the overall cost of assembling a cover.

If you sold the idea for these molds, To who, I want to buy a st for my M416. Great idea.=brian

You're asking about this one?

There was a company that wanted to market it, but they ended up deciding not to go ahead so I didn't make the molds.

I did make up parts for a slightly different version which used the rounded edge parts from my TrailTop modular component design, this photo shows a corner piece and a short straight piece on a military trailer:

Here what a cover made up from the rounded components look like on a Jeep-tub trailer, although this one's got rounded corners to match the Jeep tub corners and the parts shown above have square corners to match the corners of the military tub. It shows how the components look when assembled with plywood and finished:

What it looks like before a finish is applied:

If any of these cover components get picked up by a company to be offered for sale I'll let people know.

Similar threads

- Replies

- 0

- Views

- 375

- Replies

- 2

- Views

- 954

- Replies

- 0

- Views

- 403

- Replies

- 4

- Views

- 2K