jscherb

Expedition Leader

You Sir have tremendous talent.....thank you for sharing these projects!

Sent from my Roof Top Tent

Thanks! Glad you enjoy the projects

You Sir have tremendous talent.....thank you for sharing these projects!

Sent from my Roof Top Tent

I'd choose woodland over ACU any day. ACU= gravel vomit.

You know this soft top design may lead to a revival of soft topped expedition trailers.

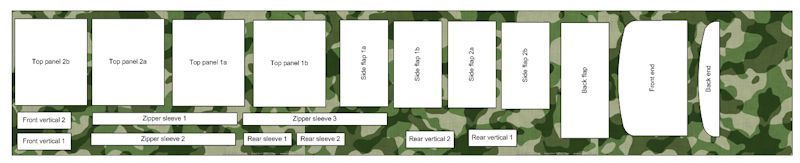

I'm working on finding just the right fabric for the covered wagon project. My criteria include: a camo pattern/color that looks good on the trailer, mostly synthetic (polyester/nylon/acrylic), heavy military "canvas" look and feel, and coated fabric for waterproofing. I want to use something fairly heavy because I'm designing this to be well behaved at freeway speeds and I think heavier fabrics will fare better at speed.

Two camo patterns are very common in fabrics that meet these criteria - something called "Woodland" camo (at right below, similar to military BDU camo), and ACU ("Army Combat Uniform") camo, below left are some samples from a fabric supplier's web site:

A larger view of a typical Woodland camo pattern:

The color isn't very accurate on the web site, here's an actual sample of the ACU camo photographed against the trailer:

I'm leaning towards something like the ACU camo because the colors look good with the color of the trailer, even though it isn't "period correct" for a military trailer like this and the pattern is kind of small. The Woodland pattern just doesn't seem military enough to me, I don't think the military ever used a pattern like that. On the other hand, I don't think the ACU pattern is used on real military vehicles, but I could be wrong about that. Input welcome!

I've got a little time to decide which fabric to use, between other projects I'm working on that have actual deadlines, some mold-making I'm doing for my JK Safari cab project, and a road trip to Utah for Easter Jeep Safari, I won't be able to start sewing for a bit.

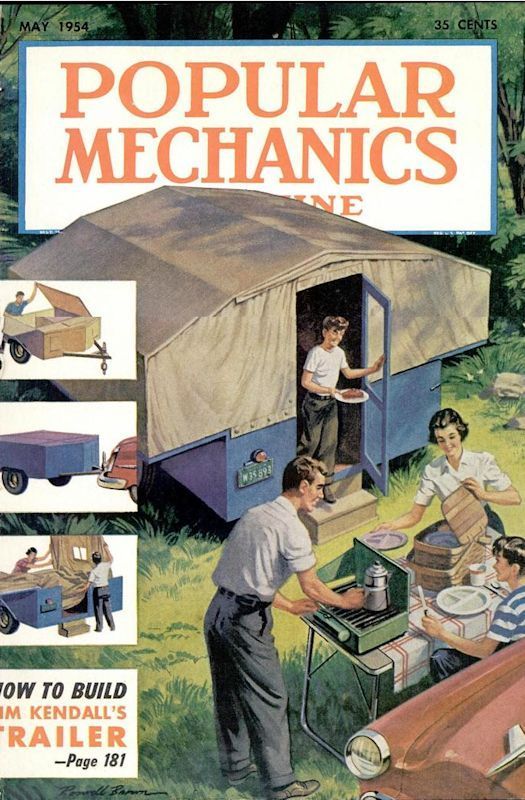

You might be on to something there... today the cover of the May 1954 issue caught my eye:

It's a two part article with plans and instructions for building the fold-out camper pictured on the cover. Seems to me it's a good design to put on top of a small offroad trailer, so I did that (digitally). Here it is on my Jeep-tub trailer - it's not the most elegant photo-hack I've ever done, but it gets the concept across:

On a 6'6" Dinoot Extended trailer, you could easily get a sleeping platform that's as big as a king-sized bed if you did a minimal single platform across the tub, or two sleeping platforms if you did beds on either side of the tub.

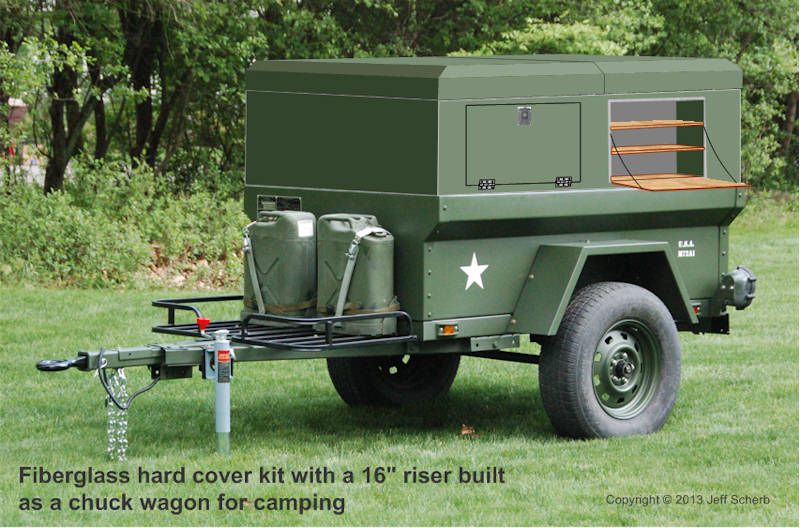

It could also be done on a military trailer, here it is on mine.

The complete May and June 1954 issues of Popular Mechanics are online in Google books, and with the complete plans and instructions there it wouldn't take much work to change a few dimensions and make this idea work on one of these trailers.

This thread and trailer are so damn cool that I had to join just to tell you that.

Ok, fanboy comment finished. I'm curious to know what it would look like if you took another tub, flipped it over and put it on top as a cap. Throw a rack on top and it could look pretty cool. If nothing else, it would be an easy way to add a cap and more capacity, though a new door/gate would have to be fabricated.