You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flatbed and composite panel build on Dodge 2500

- Thread starter Jeep

- Start date

Can't really say anything that has not already been said.

Excellent documentation, attention to detail and a clean organised shop

Destructive testing, quality welds with marine grade aluminium, Aerogels and composite panels

ROPS certification and frame impact/torsional testing

Very cool **** man

:beer:

Excellent documentation, attention to detail and a clean organised shop

Destructive testing, quality welds with marine grade aluminium, Aerogels and composite panels

ROPS certification and frame impact/torsional testing

Very cool **** man

:beer:

Thanks for all the positive comments guys, it's a bit of a job keeping it all together but I have a great team that deserves a lot of credit. Without them I would not be able to do the things I do.

Since the cabinets are in a CAD design phase and I'm having a really awesome (I think) cabinet builder take care of the project I had some time to tackle a few little items.

I couldn't find a heater that I was impressed with, BTU's are funny, based on things like coolant flow, temperature drop, air flow, and most of the fans have a considerably high amp draw. I decided to build a heater using a heat exchanger that is common used on school busses in the front area by the door, we work on a lot of busses and prep them for severe cold and the front is never an issue so I'm going on experience for the choice. The Bergstrom heater core is a triple pass unit with a very dense aluminum fin arrangement. Being as the Espar has 3/4" hose outlets, I cut the 1" inlet/outlets down on the core, machined a couple of brass 3/5"x3/4" not brass hose barbs down for a nice tight fit and silver soldered them into the core. The tubes look a little dirty but it is mostly just flux residue that is like glass, it cleaned up pretty good post pic. I drew and router cut a heater bracket that supports and mounts the heater and fans out of .125 aluminum, after I spent a few late nights digging up a couple of really high output processor cooling fans. 2 fans, .48 amp draw each .96 total, very quiet, 130 CFM each for a theoretic 260 CFM. Plugged them in and they move a nice column of air, they are very quiet, and the low amp draw is super attractive especially since this unit will be on solar and I don't plan on carrying a generator.

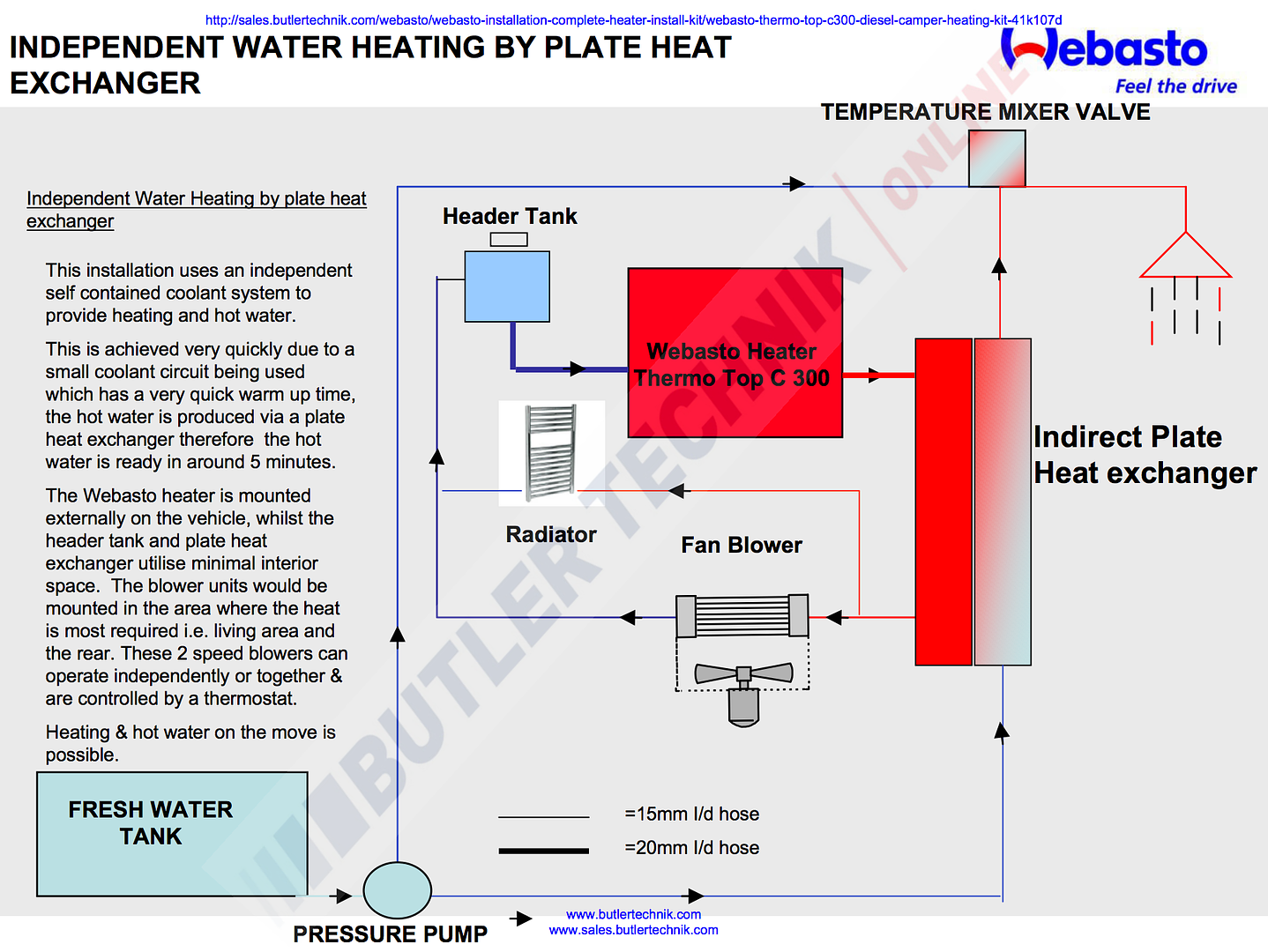

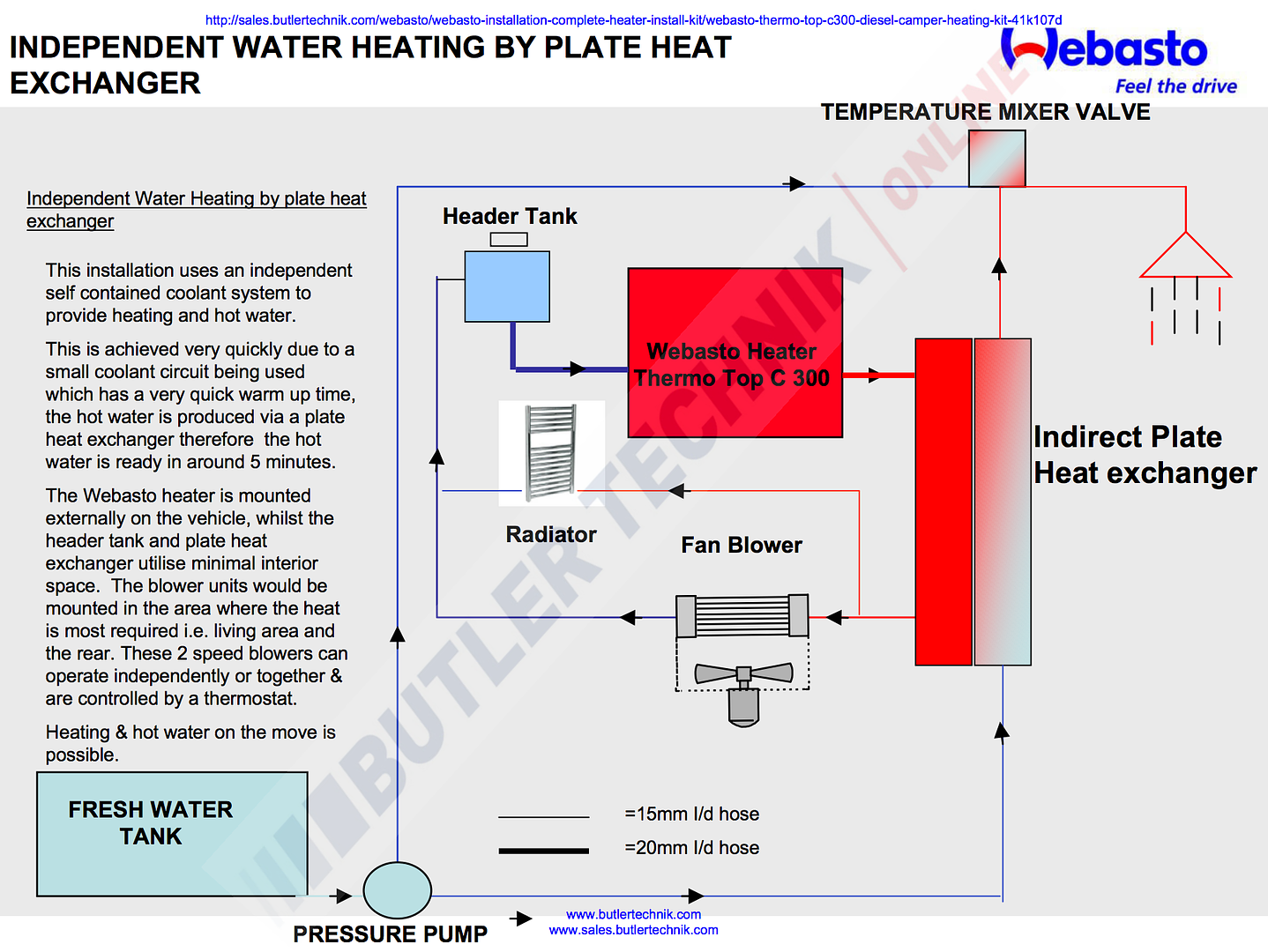

The equipment list has changed a bit, I am now using a Wallace XC Duo cook top, diesel, altitude compensating, and it can also function as an auxiliary heater with the fan lid. Wallace is owned by Espar and we are a volume Espar dealer and their quality and support is unsurpassed in the diesel heating world. The heating system has changed as well, I am no longer using the Isotherm hot water heater, I have gone to a plate type heat exchanger combined with the Espar, and the custom heater I'm building. I got the idea from Gary Wescott so credit where credit is due, after a quick chat with him we have endless hot water (or at least 35 gallons of it!), a bunch more space, and a bunch less weight. So with the Hydronic heating system, and the Wallace heater lid on the cook top we have double redundant heat.

Weekend project….bolt it together.

Since the cabinets are in a CAD design phase and I'm having a really awesome (I think) cabinet builder take care of the project I had some time to tackle a few little items.

I couldn't find a heater that I was impressed with, BTU's are funny, based on things like coolant flow, temperature drop, air flow, and most of the fans have a considerably high amp draw. I decided to build a heater using a heat exchanger that is common used on school busses in the front area by the door, we work on a lot of busses and prep them for severe cold and the front is never an issue so I'm going on experience for the choice. The Bergstrom heater core is a triple pass unit with a very dense aluminum fin arrangement. Being as the Espar has 3/4" hose outlets, I cut the 1" inlet/outlets down on the core, machined a couple of brass 3/5"x3/4" not brass hose barbs down for a nice tight fit and silver soldered them into the core. The tubes look a little dirty but it is mostly just flux residue that is like glass, it cleaned up pretty good post pic. I drew and router cut a heater bracket that supports and mounts the heater and fans out of .125 aluminum, after I spent a few late nights digging up a couple of really high output processor cooling fans. 2 fans, .48 amp draw each .96 total, very quiet, 130 CFM each for a theoretic 260 CFM. Plugged them in and they move a nice column of air, they are very quiet, and the low amp draw is super attractive especially since this unit will be on solar and I don't plan on carrying a generator.

The equipment list has changed a bit, I am now using a Wallace XC Duo cook top, diesel, altitude compensating, and it can also function as an auxiliary heater with the fan lid. Wallace is owned by Espar and we are a volume Espar dealer and their quality and support is unsurpassed in the diesel heating world. The heating system has changed as well, I am no longer using the Isotherm hot water heater, I have gone to a plate type heat exchanger combined with the Espar, and the custom heater I'm building. I got the idea from Gary Wescott so credit where credit is due, after a quick chat with him we have endless hot water (or at least 35 gallons of it!), a bunch more space, and a bunch less weight. So with the Hydronic heating system, and the Wallace heater lid on the cook top we have double redundant heat.

Weekend project….bolt it together.

If you have not purchased your Wallace yet, may I suggest the Kerosene version instead. In the states at least, Kerosene does not have additives in it like ULSD does and actually offers a few more BTU's per unit of volume than diesel. The diesel unit may run on K-1, but I am fairly certain that Wallace offers a Kerosene unit specifically.

Check with Espar and see if they have the same or if their diesel units are K-1 compatible. Finally, kerosene is about 50 - 60 cents per gallon cheaper here than red dye diesel, at least in bulk form. Your stoves and heaters won't burn much, so that may be a non issue for you.

I like the plate heater idea for the hot water, makes one wonder why no one offers something like that. Typically, RV and marine hot water production comes with quite a bulky package.

Interested to hear what you think about Bergstrom, as I was just looking at their cabin A/C units (12V) for an un-related project last night.

Cheers

Check with Espar and see if they have the same or if their diesel units are K-1 compatible. Finally, kerosene is about 50 - 60 cents per gallon cheaper here than red dye diesel, at least in bulk form. Your stoves and heaters won't burn much, so that may be a non issue for you.

I like the plate heater idea for the hot water, makes one wonder why no one offers something like that. Typically, RV and marine hot water production comes with quite a bulky package.

Interested to hear what you think about Bergstrom, as I was just looking at their cabin A/C units (12V) for an un-related project last night.

Cheers

I'm going with the diesel unit for 1 fuel to feed everything, the kerosene unit is available and I did look at it, very nice little cook top but I don't want to deal with another fuel. As it is there will be a small propane barbeque in the truck which will most likely get used 10X as much as the cooktop! The XC is also designed and certified (important if you want to export) for vehicular use so it draws fresh air from the outside, and is designed for ULSD.

The Bergstrom stuff is a little primitive but very durable, one of the few things we never have to fix. I like the triple pass heat exchanger myself, seems to get a lot more heat out of the unit than a double which only makes sense, the air is in the exchanger for a longer period of time.

The Bergstrom stuff is a little primitive but very durable, one of the few things we never have to fix. I like the triple pass heat exchanger myself, seems to get a lot more heat out of the unit than a double which only makes sense, the air is in the exchanger for a longer period of time.

Last edited:

The heating system has changed as well, I am no longer using the Isotherm hot water heater, I have gone to a plate type heat exchanger combined with the Espar, and the custom heater I'm building. I got the idea from Gary Wescott so credit where credit is due, after a quick chat with him we have endless hot water (or at least 35 gallons of it!), a bunch more space, and a bunch less weight. So with the Hydronic heating system, and the Wallace heater lid on the cook top we have double redundant heat.

Looking great sir, excited to see this come together. Particularly the flat plate. We had been reading on this and considering, my only hesitation being what am I missing, or why havent more people done it? Particularly in the marine environment? Seems an obvious choice, but I can't find many examples.

This unit from the UK has nice thermostatic mixing integration.

Healeyjet

Explorer

Agree totally on the cooktop. We are going with the induction cooktop but our propane stove will get way more use I think. This is actually the one item I have concerns about in our build so it will be good to get some real world feedback once you start using the Wallace cooktop.

Ward

Ward

ps - nice schematic of a plate exchange system here from the same UK site

http://butlertechnik.com/download/A6/Webasto_heater_Therm_Top_C_300_5kw_Hot_water_Heating_System.pdf

http://butlertechnik.com/download/A6/Webasto_heater_Therm_Top_C_300_5kw_Hot_water_Heating_System.pdf

That's exactly the plan, it is surprising how physically small the heat exchanger can be, I worked with an application engineer from GEA and then Brazetek, and both came up with very close conclusions so I made my choice on a Brazetek unit as the footprint fit the application better.

I originally had a 8 gallon Isotherm hot water tank going in and the space requirements of the Espar, heat exchanger, heating radiator, fit in less space than the hot water tank, so it freed up a good chunk of space. All of the listed components are actually in line with each other and fit nice and tight.

For weight savings I lose the 42 pounds for the water tank, plus 30 litters of water which weighs 66 lbs, the heat exchanger weighs 6 pounds so theoretically I will lose 102 pounds.

And according to the engineers, one of the guys I dealt with had some good experience with Espar and Webasto heat sources, if everything is sized right 5 minutes will have water at 90 celsius. This system can be tied into a vehicle heating loop as well for permanent mount bodies. Gary's experience was also a strong contributing factor to the redesign, same heater, same application, similar size of camper body, similar panel system, and real world use by a highly respected explorer made the decision easier.

As for the cook top Ward, we usually do almost everything outside, even though we have the inside equipment we are usually doing things on the barbecue and an outside cooktop. We are AC hogs, my wife uses an electric toaster and an electric coffee maker inside the 650, and this camper will actually have more amp hours and a better inverter along with more solar so I'm going to pick up an induction cook top to try out as well.

Some more real world experience: This year we did not fire up the generator on our F-650 once, zero hours. Last couple of trips we made coffee on the stove instead of the coffee maker. Temperatures dropped down to -9C, or 15F at night and the furnace ran a lot, and it's not a real energy efficient furnace but it does produce some good heat, and the shorter days up here give us less charging time especially with a flat mounted panel, but it still kept the battery bank up reasonably enough to go for 4 days on its own. Equipment is:

2-Group 31 AGM batteries

Samlex 150 Watt solar panel with 30 Amp charge controller

Xantrex 3000 Watt inverter

So nothing real fancy.

I originally had a 8 gallon Isotherm hot water tank going in and the space requirements of the Espar, heat exchanger, heating radiator, fit in less space than the hot water tank, so it freed up a good chunk of space. All of the listed components are actually in line with each other and fit nice and tight.

For weight savings I lose the 42 pounds for the water tank, plus 30 litters of water which weighs 66 lbs, the heat exchanger weighs 6 pounds so theoretically I will lose 102 pounds.

And according to the engineers, one of the guys I dealt with had some good experience with Espar and Webasto heat sources, if everything is sized right 5 minutes will have water at 90 celsius. This system can be tied into a vehicle heating loop as well for permanent mount bodies. Gary's experience was also a strong contributing factor to the redesign, same heater, same application, similar size of camper body, similar panel system, and real world use by a highly respected explorer made the decision easier.

As for the cook top Ward, we usually do almost everything outside, even though we have the inside equipment we are usually doing things on the barbecue and an outside cooktop. We are AC hogs, my wife uses an electric toaster and an electric coffee maker inside the 650, and this camper will actually have more amp hours and a better inverter along with more solar so I'm going to pick up an induction cook top to try out as well.

Some more real world experience: This year we did not fire up the generator on our F-650 once, zero hours. Last couple of trips we made coffee on the stove instead of the coffee maker. Temperatures dropped down to -9C, or 15F at night and the furnace ran a lot, and it's not a real energy efficient furnace but it does produce some good heat, and the shorter days up here give us less charging time especially with a flat mounted panel, but it still kept the battery bank up reasonably enough to go for 4 days on its own. Equipment is:

2-Group 31 AGM batteries

Samlex 150 Watt solar panel with 30 Amp charge controller

Xantrex 3000 Watt inverter

So nothing real fancy.

I was leaning towards Tru Induction for the reasons you posted Dzl. I shouldn't really be amazed by the amount of cheap crap on the market but there is a lot, and I'm amazed! I've had a saying for a long time "******t to shine is 10%" looks to apply here too.

After pouring through paperwork for way too many hours for a weekend, I took a mental break and finished putting the heater together, 50 000 BTU core, 260 CFM, 17 1000 BTU output on Espar D5, what will it put out? The heat exchanger mounts on top for a nice compact set up that will only have about 3' of coolant hose between everything. Also had the grey tank powder coated and installed that too, Sika 252 set up in locations where it can be cut if the tank ever needs to be removed. There was a big part of me wanting to use way too much 252, as I have no idea why it would ever need to come out!

The heater looks small, overall dimensions are 12" high x 18" wide.

The heater looks small, overall dimensions are 12" high x 18" wide.

Last edited:

Similar threads

- Replies

- 15

- Views

- 1K

- Replies

- 18

- Views

- 2K