You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fleetwood Neon Modified for off road

- Thread starter MountainD

- Start date

Jeepinaaron

Adventurer

Does this mount allow you to lower the awning any so that it can be used with the ARB awning room, or mosquito room.

MountainD

Adventurer

Yeah! And super simple, too. So right now the "male" part (for lack of better word) is on the awning and the female part is on the trailer. I have an extender that I have to finish welding, that has the same male part on a 3' piece of flat aluminum 3" wide bar stock and the female part on the opposite side at the opposite end. All I have to do is slip it into where the awning would go and it puts another female coupler 3' lower. Slip the awning into that coupler. I'll post picks after I finish the welds-- super simple, just not in a hurry as I don't have the room yet...

Desert Rat 1

Adventurer

Great job! I like that awning concept, I'll have to look into it more as I need to replace mine. Are you going to bolt them up, besides gluing?

MountainD

Adventurer

It is bolted through through the top with 2x5/16" bolts that go through to a plate that runs the entire length between the two attachments. It is also bolted with a 5/16" bolt through the vertical side and temporarily has a fender washer to soon be replaced with a backing plate. It is all Sikka-flex "glued" to the top as well, but we all know that is just a thin skin, so the bolting was an absolute for me. It was raining when we arrived in camp last weekend and the campsite dictated that the awning be on the opposite side. I loosened the retaining screws and it lifted right out and then right into the other side. Very happy with the arrangement. Very. Here are a few picks of it "in action" and then the mounting plate that runs the length of the inside as well as the fender washer. You can see some sag in the mounting bar as I have some accessories that I am mounting before I get it fully dialed in for the inside. I also need to trim the bolts. but one thing at a time

MountainD

Adventurer

Everything has been going great but the weight sure creeps up on you when you load things up! I am upgrading the electric over hydraulic brake actuator to a 1600 psi for the season and selling off the 1200 psi version. Put it in the for sale section, here are the deets:

HBA12 1200PSI electric over hydraulic brake actuator. Works great, no problems. So I am selling it for $425 including shipping to any of the lower 48

HBA12 1200PSI electric over hydraulic brake actuator. Works great, no problems. So I am selling it for $425 including shipping to any of the lower 48

sn0wrunner

New member

Awesome build! Lots of inspiration for my cobalt.

You may have already posted, but what is your frame height? The lower of the two frames.

You may have already posted, but what is your frame height? The lower of the two frames.

Last edited:

MountainD

Adventurer

It is just shy of 22" off the ground when loaded, so pretty good ground clearance. My tires are 33's, so the axle is really the low point at about 16". I'm not counting the springs as I just aim the tires and go over what would typically hit them--pretty good at that with the shorter tongue length and short wheel base of the D90.

My advice, is to keep things as light as possible. I'll get it weighed this year, but I am pretty sure I am in the 2K-2500lb range. Truck has a little trouble getting it over passes. Weight adds up quick--heck, I may be even at the 2500lb range when fully loaded--hard to tell without an actual weighing of it. I kept thinking about all the ways that I can shave off a few hundred pounds and finally just said screw it---and I bought (this weekend) a GM GEN IV L9H engine/trans off ebay (basically an LS3). It is a 6.2L 403HP 417ft-lb torque motor that I am putting into the D90. Not worried about the weight anymore...

My advice, is to keep things as light as possible. I'll get it weighed this year, but I am pretty sure I am in the 2K-2500lb range. Truck has a little trouble getting it over passes. Weight adds up quick--heck, I may be even at the 2500lb range when fully loaded--hard to tell without an actual weighing of it. I kept thinking about all the ways that I can shave off a few hundred pounds and finally just said screw it---and I bought (this weekend) a GM GEN IV L9H engine/trans off ebay (basically an LS3). It is a 6.2L 403HP 417ft-lb torque motor that I am putting into the D90. Not worried about the weight anymore...

Last edited:

MountainD

Adventurer

Now that the truck is back on the road with the LS3 engine, I replaced the electric over hydraulic brake actuator with a 1600psi version. Got everything hooked back up (rewired in the brake controller for the new engine harness) and I am back in business. Drives amazing--don't even know it is behind the truck on acceleration and the braking is SOOOO much better.

That all said, I just saw the new release for the ARB Jack:

ARB Jack: https://expeditionportal.com/arb-releases-new-jack/

https://www.arb.com.au/recovery/hi-lift-jacks-accessories/jack/

Not quite out yet, but I have to get me one of these.... I have almost been clobbered multiple times by my HiLift and I will lay it to rest as soon as a good alternate is released...

That all said, I just saw the new release for the ARB Jack:

ARB Jack: https://expeditionportal.com/arb-releases-new-jack/

https://www.arb.com.au/recovery/hi-lift-jacks-accessories/jack/

Not quite out yet, but I have to get me one of these.... I have almost been clobbered multiple times by my HiLift and I will lay it to rest as soon as a good alternate is released...

VanIsle_Greg

I think I need a bigger truck!

Now that the truck is back on the road with the LS3 engine, I replaced the electric over hydraulic brake actuator with a 1600psi version. Got everything hooked back up (rewired in the brake controller for the new engine harness) and I am back in business. Drives amazing--don't even know it is behind the truck on acceleration and the braking is SOOOO much better.

That all said, I just saw the new release for the ARB Jack:

View attachment 440696

ARB Jack: https://expeditionportal.com/arb-releases-new-jack/

https://www.arb.com.au/recovery/hi-lift-jacks-accessories/jack/

Not quite out yet, but I have to get me one of these.... I have almost been clobbered multiple times by my HiLift and I will lay it to rest as soon as a good alternate is released...

I have seen those jacks on a few sites on FB... such a simple idea and such a GREAT idea. Why didn't I think of that??

MountainD

Adventurer

Had a 98% great trip to Pawnee National Grasslands, but the wiffletree raising mechanism froze when we were putting it up. There was a strong side wind as you get in those areas, and the resulting pressure on the sides of the top when raising made the screw sort of cross thread and seize breaking the shear pins (and no longer run smooth). It got close enough to up when I stopped it and I got the door on and it was a great camping trip. But trying to get it down, it didn't go and actually spun the wires on the wiffletree and became quite a mess before shearing the pins off to stick open. One of the advantages of building the damn thing was I was able to get it down by taking all the cables off and lowering it with help of my wife. Got home safe and sound.

So I decided to redesign how I would make this darn thing raise. Looking at the cables, it appears that it pulls the cables approximately 17" to raise the top 51"--so it must go through a 3:1 mechansim in the arms. The top, knowing that I can put some crap on top of in the future can weight what? Say 300lbs. max. But you get friction too, so say 400lbs. You have a 3:1, so I need something that can lift 1200lbs 17" minimum. Fine. I decided on this beast: https://www.progressiveautomations.com/heavy-duty-linear-actuator PA-17 model with an 18" throw and 2000lb load and wet location, IP65 with a stainless steel body. It has built in adjustable limit switches too and is pretty darn quiet. It is huge but fits across the width of the trailer (by 2" open!).

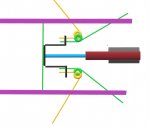

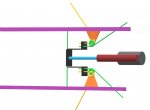

I have ripped out all the other mechanisms and am currently working on the mounts. It will mount to the trailer frame in back and then use a unistrut trolley wheel system on the sides for it's travel on the front. I have to make a U bracket which I am bending out of 1/4" steel in order to move the cable holder back to it's original position. Here is the basic layout along with the underside of the trailer with existing cable locations before I cut out all the cross members. The Green and Yellow donuts in the sketches are the pulleys that will be welded onto the unistrut braces. I am going to make the assembly as a tray that I will weld in as one piece. More on this as I start welding things up!

So I decided to redesign how I would make this darn thing raise. Looking at the cables, it appears that it pulls the cables approximately 17" to raise the top 51"--so it must go through a 3:1 mechansim in the arms. The top, knowing that I can put some crap on top of in the future can weight what? Say 300lbs. max. But you get friction too, so say 400lbs. You have a 3:1, so I need something that can lift 1200lbs 17" minimum. Fine. I decided on this beast: https://www.progressiveautomations.com/heavy-duty-linear-actuator PA-17 model with an 18" throw and 2000lb load and wet location, IP65 with a stainless steel body. It has built in adjustable limit switches too and is pretty darn quiet. It is huge but fits across the width of the trailer (by 2" open!).

I have ripped out all the other mechanisms and am currently working on the mounts. It will mount to the trailer frame in back and then use a unistrut trolley wheel system on the sides for it's travel on the front. I have to make a U bracket which I am bending out of 1/4" steel in order to move the cable holder back to it's original position. Here is the basic layout along with the underside of the trailer with existing cable locations before I cut out all the cross members. The Green and Yellow donuts in the sketches are the pulleys that will be welded onto the unistrut braces. I am going to make the assembly as a tray that I will weld in as one piece. More on this as I start welding things up!

Attachments

Last edited:

MountainD

Adventurer

Got everything installed and welded up. Works awesome--top goes up or down in under a minute, very quietly I might add, and the limit switches function to start/stop the mechanism. I have it on a momentary switch that I mentioned above (https://www.amazon.com/gp/product/B078RW9Q8Y/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 ) and it functions flawlessly. Not sure why all trailers don't utilize these! The original design had a "pulley block" so all four pulleys, corresponding to the four pop up cables/risers, was all one piece and it was able to basically cancel out the opposing forces of the front/back of the trailer cables. Since the actuator divides the pulleys into two pair (one pair for the front cables, one for the back), I did experience a little torquing of the unistrut so I had to put a cross brace above the actuator to counter act those forces. To attach the cables, I welded a cup that the end of the actuator goes into--I lathed out the inside to be a nice fit to the end of the actuator. The design worked out great--all that is left is rerouting the brake line and securing the electrical wires...