Ouiwee

Observer

Here is what the thermostatic valve looks like...it is large once you plumb it with -12 AN hose.

It resides on the passenger side radiator support.

From under the truck...

With stone guard/shield.

I guess I need less steering drop from the box...have attempted to keep the truck as low as possible. Maybe a 2" instead of 4" drop?

Anyway, I put in 3 quarts of oil expecting about 2 quarts additional oil required to fill the cooler and lines. I was close and had to remove roughly a quart once everything was hot.

I am tickled with the results. Of course, the electric fans are left undone but I don't anticipate too much trouble hooking up the controller. I have noticed that when everything is hot and ugly, the 600 rpm GM set for the engine isn't copacetic with the accessories I have bolted to the engine. There is a serious voltage drop with the big fan rolling and steering isn't super easy. I have tested and it seems 800 rpm is where we ought to be.

Good grief, I have 30 hours work in this cooler and I haven't missed a stitch.

And it has been hot here, 90+ degrees F. Good testing weather, I suppose.

It resides on the passenger side radiator support.

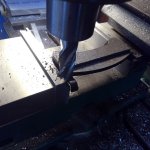

From under the truck...

With stone guard/shield.

I guess I need less steering drop from the box...have attempted to keep the truck as low as possible. Maybe a 2" instead of 4" drop?

Anyway, I put in 3 quarts of oil expecting about 2 quarts additional oil required to fill the cooler and lines. I was close and had to remove roughly a quart once everything was hot.

I am tickled with the results. Of course, the electric fans are left undone but I don't anticipate too much trouble hooking up the controller. I have noticed that when everything is hot and ugly, the 600 rpm GM set for the engine isn't copacetic with the accessories I have bolted to the engine. There is a serious voltage drop with the big fan rolling and steering isn't super easy. I have tested and it seems 800 rpm is where we ought to be.

Good grief, I have 30 hours work in this cooler and I haven't missed a stitch.

And it has been hot here, 90+ degrees F. Good testing weather, I suppose.