rayra

Expedition Leader

more follows

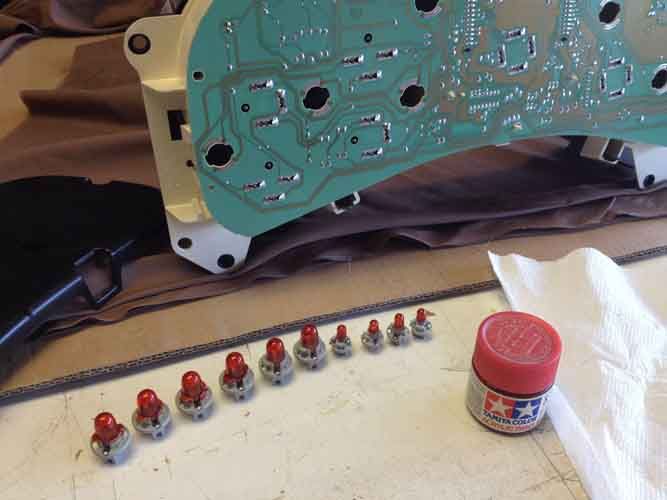

Here's a shot of Knock Sensor #1 (the front one), sitting in its sump. It's in 'okay' condition, a little shabby. I'll probably pull it when I re-open the engine, and try to rehab it some. Remove it and clean it up, naval jelly maybe.

Here's Knock Sensor #2, rusting in its hole. I think that fluid is gas, courtesy of lifting and tipping the intake manifold during its removal, gas dribbled out of the open fuel rails on it. I sopped it out with a towel after the pic, but my nose was full of gas and solvents / degreasers, so didn't really notice what it was. Didn't matter, at that point.

I've got a new knock sensor and a new wiring harness coming in the mail. In the meantime, the Sub is running ok. Actually didn't at first.

When I put it back together monday night (finishing about midnight), the idle was a little elevated. I sort of attributed that to the new intake manifold gasket and the computer learned settings being off. I didn't reset anything. Tuesday I ran some errands and it was idling very high and surging hard when I was off the gas and on the brakes and threw a Check Engine. Code was 'fast idle, more air than expected' or somesuch, didn't write it down. Looked things over for an open vacuum connection, sprayed some carb cleaner around the intake gasket plane, wondering if I'd screwed something up late last night. Didn't find anything

So googled around for fast and wandering idle symptoms in these vehicles / engines and found several references to the Idle Air Control (IAC) on the throttle body. When I'd worked on it monday I'd tried to clean up a bunch of filth. I had the throttle body off the intake manifold and was cleaning it out from both front and back. I'd sprayed some throttle body cleaner in some of its ports. One of those leads to the IAC. That port and a small hole in the throttle plate are the only air the engine gets at idle. The IAC is a solenoid-driven plunger that meters the air passing thru that port. Seems when I sprayed it, the fouling melted and glued the IAC in place, screwing up the mix and thus the idle speed. And preventing the IAC from functioning properly.

$80++ part. Hour plus and inconvenience of a mechanic visit. Or thanks to the internet, an easy 10min fix with $1 worth of spray.

Here's where I was mucking about

The IAC is bolted onto the right side of the throttle body ('00-'02 and maybe earlier), held on with (2) T20 screws. The lower is a little awkward to get to.

Here's what it looked like. Bad auto-focus, got the background. The surface of the thing looked 'hairy' like a magnetic drain plug. The sides of the plunger were caked. As was the 'blow by' area near the o-ring on the solenoid. A little scrubbing and wiping and poking around and some throttle body spray cleaned it right up.

During that evolution I had the battery disconnected, specifically to clear the learned settings out of the computer memory. Put it all together and its running properly. normal smooth idle, proper response etc.

now I'm just waiting to do it all over again when my knock sensor parts come. And then I'll also pull and replace those heater hose connections, too.

The whole 'remove intake manifold' is really a lot easier on these motors than on my old small block chevy. Things are better organized and arranged to make working on a subassembly much easier. Changing the intake manifold gaskets is listed as a 2.5hr evolution. This was my second time doing it (did our Tahoe several weeks ago) and I'd say I'd met that standard, if that was all I was doing. Once you are familiar with the layout, it's quite easy to make the necessary disconnections and take the whole thing off. The fiddly fuel injector electrical connectors are the toughest part.

Here's a shot of Knock Sensor #1 (the front one), sitting in its sump. It's in 'okay' condition, a little shabby. I'll probably pull it when I re-open the engine, and try to rehab it some. Remove it and clean it up, naval jelly maybe.

Here's Knock Sensor #2, rusting in its hole. I think that fluid is gas, courtesy of lifting and tipping the intake manifold during its removal, gas dribbled out of the open fuel rails on it. I sopped it out with a towel after the pic, but my nose was full of gas and solvents / degreasers, so didn't really notice what it was. Didn't matter, at that point.

I've got a new knock sensor and a new wiring harness coming in the mail. In the meantime, the Sub is running ok. Actually didn't at first.

When I put it back together monday night (finishing about midnight), the idle was a little elevated. I sort of attributed that to the new intake manifold gasket and the computer learned settings being off. I didn't reset anything. Tuesday I ran some errands and it was idling very high and surging hard when I was off the gas and on the brakes and threw a Check Engine. Code was 'fast idle, more air than expected' or somesuch, didn't write it down. Looked things over for an open vacuum connection, sprayed some carb cleaner around the intake gasket plane, wondering if I'd screwed something up late last night. Didn't find anything

So googled around for fast and wandering idle symptoms in these vehicles / engines and found several references to the Idle Air Control (IAC) on the throttle body. When I'd worked on it monday I'd tried to clean up a bunch of filth. I had the throttle body off the intake manifold and was cleaning it out from both front and back. I'd sprayed some throttle body cleaner in some of its ports. One of those leads to the IAC. That port and a small hole in the throttle plate are the only air the engine gets at idle. The IAC is a solenoid-driven plunger that meters the air passing thru that port. Seems when I sprayed it, the fouling melted and glued the IAC in place, screwing up the mix and thus the idle speed. And preventing the IAC from functioning properly.

$80++ part. Hour plus and inconvenience of a mechanic visit. Or thanks to the internet, an easy 10min fix with $1 worth of spray.

Here's where I was mucking about

The IAC is bolted onto the right side of the throttle body ('00-'02 and maybe earlier), held on with (2) T20 screws. The lower is a little awkward to get to.

Here's what it looked like. Bad auto-focus, got the background. The surface of the thing looked 'hairy' like a magnetic drain plug. The sides of the plunger were caked. As was the 'blow by' area near the o-ring on the solenoid. A little scrubbing and wiping and poking around and some throttle body spray cleaned it right up.

During that evolution I had the battery disconnected, specifically to clear the learned settings out of the computer memory. Put it all together and its running properly. normal smooth idle, proper response etc.

now I'm just waiting to do it all over again when my knock sensor parts come. And then I'll also pull and replace those heater hose connections, too.

The whole 'remove intake manifold' is really a lot easier on these motors than on my old small block chevy. Things are better organized and arranged to make working on a subassembly much easier. Changing the intake manifold gaskets is listed as a 2.5hr evolution. This was my second time doing it (did our Tahoe several weeks ago) and I'd say I'd met that standard, if that was all I was doing. Once you are familiar with the layout, it's quite easy to make the necessary disconnections and take the whole thing off. The fiddly fuel injector electrical connectors are the toughest part.

Last edited: