02SonoraZ71

New member

Hey all,

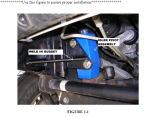

I changed my idler arm (moog k6534) and idler arm bracket (moog k6723) a while back and noticed that after the repair my center link was sitting about 1" higher on my passenger side than the driver's side, I belive there was a slight angle before but is seems to have increased after the repair. This resulted in a higher tie rod angle on my passenger side and on full turns to the right , my inner tie rod boot rubs on the sway bar. I wanted to see if you guys have had this same issue. Ive read on other forums of this happening on some trucks due to the known bumpsteer issue on these models. Below is a pic and if you compare the sway bar link on the bottom to the center link on top you can see how it is sitting higher on the idler (left) side. If any of you guys have pics for me to compare that would be great help.

Thanks,

Fred

I changed my idler arm (moog k6534) and idler arm bracket (moog k6723) a while back and noticed that after the repair my center link was sitting about 1" higher on my passenger side than the driver's side, I belive there was a slight angle before but is seems to have increased after the repair. This resulted in a higher tie rod angle on my passenger side and on full turns to the right , my inner tie rod boot rubs on the sway bar. I wanted to see if you guys have had this same issue. Ive read on other forums of this happening on some trucks due to the known bumpsteer issue on these models. Below is a pic and if you compare the sway bar link on the bottom to the center link on top you can see how it is sitting higher on the idler (left) side. If any of you guys have pics for me to compare that would be great help.

Thanks,

Fred