Backroadexploration

Observer

For those of you using a fridge slide in your Jeep. How did you secure it to the Jeep? I’m looking to add one to my setup and hoping to learn from your experiences!

This seems to be the most popular option I have seen. I am thinking of doing the same. I was hoping to find a way to just secure the slide to the factory mounting points, but I do not see an option. I have been doing some mockups to cut out some plywood. I was hoping to use another material that is lighter but everything else is much more expensive.I am planning for this as well, and so far it seems that there is a panel/floor attached to the four corner tie down points in the real floor that then allows you to attach the fridge slider to......I hope you followed that, i am two black-russians into Sunday night football.....

What type of slide are you planning to get? I ask because MORryde offers a no-drill bolt-in kit for the JK and JL for their Trail Kitchens.

The base Trail Kitchen provides a fridge slide plus a tray underneath for a two-burner stove and with the no-drill kit bolts in to the factory tie-down points. The base Trail Kitchen of course is more expensive than a simple slide (the ARB slide retails for a little under $400 and the base trail kitchen is about $550) but if you plan more than just a fridge it might be worth considering.

Do you have any pictures I would love to see it.For my JK, I built a full width sliding cargo tray that bolts to the rear seat mounts into the floor and the 4 tie down points on the floor. It is about 3-4” off the floor and allows access to the floor cubby and stores a folding plastic table underneath as well.

expeditionportal.com

expeditionportal.com

Hmmm... a generic no-drill fridge slide (and other gear) mounting kit - sounds like something that could be popular.This looks like a really slick option, however, it looks like more than I will have the space for. I wish they sold just the mounting crossbars that any slide system could tie into.

In my LJ I made a base plate out of 3/4” baltic birch plywood. The base plate is secured to numerous factory threaded inserts in the floor for the rear seat base, the seat belt anchors, etc.

View attachment 696191

The fridge slide is secured to the base plate with (6) 3/8” thread, pronged tee nuts. These tee nuts are epoxied into a shallow counter bore in the base plate.

View attachment 696192

You’re welcome.This looks like what I am thinking. If I can get mine to look half as good I will be pretty happy. Thanks for sharing!

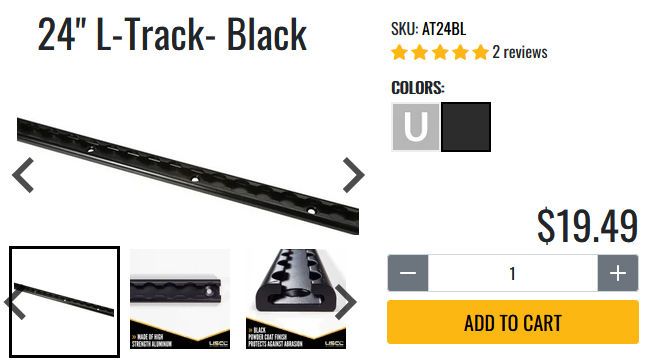

MOPAR offers what they call the "Trail Rail" option for securing things to the floor of the JL/JLU:Hmmm... a generic no-drill fridge slide (and other gear) mounting kit - sounds like something that could be popular.