Teardropper

Well-known member

I assume you'll join those with strips of carbon fiber cloth? And the final finish–UV clear coat, I assume?

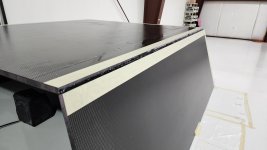

Great question really. The gap will be filled with Thixotropic epoxy that has been pigmented black. I have 3 inch tape for the purpose of covering the inside of the flange but I don't plan on using the tape at all. I know that will get many readers attention and perhaps in a skeptical way.I assume you'll join those with strips of carbon fiber cloth? And the final finish–UV clear coat, I assume?

Hardness | 85 ± 5 Shore D |

Tee-Peel Strength | 4 Lbs. per inch Width |

Compressive Strength | 15,800 psi @ 77°F (25ºC) |

Tensile Shear Strength | 3,700 psi @ 77°F (25ºC) |

| 2,200 psi @ -112°F (-80ºC) |

| 1,450 psi @ 212°F (100ºC) |

Elongation Maximum Yield | 2.3% |

Tensile Strength | 8,800 psi |

Service Temperature | -67°F to 250°F |

Thin Film Set Time | 120 minutes |

From the manufacture's website regarding Thixotropic and its mechanical properties.

It's quite OK Tony.Thanks. You obviously know what you're doing, so I'm leaving my skepticism in the closet.

Tony

Thanks a bunch for that page!Carbon: #5750 https://uscomposites.com/shortroll.html

You are quite welcome. Yeah, there are books written on how to best join corners and more or less they all work. The main thing to focus on is what works for you. If you have experienced Carbon Fiber cracking at levels higher than Fiberglass I would tend to say that every thing being equal you have been using the wrong resin. I have build many things over the last 40 years beginning with glass and the last 35 in Carbon and I have never seen any failures. That included 2 heavy adventure bike bash plates. It is so important to do a bit of testing with your epoxys and once you find a vendor that delivers a great product you really want to stick with it. I have been using Polymer Composites in Ontario for the past 24'ish years and I have never seen a failure. That includes several different types of polymers.Thanks a bunch for that page!I used the 11oz cloth at the bottom a few years ago, bought from another place. When they quit selling it, I couldn't find it anywhere. The price is higher at USC, but it's still a great price for carbon.

I'd also like to thank you for posting this! Great info on a useful subject.

Now, a few questions and comments about your build... now that you are almost finished...

I agree regarding the edges... we tend to worry about it way too much on this site! Some Australian manufacturers are getting away with joining panels by basically slapping PU adhesive in a butt joint. I did fill the joints, sand them, and layup at least a couple layers of thick cloth on the inner and outer edges... but it was probably major overkill... and a major mess!

About the adhesive, I don't know if there was something special in the type you used, but I just mixed fumed silica in with the epoxy to thicken it, and this worked well.

I'm envious of your nice finish. I did hand layup. With FG I had ~1 to 1 ratio of cloth and epoxy by weight, but 1 to 1.5 with carbon due to its lower density.

In my experiments, carbon does crack more readily than fiberglass (same thickness), in impact testing. Carbon is a little stronger and a little lighter, but the main thing it has vs FG is stiffness. It's about 3x stiffer in matrix... so if you need something to be stiff, carbon is best. FG is actually quite flexible for a structural material.

I did a lot of testing. I think I liked that more than actual building. I did not like the cheap XPS foam, as it is weak... rips apart if you try to pull off the skin, and has poor support for the skins on impact... and epoxy doesn't stick to it well. Sanding and texturing improve it, but I ended up using PVC foam from Carbon Core, which is in a completely different league. It's also more expensive... and price keeps going up, like everything I guess. 1/2" full sheets are $90 now, and the 1.5" inch I used are $250, plus freight. https://www.carbon-core.com/product/pvc-structural-foam-sheets/ XPS will likely be fine in your application, though.

We got to blow stuff apart.... Bwaaaamuuuuhahahahaha.

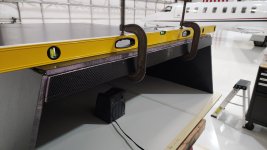

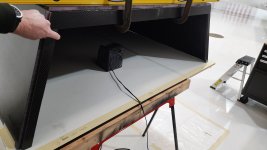

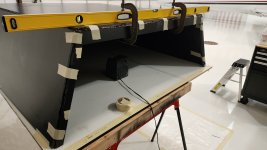

I bonded two pieces of the layup just like I did on the box. Then covered it with Thoxotropic. Essentially same joint as on the box. The piece is 1.5 wide but as the thixotropic hardened it sorta ran away and only covered half of the 1.5 inches or 3/4 inches in total. It had also only cured 24 hrs but needed 48 to achieve full strength. I must say that I was impressed in several ways. First how well it articulated through out the stress and how much it took to break the joint. Should I spoil it...... Or ya wanna watch..... well... ha ha... It took 8.5 Kilos and I had to swing it a bit dynamically so it was right about there. The arm attatched to the saw horse is 2 inches, and the arm protruding away is 4.5 inches. Ask away.

Very impressive indeed.....

Destructive testing is indeed fun. I find it interesting but not just for the purpose of reaching the breaking point, but very much so past its breaking point see what failed and how it failed. When I made my first bash plate many moons ago I used a small throw away piece, went to the wall (Lived in El Paso TX at the time) and shot at it with a 40. I off course knew that it would penetrate so i went through a couple of quart size zip lock bags full of water first. Besides being a hoot I learned a lot from that and it led me to add a few layers of K-39 in the matrix. Mad scientist stuff for sure. Were I to build a full size box I would make a bunch of 8x4 sheets from 1 inch NGX. 3 layers of Carbon on both inside and outside. Bond it with Thixotropic. I would properly cut a few angles rather than bond the same way I did here simply for the reason that it is a lot of Thixotropic to use filling that void but thats just me.I was whacking the panel with a sledge hammer to judge the "impact resistance"... obviously an extreme case! It made sense to me that carbon would be a bit lower due to its higher stiffness, and not much greater strength. A better comparison might have been to normalize weight, in which case I suspect the carbon would have won.

I didn't pursue the matter beyond that, but if I built a similar camper again I'd use carbon for the whole thing rather than just the base/floor and rear hatch/door. I ended up making a pivoting mechanism to allow for the truck frame's torsional flex, and with that (no need for camper flex), it's better to make the camper stiff. With your 1/2" panels and fully boxed truck frame the carbon would be optimal for sure.