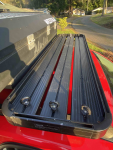

Therefore as I understand it on the Blue Sea instructions, I would want to hook the two power leads from the switch panel (the red wires sticking up in the picture below) to main positive terminal of the hub (since that is the hot wire coming direct from the battery). And then each switch on the panel would run to a + circuit on the hub, along with the positive wiring coming in from each "device" requiring power, which is where it get confusing since both would have to be wired into the same hook up. The negative from the device then would tie into the hub's negative common buss. Will this work?

I feel like I am maybe trying to combine the wrong two products, but just looking to see if I can make it work. I thought my hub would eliminate the need for the + or - Buss bars I see being used in the typical install, but maybe I still need one?? Any direction is appreciated.

View attachment 647619

Those are simple switches with just 2 terminals and the lever either makes or breaks the connection. They are no different than a valve on a water hose in that respect. This makes them very simple. It sounds like you desire to have 1 fuse for each switched circuit and will use your existing fuse panel for that.

Here is what you need to do:

Remove all those wires from the switches and throw them in your spare parts bin.

Use the "side" terminal (the ones that currently have positive wires on them) to connect each switch to 1 slot on your fuse panel. You will obviously need to assembly wires to do this with. Looks like spade lug (switch has male so wire needs female) on the switch end and ring terminals on the fuse panel end.

This will give you each switch fused independently which allows you to size the fuse for the device and wire the switch feeds. You will then connect to the wiring to each device from the end terminal on each switch using the same types of connectors as used on the side terminals they were fed fused power via.

The negative side for each circuit will go to the negative bus bar of the fuse panel.

Please let me know if you have any further questions on my description, hope it helps.