You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Isuzu npr 4wd

- Thread starter gator70

- Start date

SkiFreak

Crazy Person

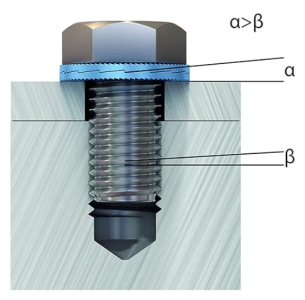

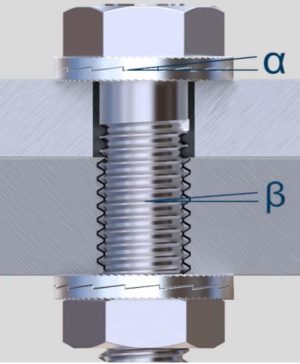

All methods that I know of for preventing the undoing of a fastener is done at the nut end.Can you confirm these are used under the bolt head, and not before the nut?

Obviously, if the fastener is only a bolt, you could not put the washers under the nut.

I have never used these washers on both sides of the fastener. I cannot see how that would be advantageous.

Where do you want to use NordLock washers in your build?

I can explain this later. My build has a different attachment to the habitat than most US builders.

My build has a subframe under the habitat floor. (the floor suspends 40 mm above the xps panel inside the living area) Then a mirror frame under the XPS panel floor (exposed below). A sandwich construction.

The complete habitat weights 1800 KG dry (about 4000lbs)

From that point the habitat is a unit. Now the spring suspended subframe made from 5 inch c-channel connects to the habitat unit and the truck frame.

I'm still at 11,600lbs dry weight complete.

The Australian design is made for a flatbed attachment like a slide in camper. My build is based on a European subframe.

This build below , although flatbed has a bolt through design with plates inside the living area.

Last edited:

mog

Kodiak Buckaroo

Ferjablito

Active member

Puedo explicarlo más tarde. Mi construcción tiene un apego al hábitat diferente al de la mayoría de los constructores estadounidenses.

Mi construcción tiene una subestructura debajo del suelo del habitáculo (el suelo cuelga 40 mm por encima del panel XPS dentro de la sala de estar). Luego, un marco de espejo debajo del suelo del panel XPS (expuesto abajo). Una construcción tipo sándwich.

El hábitat completo pesa 1800 kg en seco (aproximadamente 4000 libras).

A partir de ese momento, el hábitat se convierte en una unidad. Ahora, el subchasis con suspensión de resorte, fabricado con un canal en C de 5 pulgadas, se conecta al hábitat y al chasis del camión.

Todavía estoy en 11.600 libras de peso seco completo.

El diseño australiano está pensado para una plataforma plana, como una caravana deslizable. Mi diseño se basa en un subchasis europeo.

Esta construcción a continuación, aunque es de plataforma plana, tiene un diseño con pernos pasantes con placas dentro del área de estar.

View attachment 909063

Keep an eye on your weight, because if you're not careful, you'll be over the maximum allowed weight.

SkiFreak

Crazy Person

You are absolutely correct, and there are castellated nuts and split pins too, but I was referring more towards non mechanical methods, like lock washers and lock nuts.You can used safety wire

Out of those, the NordLock washers are one of the best at resisting continued, major vibration scenarios.

I have worked with a few people who own race cars and tie wire is used extensively in them, but tie wire is not the right option in every scenario.

There are a multitude of options when it comes to stopping nuts and bolts from working themselves loose. The skill is in using the most appropriate option for a specific situation.

mog

Kodiak Buckaroo

All methods that I know of for preventing the undoing of a fastener is done at the nut end.

Safety wiring is done when there is not a 'nut end'. If there is a 'nut', that is the preferred end of the fastener.You are absolutely correct, and there are castellated nuts and split pins too, but I was referring more towards non mechanical methods, like lock washers and lock nuts.

Out of those, the NordLock washers are one of the best at resisting continued, major vibration scenario

There are also locking tabs, but those are usually specific to an application.

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 7

- Views

- 1K

- Replies

- 28

- Views

- 3K