Stoffregen Motorsports

Explorer

This Cherokee sat for so long that literally every mechanical and electronic part needed to be rebuilt or replaced. Funny how people think letting a vehicle sit is actually a good thing. Nope... The only thing I did not have to replace or rebuild in the engine bay was the spark controller. The brake booster seems to be holding, but I bought a new one just in case (haven't installed it yet). Mecahincally speaking, everything else in the engine bay had to be rebuilt or replaced. As far as the rest of the Cherokee was concerned, anything that moved at some point was frozen up.

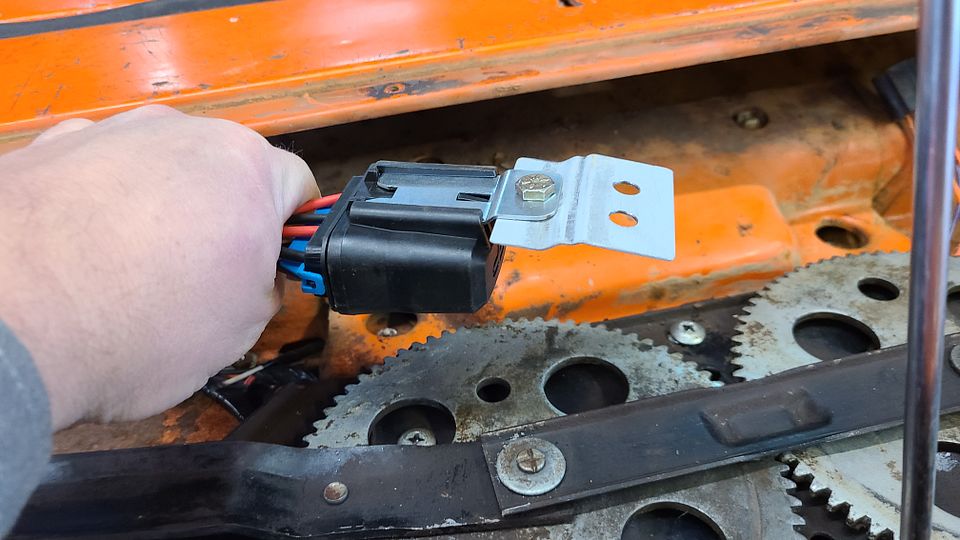

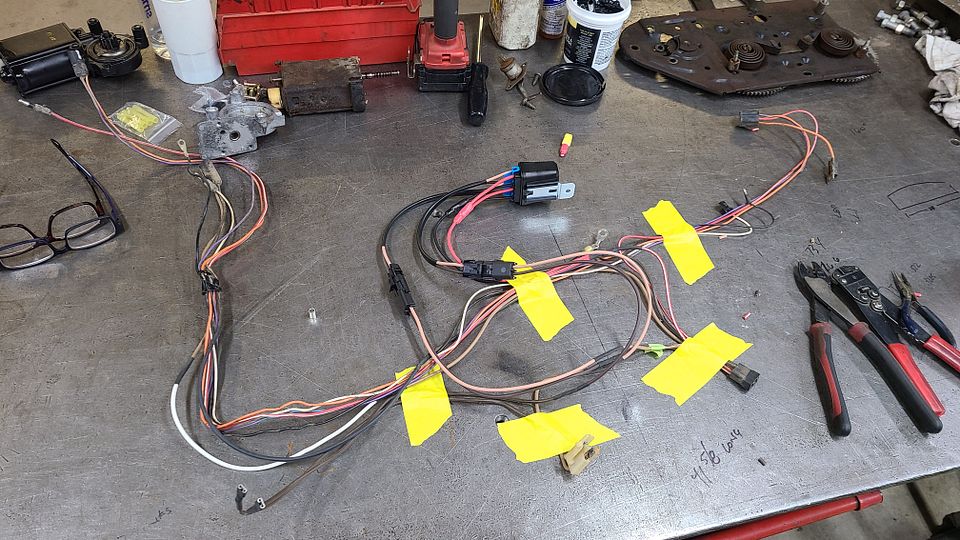

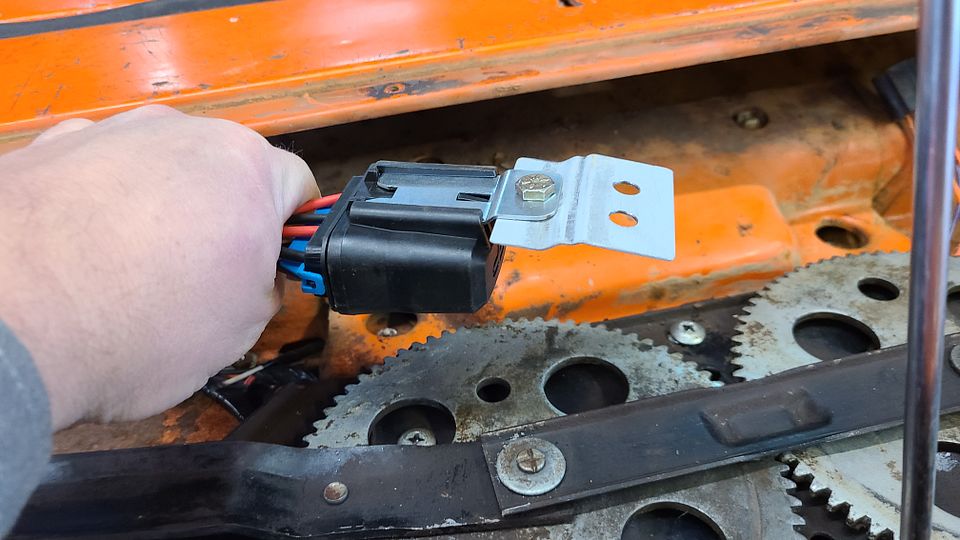

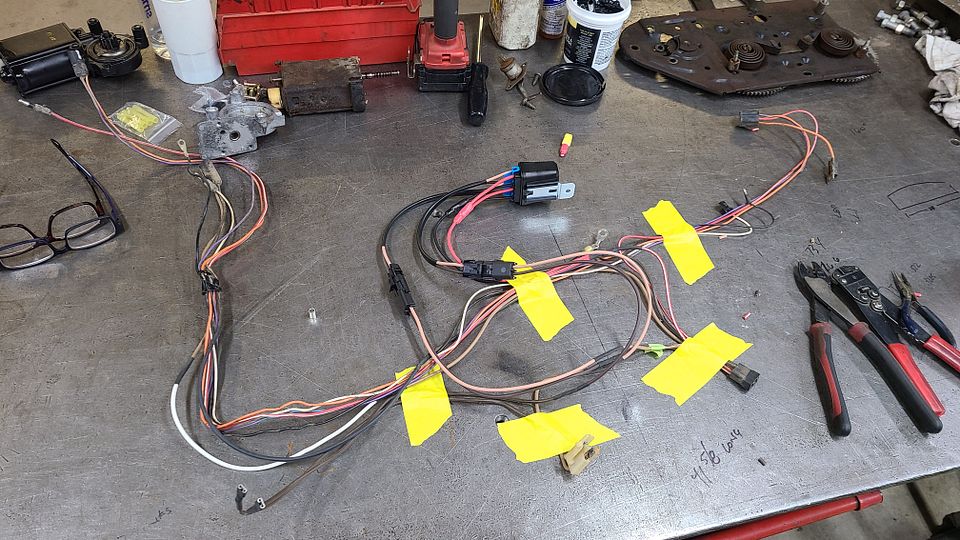

One of the items on the list was the rear window electric motor. It was actually rusted through and the window was stuck, luckily, in the down position. Finding a new motor proved to be difficult, as everyone that listed it was out of stock. Not deterred, I scoured the web for on that looked similar and found one from a classic Buick that looked the same. When I received it and opened the box, it was nearly identical except for two minor differences. Fisrt and most obvious was the body length, which was about half an inch shorter. Second and not immediately obvious was the length of the three legs that mount it to the window regulator assembly. My first thought was to use the motor portion of the new unit and attach it to the gear portion of the Jeep motor. I fiddled with this for hours and couldn't get the motor to work consistently, so I gave up. Then I tried rebuilding the rusted out Jeep motor, and I was able to get it to work, but again, consistency was the issue. Ultimately, what I ended up doing was to machine the three mounting legs on the Buick motor to make them shorter, and it worked like a charm. Sure, I lost the small register from each leg (which locates the motor in the regulator, but so far, this hasn't been a problem. One side benefit to using the shorter Buick motor was that the original motor was so long that the connector housing was contacting the body. The new motor, being shorter, allowed for a bit of wiggle room. And while I was in there, I installed a heavy duty relay kit from BJ's to help bring the motor up and down a little faster, and safer. I also rewired the entire tailgate. What a pain in the ass that was... The hole where the harness fits into the main body it super tight. It took a solid hour to get the wiring through the two holes and securely protected with wire loom.

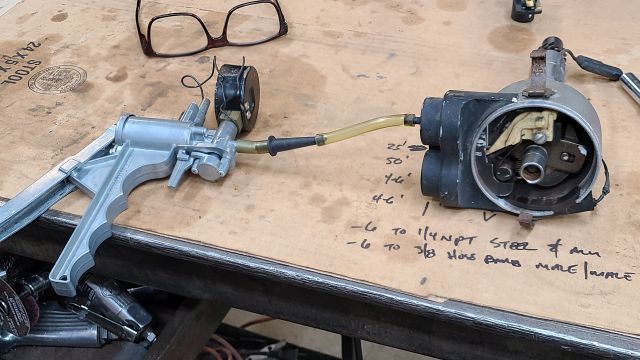

Another item that needed attention was the power steering. Even with the pump cleaned out and verified for flow, the box apparently gave up the ghost and would not accept the hydraulic fluid. Red Head Steering Gears is my go-to for steering box rebuilding, and I had a new one in a day. New hoses, new pump, new box. Everything there now works like it should. I even rebuild the shaft between the column and box and installed a new rag joint.

One of the items on the list was the rear window electric motor. It was actually rusted through and the window was stuck, luckily, in the down position. Finding a new motor proved to be difficult, as everyone that listed it was out of stock. Not deterred, I scoured the web for on that looked similar and found one from a classic Buick that looked the same. When I received it and opened the box, it was nearly identical except for two minor differences. Fisrt and most obvious was the body length, which was about half an inch shorter. Second and not immediately obvious was the length of the three legs that mount it to the window regulator assembly. My first thought was to use the motor portion of the new unit and attach it to the gear portion of the Jeep motor. I fiddled with this for hours and couldn't get the motor to work consistently, so I gave up. Then I tried rebuilding the rusted out Jeep motor, and I was able to get it to work, but again, consistency was the issue. Ultimately, what I ended up doing was to machine the three mounting legs on the Buick motor to make them shorter, and it worked like a charm. Sure, I lost the small register from each leg (which locates the motor in the regulator, but so far, this hasn't been a problem. One side benefit to using the shorter Buick motor was that the original motor was so long that the connector housing was contacting the body. The new motor, being shorter, allowed for a bit of wiggle room. And while I was in there, I installed a heavy duty relay kit from BJ's to help bring the motor up and down a little faster, and safer. I also rewired the entire tailgate. What a pain in the ass that was... The hole where the harness fits into the main body it super tight. It took a solid hour to get the wiring through the two holes and securely protected with wire loom.

Another item that needed attention was the power steering. Even with the pump cleaned out and verified for flow, the box apparently gave up the ghost and would not accept the hydraulic fluid. Red Head Steering Gears is my go-to for steering box rebuilding, and I had a new one in a day. New hoses, new pump, new box. Everything there now works like it should. I even rebuild the shaft between the column and box and installed a new rag joint.

.jpg?width=960&height=720&fit=bounds)

.jpg?width=960&height=720&fit=bounds)