Great. I love when you guys ask for updates. It makes me feel like the time spent compiling pics is not wasted.

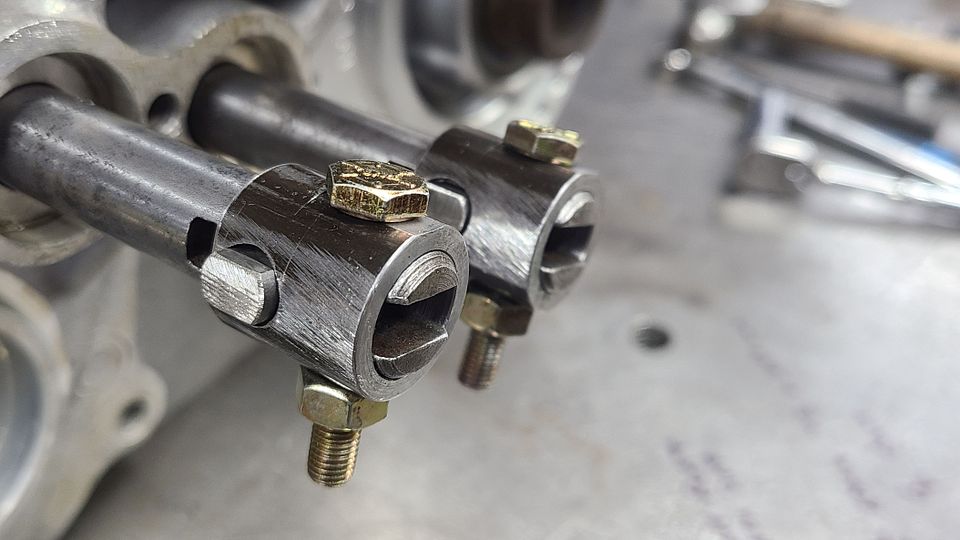

Here's a bit of an update. All of the sheetmetal work has been completed, and the body is now back at American Stripping for a final white metal blast and powder coating. The powder is a zinc rich material which will act as the primer, but is also better because it's baked on. Getting it ready for blasting and coating took a long time. Obviously the metal work had to be completed beforehand, but a thorough mock up and more seemingly unrelated fabrication needed to be done to make sure I didn't have to drill or cut holes once the body came back from the paint shop. All of the holes were cut/drilled in the firewall for wiring and plumbing. The transmission and t-case got new, custom shifters which clear the dash and passenger seat (you'll see what I mean in a minute). The air box and intake tube were built along with the power distribution and fuse box brackets and all associated holes were drilled and tabs welded.

Then came final body fit. I mocked up the front clip to get ready for adding the Jeepster eyebrows to the CJ7 grille shell, and while I was there, I found some surprises. The hood had been smashed and repaired at some point, probably decades ago because the paint looked original, which meant that the fit to the grille was horrible. So that had to be repaired. The fenders needed some work too. Filling holes and welding cracks mostly. The once the front end was finished and ready to go, focus was turned to the remaining body panels- the doors, windshield frame and tailgate. The doors were in great shape, aside from a bad repair done years ago to "fix" a torn out window guide hole, but when I got to the tailgate, I was shocked to find that the entire bottom of the tailgate was rotted, and again, the repair looked good at a glance. I figured the tailgate would have been the easiest prep for paint, but after 10 hours or metal replacement, I was proven wrong.

Pics are being compiled on Photobucket as we speak, so give me a few minutes and you'll start seeing some pics.