Stoffregen Motorsports

Explorer

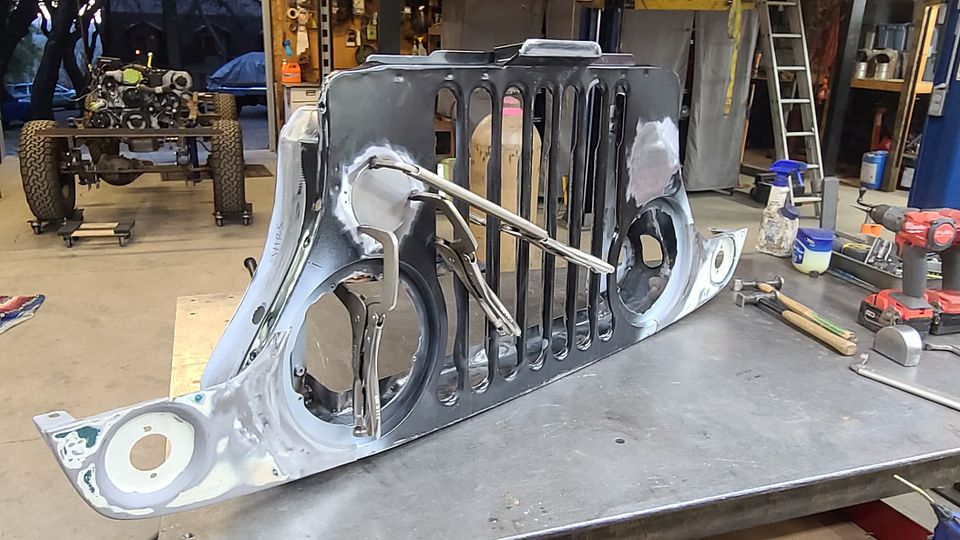

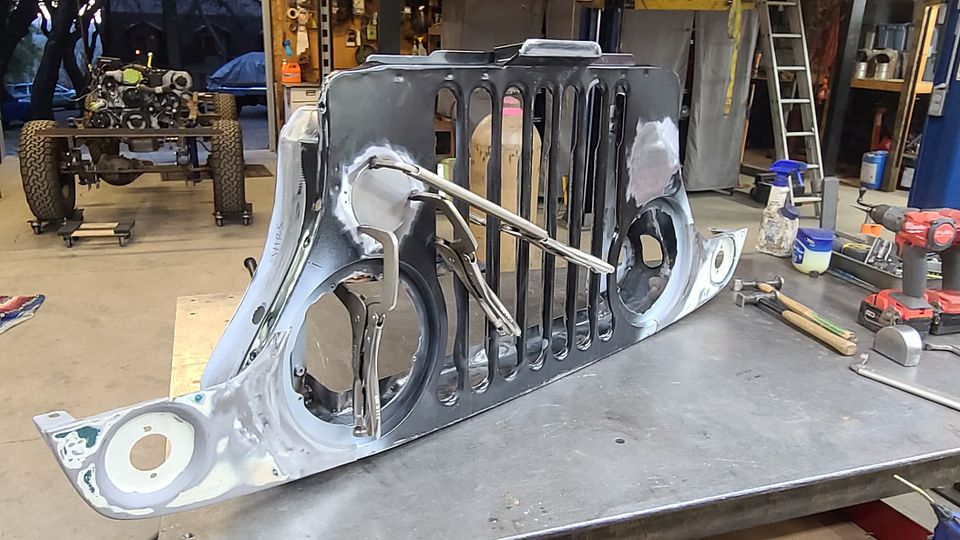

Once the mechanical portion was completed, ie- intake and such, the body came off to be able to access the interior of the engine bay. At this point, the CJ7 grille took delivery of the Jeepster eyebrows. Even those had to be modified in the name of proper panel fitment.

And since I couldn't find a suitable pair of round LED fog lamps to fit the CJ7 turn signal holes, those were filled too.

And since I couldn't find a suitable pair of round LED fog lamps to fit the CJ7 turn signal holes, those were filled too.