Plastics are weak, flexible, creep, and change dimensions a lot when temperature changes.

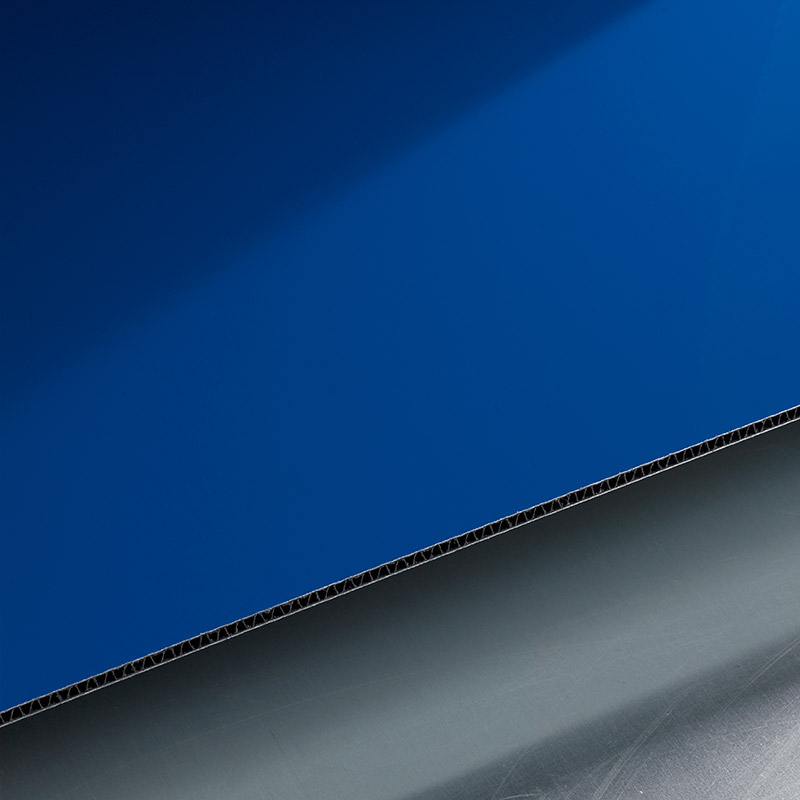

I've made composite panels (hand layup) using foamed PVC signboard as a core. Fiberglass works well and takes care of all the issues above, but it's not all that stiff either. Carbon is very stiff, but takes impact less well than fiberglass.

as "plastics" go, that may be, but I believe the sign boards have PVC, I have 2 4x8 sheets and some smaller pieces and mounted to a wood frame I've not found those issues with it.

A place here uses a 4x8 sheet in a metal frame, I know it's been there for just over 9 years now and it looks the same as it did when it was put up. I would have thought that the UV would have turned the white board into dingy tan by now, but it has held up well and kept the white color, it faces to the West.

There's a guy on Youtube that made cabinets out of insulation board, blue board, then covered with glue and cloth, poor man's fiberglass, after paint they looked pretty good, but can't tell from the video.

I believe on TT&T a guy built a teardrop out of the duraplast and covered it in vinal, looked good. I've found that this stuff is pretty tuff, but framing should be about 12 inches, much closer than 16/18/24 inches on wall construction. For a camper I don't know if the additional framing would exceed the weight savings from foam core but the price would be much less.

Same with a cabinet, depending what goes in it, framing at 12 inches would be fine for most stuff, clothes, shoes/boots/ food and light cooking ware, but I don't think it would work well holding a few cases of full cases of beer.

If I ever put a bathroom in the front of my cargo trailer that D-P will make a good interior wall and shower enclosure, it would just be a screen.

Don't know what you have in mind for cabinets, I thought about cabinets and trying to save weight, what ever they are usually made is too heavy for my needs. Which made me decide to go with wire shelves that are in my walk-in closet, then use bags.

I don't know the brand of off road trailer, but I noticed a bag system was used on the walls instead of cabinets or cubby holes and that trailer was one of the expensive ones.

Bags don't weigh hardly anything, can hold a lot and carry weight, when not in use they save space, unlike box cabinets.

Post up your solution for cabinets.