Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lower ball joint cheat 94 SR?

- Thread starter 94monster

- Start date

Justice R

Adventurer

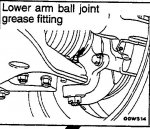

Be sure you grease your steering stops to before you pull the LBJ. New from the factory they have a rubbery plasic covering which wears off. When you compress the suspension at full lock you get a "horrible noise" from metal on metal contact. Grease remedies this.

If you you still need to replace you should be able to pull it by disconnecting the LBJ from the knuckle first then unbolting it from the lower A-arm. Beware the lower a arm is under spring pressure from the torsion bar. You might want to unwind them. I've done it without unwinding, but you need to be aware.

If you you still need to replace you should be able to pull it by disconnecting the LBJ from the knuckle first then unbolting it from the lower A-arm. Beware the lower a arm is under spring pressure from the torsion bar. You might want to unwind them. I've done it without unwinding, but you need to be aware.

off-roader

Expedition Leader

off-roader

Expedition Leader

Sorry I haven't had to (fortunately).

ca18_sean

Adventurer

Subscribed, I just bought all 4 ball joints from Moog and would like to see if anyone has any installation tips as well. Are there any write ups on ball joint replacement? Either on here or on the 4x4wire site...

I found this write up (actually done by the previous owner of my truck) on replacing an inner CV boot.

http://www.4x4wire.com/mitsubishi/tech/inner_cv/

It covers ball joint removal, but he was pulling the axle to R&R it, so I'm not sure if that was a requirement, or just something he was already doing.

I found this write up (actually done by the previous owner of my truck) on replacing an inner CV boot.

http://www.4x4wire.com/mitsubishi/tech/inner_cv/

It covers ball joint removal, but he was pulling the axle to R&R it, so I'm not sure if that was a requirement, or just something he was already doing.

off-roader

Expedition Leader

Didn't realize you bought Alex' Montero.

I'm pretty confident the FSM would also have a how to on removing the lower ball joint. Have you guys checked for it?

I'm pretty confident the FSM would also have a how to on removing the lower ball joint. Have you guys checked for it?

ca18_sean

Adventurer

Yep, had it shipped to Florida! I love it so far!

And I already read the FSM. It says to pull the axle and basically follow Alex's write up. Just wondering if there were any tricks that someone found out to make it easier. Doesn't look overly complicated, but any little trick helps

And I already read the FSM. It says to pull the axle and basically follow Alex's write up. Just wondering if there were any tricks that someone found out to make it easier. Doesn't look overly complicated, but any little trick helps

Similar threads

- Replies

- 9

- Views

- 1K

- Replies

- 8

- Views

- 3K