Lowly Truck Update!

Its been awhile and while not much has been happening on the truck, I have been taking some baby steps toward paving the way for a full blown conversion.

The biggest piece of news is that Harbor Freight (a cheap tool retailer) has opened up in my town since the arrival of Lowly. While some tool snobs and/or patriotic types might scoff at the thought of purchasing tools fresh off the boat from Red China, I don't harbor (pun intended) those same reservations for two reasons:

1) I'm thrifty

2) The tools I am willing to purchase there are good enough to complete the light-duty and infrequent tasks I'll be using them for

All that preface for the introduction of my most recent purchases from HF:

12-ton jack stands and a 20-ton bottle jack

While the truck currently weighs in between 9 & 10 tons, I went with the 12 ton stands due to their height, capacity and stable footprint. The bottle jack is beyond overkill but provides the height and extension I need for $10 more than the shorter 10-ton version.

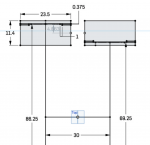

These will be put to use in elevating the truck with the intent of removing the wheels/tires so I can measure the face-to-face distance between the wheel mount flanges. All of this to figure out how to get Lowly a set of rims that will achieve the following:

1) convert him to larger diameter single tires in front and rear (rear are currently dualies)

2) align front and rear single tires so they track with each other

3) utilize the same rim/tire combo on all 4 corners of the truck (rim/flange will have the same offset for both front and rear)

4) make rims 2-piece with bolt-together flange & o-ring similar to military type setups

All of this will likely be exceedingly difficult and frustrating to accomplish but if I succeed, the finished product should be worthwhile. Stay tuned.

- Sheik

NOTE: 12-ton stands were exchanged for 6-ton as the 12-ton were too tall for the rear axle. A classic example of convenience winning out over confidence/safety!