Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lowly the Lorry. . .

- Thread starter jaleel_da_sheik

- Start date

jaleel_da_sheik

Observer

Lowly Update:

Time runs short for getting the truck road worthy once more in order to cannonball up the the US/Canada border for permanent importation purposes. I've been focusing on tidying up the hydraulics while noodling on the electrics and pneumatics.

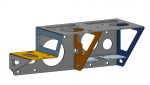

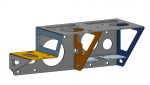

The control valves for operating the winch and drop-down arms at the rear of the truck were originally hung off the underside of the box's structural framing. With the box removed a new mounting scheme was needed. After some careful measuring of the valve's mounting geometry and available space along with much thought to future subframe and habitat box geometry, I CAD modeled up a new mounting bracket:

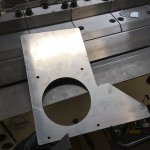

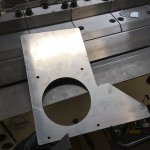

A great fabrication shop I use for both my engineering/product development business and my rafting equipment business cut the parts on their plasma table. Big thanks to the guys at Rogue Gear Works in Merlin, Oregon!

With parts prepped it was time to tack the weldment together:

A test fit of the valving was conducted to make sure I didn't forget any critical dimensions while trying to shoe-horn all these pieces into a small volume:

Everything appeared to fit with hopefully enough wrench clearances to reattach all of the hydraulic lines. Last step was to weld it up solid and grind down all the ugly welds. Thankfully this will live its life out of sight and my welding abilities won't be on full display. Plan is to get it mounted up in a few days and tackle the spaghetti-mess of hydraulic lines next week.

Stay tuned,

- Sheik

Time runs short for getting the truck road worthy once more in order to cannonball up the the US/Canada border for permanent importation purposes. I've been focusing on tidying up the hydraulics while noodling on the electrics and pneumatics.

The control valves for operating the winch and drop-down arms at the rear of the truck were originally hung off the underside of the box's structural framing. With the box removed a new mounting scheme was needed. After some careful measuring of the valve's mounting geometry and available space along with much thought to future subframe and habitat box geometry, I CAD modeled up a new mounting bracket:

A great fabrication shop I use for both my engineering/product development business and my rafting equipment business cut the parts on their plasma table. Big thanks to the guys at Rogue Gear Works in Merlin, Oregon!

With parts prepped it was time to tack the weldment together:

A test fit of the valving was conducted to make sure I didn't forget any critical dimensions while trying to shoe-horn all these pieces into a small volume:

Everything appeared to fit with hopefully enough wrench clearances to reattach all of the hydraulic lines. Last step was to weld it up solid and grind down all the ugly welds. Thankfully this will live its life out of sight and my welding abilities won't be on full display. Plan is to get it mounted up in a few days and tackle the spaghetti-mess of hydraulic lines next week.

Stay tuned,

- Sheik

Last edited:

jaleel_da_sheik

Observer

Lowly Update:

In the process of removing the back of the truck, I eliminated a large portion of the hydraulic systems (generator & Jaws-of-Life ports). In doing so I was able to delete a large hydraulic manifold that fed these components from the PTO driven hydraulic pump. Upon investigation, this pump is a "multi-flow" style pump which split the outgoing flow into two separate circuits for just this sort of situation. Now that 1/2 of the hydraulic components on the truck have been removed along with their manifold, I no longer need for a split flow output, nor do I want one. In order to simplify the hydraulic circuit for the remaining components (winch & drop-down arms) I had to modify the outflow fittings to merge the 2 outflows into a single line with the intent of capping the second. Had I just capped one of the lines without merging the streams, damage to the pump would have resulted.

After doing some flow area calculations I drilled an appropriately sized hole through the tube's walls to allow the banjo fitting's (rectangular block) flow to enter the flow within the tube.

Here is a hand-held mockup of the modified components where they mount to the outflow end of the pump.

Upon complete re-assembly, I'll cap off the flow that once exited the banjo fitting. I could have just T'ed one outflow into the other outflow line and not modified the components but wanted the simplified circuit with no additional hydraulic lines.

- Shiek

In the process of removing the back of the truck, I eliminated a large portion of the hydraulic systems (generator & Jaws-of-Life ports). In doing so I was able to delete a large hydraulic manifold that fed these components from the PTO driven hydraulic pump. Upon investigation, this pump is a "multi-flow" style pump which split the outgoing flow into two separate circuits for just this sort of situation. Now that 1/2 of the hydraulic components on the truck have been removed along with their manifold, I no longer need for a split flow output, nor do I want one. In order to simplify the hydraulic circuit for the remaining components (winch & drop-down arms) I had to modify the outflow fittings to merge the 2 outflows into a single line with the intent of capping the second. Had I just capped one of the lines without merging the streams, damage to the pump would have resulted.

After doing some flow area calculations I drilled an appropriately sized hole through the tube's walls to allow the banjo fitting's (rectangular block) flow to enter the flow within the tube.

Here is a hand-held mockup of the modified components where they mount to the outflow end of the pump.

Upon complete re-assembly, I'll cap off the flow that once exited the banjo fitting. I could have just T'ed one outflow into the other outflow line and not modified the components but wanted the simplified circuit with no additional hydraulic lines.

- Shiek

Last edited:

jaleel_da_sheik

Observer

CRY FOR HELP!

Calling any owners of Mercedes-Benz trucks of the same type and vintage as Lowly. I have yet to source a maintenance manual for my truck and need some critical information:

Type and quantity of the following:

Engine oil

Transmission fluid

Power steering fluid

If you know where I can get my hands on one of these maintenance manuals please let me know. I've got a scanned service manual (partial, not entire) from the fire department who previously owned Lowly so I can read how to disassemble my engine and grind the valves but have no idea how much or what the of engine oil my truck needs!

- Sheik

Calling any owners of Mercedes-Benz trucks of the same type and vintage as Lowly. I have yet to source a maintenance manual for my truck and need some critical information:

Type and quantity of the following:

Engine oil

Transmission fluid

Power steering fluid

If you know where I can get my hands on one of these maintenance manuals please let me know. I've got a scanned service manual (partial, not entire) from the fire department who previously owned Lowly so I can read how to disassemble my engine and grind the valves but have no idea how much or what the of engine oil my truck needs!

- Sheik

DirtWhiskey

Western Dirt Rat

Can you repost the model, engine and tranny? I have some mad ninja research skills. And I like big Lowly.

VerMonsterRV

Gotta Be Nuts

If you have not already you should get the EPC/WIS manual for these trucks. I got is as a download and installed it on my Windows PC. If you search on Ebay you will find it. The WIS portion (Workshop Manual) has all this info. The EPC (parts manual) will have all part numbers for your specific truck (you enter the VIN). If I remember it was less than $20.CRY FOR HELP!

Calling any owners of Mercedes-Benz trucks of the same type and vintage as Lowly. I have yet to source a maintenance manual for my truck and need some critical information:

Type and quantity of the following:

Engine oil

Transmission fluid

Power steering fluid

If you know where I can get my hands on one of these maintenance manuals please let me know. I've got a scanned service manual (partial, not entire) from the fire department who previously owned Lowly so I can read how to disassemble my engine and grind the valves but have no idea how much or what the of engine oil my truck needs!

- Sheik

jaleel_da_sheik

Observer

HELP UPDATE:

Thanks for the info so far. I have purchased a EPC/WIS manual off of eBay but it isn't playing nice with my mac. I've got a request for assistance submitted to the seller but have yet to hear back. Being unable to run the VIN I don't have much in the way of details. Here's what I've got from the limited paperwork that accompanied the truck:

Mercedes 1120 4x4 Fire Engine

5958cc cylinder capacity

VIN: WDB6771832k089924

That's about it!

- Sheik

Thanks for the info so far. I have purchased a EPC/WIS manual off of eBay but it isn't playing nice with my mac. I've got a request for assistance submitted to the seller but have yet to hear back. Being unable to run the VIN I don't have much in the way of details. Here's what I've got from the limited paperwork that accompanied the truck:

Mercedes 1120 4x4 Fire Engine

5958cc cylinder capacity

VIN: WDB6771832k089924

That's about it!

- Sheik

Sitec

Adventurer

I have purchased a EPC/WIS manual off of eBay but it isn't playing nice with my mac. I've got a request for assistance submitted to the seller but have yet to hear back.

I did the same. It didn't work and needed all sorts of stuff uploading to make it work... I then spoke to the I.T guru at work, he had a quick look and said 'get rid quickly'... I did. The Ebay system involves a 'virtual computer' running on your computer, fooling the program into thinking its on a remote workshop computer somewhere else... Well, that's how it was described to me. However, a friend sent me a link to one that seems to work on our truck... You might be able to work back from ours and select your truck, so I'll PM that to you.

jaleel_da_sheik

Observer

HELP UPDATE:

Using Sitec's recommendation of a very helpful online MB manual I was able to plug in my VIN and get some useful info out:

TYPE - 1120AF

ENGINE - OM366LA 177kW/240HP (356.989)

OIL FILTER - A3661800809

AUTOMATIC TRANSMISSION - 720.099

POWER STEERING - LS3E (765.605)

Any ideas on how I can take this info and find out what type and what quantity of engine oil, steering oil and transmission oil?

- Sheik

Using Sitec's recommendation of a very helpful online MB manual I was able to plug in my VIN and get some useful info out:

TYPE - 1120AF

ENGINE - OM366LA 177kW/240HP (356.989)

OIL FILTER - A3661800809

AUTOMATIC TRANSMISSION - 720.099

POWER STEERING - LS3E (765.605)

Any ideas on how I can take this info and find out what type and what quantity of engine oil, steering oil and transmission oil?

- Sheik

VerMonsterRV

Gotta Be Nuts

You know, it might make sense to buy a used windows laptop for use in the shop. Then you wouldn't have to worry about getting a nice laptop grungy while working on the truck. There is a lot of info in the WIS, like torque settings for various bolts. I end up printing the pages out to save my laptop.HELP UPDATE:

Using Sitec's recommendation of a very helpful online MB manual I was able to plug in my VIN and get some useful info out:

TYPE - 1120AF

ENGINE - OM366LA 177kW/240HP (356.989)

OIL FILTER - A3661800809

AUTOMATIC TRANSMISSION - 720.099

POWER STEERING - LS3E (765.605)

Any ideas on how I can take this info and find out what type and what quantity of engine oil, steering oil and transmission oil?

- Sheik

jaleel_da_sheik

Observer

HELP UPDATE:

Thank you everyone for your feedback. With all of the information provided I'm on the hunt for the appropriate fluids that Lowly will appreciate!

I'll post an update once I get the fluids as a reminder for future reference.

- Sheik

Thank you everyone for your feedback. With all of the information provided I'm on the hunt for the appropriate fluids that Lowly will appreciate!

I'll post an update once I get the fluids as a reminder for future reference.

- Sheik

jaleel_da_sheik

Observer

Lowly Update:

Doing the hurry-up shuffle in order to get Lowly up to the Canadian border for permanent import purposes; need to leave in the next day or so!

First was mounting the hydraulic valve bracket to the chassis.

The valves were then bolted up to the bracket before re-attaching the existing hydraulic lines, electrical connectors and single pneumatic line.

Due to the relocation and reorientation of the valves all of these lines need to be shortened at some point in the future.

- Sheik

Doing the hurry-up shuffle in order to get Lowly up to the Canadian border for permanent import purposes; need to leave in the next day or so!

First was mounting the hydraulic valve bracket to the chassis.

The valves were then bolted up to the bracket before re-attaching the existing hydraulic lines, electrical connectors and single pneumatic line.

Due to the relocation and reorientation of the valves all of these lines need to be shortened at some point in the future.

- Sheik

Last edited:

Similar threads

- Replies

- 0

- Views

- 443

- Replies

- 2

- Views

- 234

- Replies

- 2

- Views

- 488

- Replies

- 16

- Views

- 4K