jaleel_da_sheik

Observer

Lowly Update:

Leaf spring work commences. Jacked the rear of the truck up and set the chassis on jack stands. Removed the dualies on each side and then used the jack to lift the left side of the rear axle until the leaf stack was neutral. Then the fun began.

For those of you just tuning in, Lowly lived his life as a work-a-day emergency response truck on the salty coastline of Wales. As a result of his youth his undercarriage is rusty wherever there isn't MB factory paint. This includes the threads on the massive U-bolts that hold the leaf stacks to the axle. I labored for an embarrassing amount of time using penetrating oil, wire brush, hammer driver, breaker bar, 4' cheater bar etc. with very little to show for it; headway on removing the nuts was painstakingly slow. Then the "little grey cells" (as Hercule Poirot would say) began to come alive and I realized I could just cut these U-bolts off because I just sold my firstborn for a set of new ones! Enter my Milwaukee angle grinder and cutoff wheel. Wam, bam, thank you ma'am.

After that it was a matter of pounding the leaf stack with a mini sledge until the rust broke loose in order to remove one leaf at a time.

With the leaf stack removed I was able to get a better look at what I'm calling the rear "sway bar" and its drop down brackets. The brackets are beyond leperous with rust to the point where replacement is necessary.

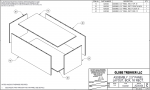

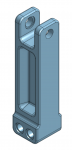

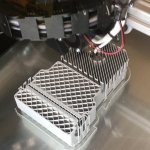

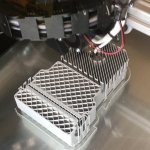

I've modeled up the bracket and am currently in the process of doing a proof-of-fitment test print on my 3D printer to see if I might be able to replace these brackets with carbon fiber/nylon 3D printed pieces rather than purchasing new ones or getting a new set fabricated.

So far I don't think I've ruined the truck and it actually feels like I'm making headway.

- Sheik

Leaf spring work commences. Jacked the rear of the truck up and set the chassis on jack stands. Removed the dualies on each side and then used the jack to lift the left side of the rear axle until the leaf stack was neutral. Then the fun began.

For those of you just tuning in, Lowly lived his life as a work-a-day emergency response truck on the salty coastline of Wales. As a result of his youth his undercarriage is rusty wherever there isn't MB factory paint. This includes the threads on the massive U-bolts that hold the leaf stacks to the axle. I labored for an embarrassing amount of time using penetrating oil, wire brush, hammer driver, breaker bar, 4' cheater bar etc. with very little to show for it; headway on removing the nuts was painstakingly slow. Then the "little grey cells" (as Hercule Poirot would say) began to come alive and I realized I could just cut these U-bolts off because I just sold my firstborn for a set of new ones! Enter my Milwaukee angle grinder and cutoff wheel. Wam, bam, thank you ma'am.

After that it was a matter of pounding the leaf stack with a mini sledge until the rust broke loose in order to remove one leaf at a time.

With the leaf stack removed I was able to get a better look at what I'm calling the rear "sway bar" and its drop down brackets. The brackets are beyond leperous with rust to the point where replacement is necessary.

I've modeled up the bracket and am currently in the process of doing a proof-of-fitment test print on my 3D printer to see if I might be able to replace these brackets with carbon fiber/nylon 3D printed pieces rather than purchasing new ones or getting a new set fabricated.

So far I don't think I've ruined the truck and it actually feels like I'm making headway.

- Sheik

Last edited: