VerMonsterRV

Gotta Be Nuts

Great news! Can't wait to see it. Might even have to stop by on our way back south to see it in person ?.

Get your tickets to THE BIG THING 2026!

By shackles do you mean the upright links that went from the sway bar to the chassis? If so how strong is what you printed? If this is the part I am guessing yours were pretty rusted (poor design IMHO as the bottom end forms a nice cup), ours were. I had a local welding shop make some up. They are not super difficult.Lowly Update:

After wrestling (dealing with the learning curve) with my 3D printer I was finally able to successfully print the two rear sway bar shackles out of Carbon Fiber/Nylon:

View attachment 676022

Sourced some bushings to help distribute the fastener-shackle loads and it was time to assemble:

View attachment 676024

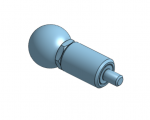

The assembled shackle with some of the assembly tools:

View attachment 676026

I was able to source the necessary replacement rubber bushings from Jim at EuroTech (www.UNIMOGS.com) for all of the front and rear sway bar attachment points - so nice to have a source for these sorts of rare items!

With fresh rubber installed it was time to reassemble the rear sway bar components back onto the truck:

View attachment 676028

View attachment 676029

- Sheik

Jon,By shackles do you mean the upright links that went from the sway bar to the chassis? If so how strong is what you printed? If this is the part I am guessing yours were pretty rusted (poor design IMHO as the bottom end forms a nice cup), ours were. I had a local welding shop make some up. They are not super difficult.

I like what I see so far... can't wait to see that awesome habitat on the back of this beauty.Let the story begin!

We just pulled the trigger on a MB 1120 4x4 Incident Response Vehicle at an auction in Wales, UK with the intent to turn it into a motorhome for an adventuring family.

We dub the truck "Lowly the Lorry".

View attachment 417160

View attachment 417161

I hope to adequately record the upcoming madness for the benefit of those who are curious at just how many screw-ups a crazy scheme like this can produce. I'll be the first to admit that this project may not ultimately succeed, but I figure it is worth a try to create some memories, give me more gray hair and serve as another money pit.

I'm currently jumping thru the hoops of transferring money, obtaining insurance, locating a parking/storage facility & relocating the vehicle from the auction house property to storage via email and an 8 hour time difference. Let the insanity begin! If anyone out there has experience doing this sort of thing who would shower me with hints/advice/suggestions, I'm waiting with soap-in-hand.

Cry for help #1: is there anyone in the EXPO universe located near the Cardiff or Bristol area of the UK who has a place to park a lorry like this for a short/medium term while I get my head wrapped around exactly how and where we are going to convert this beast.

Stay tuned, this could be better than daytime television!

- Sheik

Nice work, uhmw expands 5 times as fast as steel , do not try to maintain high tolerances. How are you keeping sand out of the bearing surfaces?

Good luck

Johan