Sigmataun49

BIFF

11/15/2015

We got some more work done yesterday at RESZ Fabrication. Cut some 2" square tube to make storage spots on both sides of the fenders.

After they were all cut, welded together, and welded onto the frame the trailer was really starting to look like something out of Mad Max.

These storage spots are strong!! Mike was standing on the front left as I stood on the rear right one. We quickly realized that I weighed more than Mike and that there is no jack stand in the rear of the trailer... yet. These swivel mount jack stands will be welded to all four storage areas. The jacks themselves can be taken off and stored inside the tongue box or inside the trailer. This is just mocked up for the time being, but they look like they will work just fine stabilizing the trailer while I am on top of it in a tent...

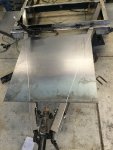

We then set the tub back in place and covered up the 2" square tube with some 1/8" sheet metal. After the sheet metal was welded into place the rear tail light housing was welded on top.

Stay tuned... next weekend will be fun filled... finishing covering the storage spots, welding on the other tail light housing, extending the tongue, adding HF tool box, welding on some more angle iron to support the Thule legs, s'more spot welds and grinding.. metal fab should be complete next weekend. We will then be off to the sand blaster to get all the old paint and rust off, after blasting bed liner will be applied. After that the final stop will be in Amish country to have a snap on cover made out of boat cover material so it is waterproof and will keep all of my gear from getting soggy.

I can not thank Mike @ RESZ Fabrication enough for all of his help, he has seriously busted out all of this metal work in a couple of weekends and it looks great!

We got some more work done yesterday at RESZ Fabrication. Cut some 2" square tube to make storage spots on both sides of the fenders.

After they were all cut, welded together, and welded onto the frame the trailer was really starting to look like something out of Mad Max.

These storage spots are strong!! Mike was standing on the front left as I stood on the rear right one. We quickly realized that I weighed more than Mike and that there is no jack stand in the rear of the trailer... yet. These swivel mount jack stands will be welded to all four storage areas. The jacks themselves can be taken off and stored inside the tongue box or inside the trailer. This is just mocked up for the time being, but they look like they will work just fine stabilizing the trailer while I am on top of it in a tent...

We then set the tub back in place and covered up the 2" square tube with some 1/8" sheet metal. After the sheet metal was welded into place the rear tail light housing was welded on top.

Stay tuned... next weekend will be fun filled... finishing covering the storage spots, welding on the other tail light housing, extending the tongue, adding HF tool box, welding on some more angle iron to support the Thule legs, s'more spot welds and grinding.. metal fab should be complete next weekend. We will then be off to the sand blaster to get all the old paint and rust off, after blasting bed liner will be applied. After that the final stop will be in Amish country to have a snap on cover made out of boat cover material so it is waterproof and will keep all of my gear from getting soggy.

I can not thank Mike @ RESZ Fabrication enough for all of his help, he has seriously busted out all of this metal work in a couple of weekends and it looks great!

Last edited: