No really exciting stuff happening I'm afraid - it's the 'you-can't-see-this-but-it's-really-important' stuff that is fiddly fiddly and taking up loads of time. Basically when I whacked the hole out of the roof I cut through the strengthening rib in the middle of the van, the one that runs across the width, and also the one that runs front to back. So to tie these four cut-points into the new structure I'm plugging the holes with some wood, which is screwed into place with a couple of screws coming up from below through the rib's alloy.

Once its hammered in and solidly fastened, the surplus is cut off.

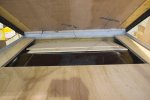

Then the square pine is installed, and screwed through in to the wood-filled rib. It forms the lowest part of what is basically a sandwich with the pine plate on top (as shown in previous post), the metal of the old roof, a packing piece, then square pine at bottom. A slim facing will cover the joint on the vertical face. And underneath this (above the white hooks) there will be a thin plywood veneer on an angle from the wood where the hooks are, up to the back of the lower edge of the square stuff. This will run from the back of the van to the point where it meets the slope above the drivers seat (where the fire extinguisher is). Behind the ply is a void into which I can run wiring or vents, piping or whatever, or recessed lights. On the outside of that void is the new void I've created between the outside of the old roof, and the back of the new alloy that forms the new roof. It's going to be pumped full of building foam.

I'm still weighing up options for the bed platform. I only need the rearmost bit, that floats over fresh air, to be reasonably thick and solid - the bit at the front can be thin ply (maybe 1/4" or 3/8") because its not weight bearing - only carrying our feet, or a small boy from time to time. The rearmost bit does need some bracing across the width but I'm leaning towards two pieces of alloy tube that can be stored out of the way and slipped in to take the weight when the bed platform is set up. Doing it that way means I don't have to fasten strengthening members to the actual board which will make its overall thickness increase which in turn will diminish the (already slim) storage space between bed and new roof.

Once its hammered in and solidly fastened, the surplus is cut off.

Then the square pine is installed, and screwed through in to the wood-filled rib. It forms the lowest part of what is basically a sandwich with the pine plate on top (as shown in previous post), the metal of the old roof, a packing piece, then square pine at bottom. A slim facing will cover the joint on the vertical face. And underneath this (above the white hooks) there will be a thin plywood veneer on an angle from the wood where the hooks are, up to the back of the lower edge of the square stuff. This will run from the back of the van to the point where it meets the slope above the drivers seat (where the fire extinguisher is). Behind the ply is a void into which I can run wiring or vents, piping or whatever, or recessed lights. On the outside of that void is the new void I've created between the outside of the old roof, and the back of the new alloy that forms the new roof. It's going to be pumped full of building foam.

I'm still weighing up options for the bed platform. I only need the rearmost bit, that floats over fresh air, to be reasonably thick and solid - the bit at the front can be thin ply (maybe 1/4" or 3/8") because its not weight bearing - only carrying our feet, or a small boy from time to time. The rearmost bit does need some bracing across the width but I'm leaning towards two pieces of alloy tube that can be stored out of the way and slipped in to take the weight when the bed platform is set up. Doing it that way means I don't have to fasten strengthening members to the actual board which will make its overall thickness increase which in turn will diminish the (already slim) storage space between bed and new roof.

Last edited: