The best RV surplus places are in Elkhart, Indiana. Elkhart is "the Detroit of the RV business", there are more RV companies there than anywhere else in the country. Because of that, quite a few RV surplus places exist where the manufacturers sell off their excess parts so there's always a great selection of things to build overland vehicles and campers with. My favorite is Bontragers (

https://bontragers.com/rv-supplies-accessories/). They don't list all of their inventory in detail on the web site though, so I always go there and search their several warehouses and usually find what I need. I've gotten many things at these places - windows, hatches, sinks and related parts when I was designing the MORryde Trail Kitchen sink option, wiring components, fabric, etc.

The rear of the roll bars is slanted so the soft top can hinge around them. If the rear of the bars were vertical there's no way the soft top could work the way it does.

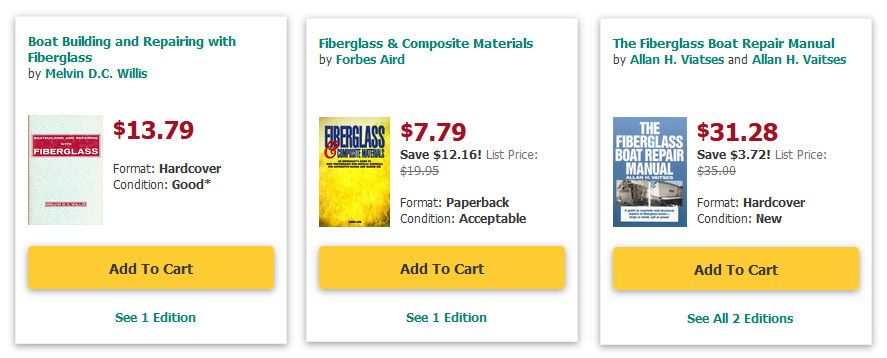

I'd recommend starting by reading a few books on fiberglass. Thriftbooks (and online used bookseller) has quite a few:

https://www.thriftbooks.com/browse/?b.search=fiberglass. I've got these in my library, they're all good:

The book on the left is from the 70's but the techniques you'll need haven't changed so older books are worth reading. The book in the middle is very comprehensive and I highly recommend it. The book on the right is useful too, modifying a hardtop and repairing a fiberglass boat basically involve the same processes, so it's worth reading too.

After reading a few books, I'd recommend starting with a small project that doesn't matter. For example, you might make a short section of drip rail, to give you practice in making a mold and making a fiberglass part. The mold can be made from wood (I can provide details to guide you) - you could make a short mold as practice, maybe 2' long. Once you've made a successful part you could go on to make a much longer mold to make the actual drip rail extensions you'll add to the hardtop. But making a part that doesn't matter is a great way to get started with the materials and techniques you'll need for parts that do matter.

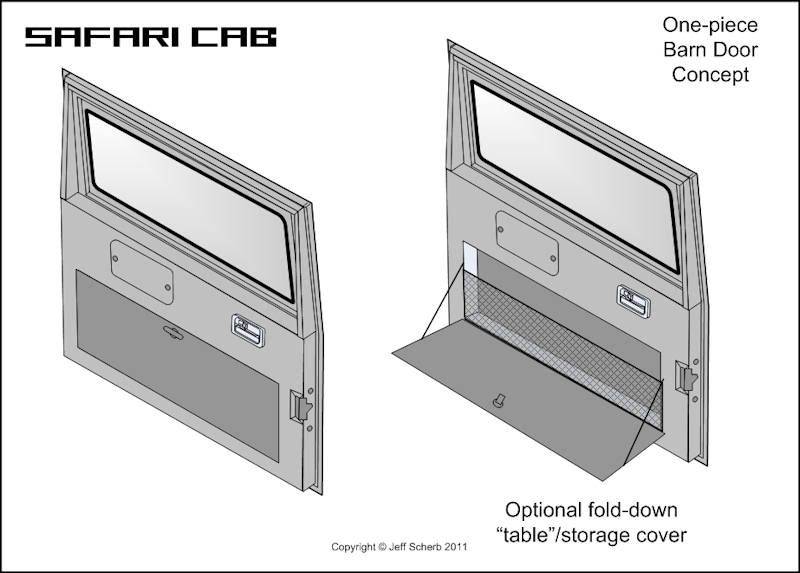

I often make molds for small parts out of wood, and very often make mold masters from wood. A mold master (sometimes called a pattern, or "plug" in the fiberglass business) is a wooden replica of the part you intend to make. A mold is made from that master and then the part is made in that mold. For examples, you can see the wooden mold masters I made for my barn door in the early pages of my barn door thread.