Neil

Observer

Hi Simon , looking fantastic.

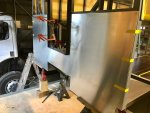

On a different note, your picture of the front end of the truck with its grills removed reminded me of something.

On the NG cab which is vey similar the cavity in the pillar on the right of your photo , accessed by the vertical elongated circular appeture, is a common location for corrosion. This is due to a build up of moisture in the cavity.

In the base of the cavity is a rubber drain plug that often gets blocked up. Many remove the plug completely.

Just a thought

Neil

On a different note, your picture of the front end of the truck with its grills removed reminded me of something.

On the NG cab which is vey similar the cavity in the pillar on the right of your photo , accessed by the vertical elongated circular appeture, is a common location for corrosion. This is due to a build up of moisture in the cavity.

In the base of the cavity is a rubber drain plug that often gets blocked up. Many remove the plug completely.

Just a thought

Neil