I agree Simon, strength wise as long as the composite box has reasonable front and rear walls, or internal bulkhead wall, they should be very strong in a slow roll over, but I have seen the photos of the fridge truck boxes fold flat because of the big doors at the rear letting go, so it the front or rear has large windows or door, it won't have much strength at all. Probably why you seldom see a window in the rear of the major expedition body manufacturer's vehicles.

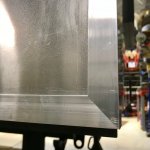

My main concern and why I didn't end up going the composite way was the out skin getting damaged by tree branches. I know of two composite box trucks, both by major manufacturers that have water leaks due to cracks in the outer skin. I've been in both an they have that musty old caravan smell to them. On mine, each seam in roof was covered with another piece of aluminium, all glued down to the water has a long way to get through to the inside. We had had one branch hit the truck so far, causing a dent in the aluminium high up on the top. We hit it at about 30kph, roof bars helped a bit, but it was quite a hit, the tree snapped off at the base (about 5" across) as we twisted the whole branch around.

I'm pretty sure a composite box would have survived OK as well, but would the outer skin have been cracked, especially those with the thin fibreglass skins? I think it would have.

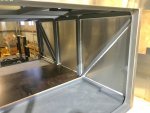

The otehr reason was I wanted it certified for rear passengers, my Engineer said he would want an internal steel cage if passengers were to be in the back in a composite box unless I could do the calculations to proved how strong it was. I designed my steel frame using the ADR bus code, same member sizes but at closer centres, and then a fully trussed cage front and rear section. He was happy that it passed the "Substantial" rule.

Mine is pretty lightweight compared to your Simon, I think yours would hold up falling down a mine shaft