Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Next generation snatch block

- Thread starter Vinman

- Start date

Nonimouse

Cynical old bastard

Interesting thread

I know Red Winches well - they are based about 20 miles down the road. I have written a number of articles about them and their products. They build good stuff. I trust them

I've just been given one of their Rings to test, along with a demo soft shackle from Ruftracks. I'm open minded about it.

I've been using synthetic line, for winching, for about 20 years now. I still use Fibre Core Steel rope for certain things. I no longer compete, but I teach winching and I'm an assessor for a truly internationally accepted winching qualification. I also recover plant, move timber, salvage and recover vehicles.

In the old days, I would wear out a Superwinch Pulley Block (it's not a snatch block) in a six month. So I moved over to TJM (with grease-able bush). They would last, at best a couple of years. Then I bought a roller bearing unit from a German lifting company. That's ten years old, this year.

So I use kit.

I don't use high speed winches. I prefer pulling power and efficiency. My weapon of choice at the moment is a G10, with a Bow2 and upgraded bearings

I can see a use for the Ring. It's light, simple and easy to use with gloves on (remember only a fool doesn't wear gloves). Metcalf has a point about it's inability to snag the synthetic line (which cheap or worn pulley blocks will do on a regular basis). I shall include it in my teaching. I'm going to knock up a version of Metcalf's block and strap concept, within the next few days. It makes sense - although I might use a block of cold pour polyurethane...

So to conclude, I think this clever and simple development has a place in our world, although there will undoubtedly be teething problems and the odd 'nay sayer'

I know Red Winches well - they are based about 20 miles down the road. I have written a number of articles about them and their products. They build good stuff. I trust them

I've just been given one of their Rings to test, along with a demo soft shackle from Ruftracks. I'm open minded about it.

I've been using synthetic line, for winching, for about 20 years now. I still use Fibre Core Steel rope for certain things. I no longer compete, but I teach winching and I'm an assessor for a truly internationally accepted winching qualification. I also recover plant, move timber, salvage and recover vehicles.

In the old days, I would wear out a Superwinch Pulley Block (it's not a snatch block) in a six month. So I moved over to TJM (with grease-able bush). They would last, at best a couple of years. Then I bought a roller bearing unit from a German lifting company. That's ten years old, this year.

So I use kit.

I don't use high speed winches. I prefer pulling power and efficiency. My weapon of choice at the moment is a G10, with a Bow2 and upgraded bearings

I can see a use for the Ring. It's light, simple and easy to use with gloves on (remember only a fool doesn't wear gloves). Metcalf has a point about it's inability to snag the synthetic line (which cheap or worn pulley blocks will do on a regular basis). I shall include it in my teaching. I'm going to knock up a version of Metcalf's block and strap concept, within the next few days. It makes sense - although I might use a block of cold pour polyurethane...

So to conclude, I think this clever and simple development has a place in our world, although there will undoubtedly be teething problems and the odd 'nay sayer'

roving1

Well-known member

Interesting thread

I know Red Winches well - they are based about 20 miles down the road. I have written a number of articles about them and their products. They build good stuff. I trust them

I've just been given one of their Rings to test, along with a demo soft shackle from Ruftracks. I'm open minded about it.

I've been using synthetic line, for winching, for about 20 years now. I still use Fibre Core Steel rope for certain things. I no longer compete, but I teach winching and I'm an assessor for a truly internationally accepted winching qualification. I also recover plant, move timber, salvage and recover vehicles.

In the old days, I would wear out a Superwinch Pulley Block (it's not a snatch block) in a six month. So I moved over to TJM (with grease-able bush). They would last, at best a couple of years. Then I bought a roller bearing unit from a German lifting company. That's ten years old, this year.

So I use kit.

I don't use high speed winches. I prefer pulling power and efficiency. My weapon of choice at the moment is a G10, with a Bow2 and upgraded bearings

I can see a use for the Ring. It's light, simple and easy to use with gloves on (remember only a fool doesn't wear gloves). Metcalf has a point about it's inability to snag the synthetic line (which cheap or worn pulley blocks will do on a regular basis). I shall include it in my teaching. I'm going to knock up a version of Metcalf's block and strap concept, within the next few days. It makes sense - although I might use a block of cold pour polyurethane...

So to conclude, I think this clever and simple development has a place in our world, although there will undoubtedly be teething problems and the odd 'nay sayer'

What is your usage cycle like that you are using up pulley blocks that fast?

Nonimouse

Cynical old bastard

Not as heavy as you'd think. But many times as much as most that are used for recovery. To be fair, the Superwinch/King One pulley blocks are cheap; in fact very cheap. Most come out of the box with too much play between the shears. They all need some adjustment. I'd estimate maybe 1.5 to 2k times a year, including double line and angle changes (but that's a low estimate). The Cheap pulley blocks are rated at 4.5 Tonnes SWL, whereas the TJM units are 7.5 tonnes SWL and the nice shiny Teutonic loveliness is rated at 10 tonnes SWL. I've also got an 8 Tonne Black Rat unit that has lasted as long as the German unit (Heinrich I think); I'm particularly fond of this one as it doesn't use a cir-clip to hold it together, rather an 'R' clip, so it's easy to pull apart and rebuild...What is your usage cycle like that you are using up pulley blocks that fast?

MartinDWhite

New member

There are definitely opinions both ways on these, but I love them so much I started making them. I worked with a small machine shop here in South Carolina, USA, and made another run of recovery rings. This time in orange. If anyone wants one, message me or check them out on ebay..... Yes I ship all over the world and Yes I have had these tested to determine the strength rating.

Recovery Ring for Offroad Winch (new) | eBay

A win win situation for everyone! If you have any doubts, do a google search on "recovery ring system". There are many useful videos and a lot of information on how to use them.

www.ebay.com

Metcalf

Expedition Leader

There are definitely opinions both ways on these, but I love them so much I started making them. I worked with a small machine shop here in South Carolina, USA, and made another run of recovery rings. This time in orange. If anyone wants one, message me or check them out on ebay..... Yes I ship all over the world and Yes I have had these tested to determine the strength rating.

View attachment 584989

Recovery Ring for Offroad Winch (new) | eBay

A win win situation for everyone! If you have any doubts, do a google search on "recovery ring system". There are many useful videos and a lot of information on how to use them.www.ebay.com

Good stuff. Great price point.

Any interest in selling in batches of 10 or so? Shoot me a PM.

MartinDWhite

New member

Good stuff. Great price point.

Any interest in selling in batches of 10 or so? Shoot me a PM.

There are definitively discounts available for purchasing multiple. Anyone interested should PM me. I ship world wide.

s.e.charles

Well-known member

I found this interesting:

MartinDWhite

New member

I make and sell solid recovery ring in the USA. PM me, or see the ebay link in my signature.Any dealers in US?

The heat issue was discussed earlier in this thread and it is just not possible to get it hot enough to do damage.I would think the soft shackle or rope used to attach the ring to your anchor would get very warm do to the friction. Would that heat weaken and cause excessive wear on that soft shackle or rope? Wouldn't the knot in the soft shackle or rope also be a weak point?

The knot is the weak spot in all soft shackles and is the point of failure in all the tests I have run. All the 1/2" soft shackle knots seem to fail about 40,000 lbs. IF you are putting that much on it, you are doing something wrong, or using the wrong gear.

DaveInDenver

Middle Income Semi-Redneck

I found this interesting:

Shackle to Shackle

Have you ever wondered if you can connect shackle to shackle? How about how tight to tighten the pin of a shackle? See what Crosby has to say about both.

news.thecrosbygroup.com

news.thecrosbygroup.com

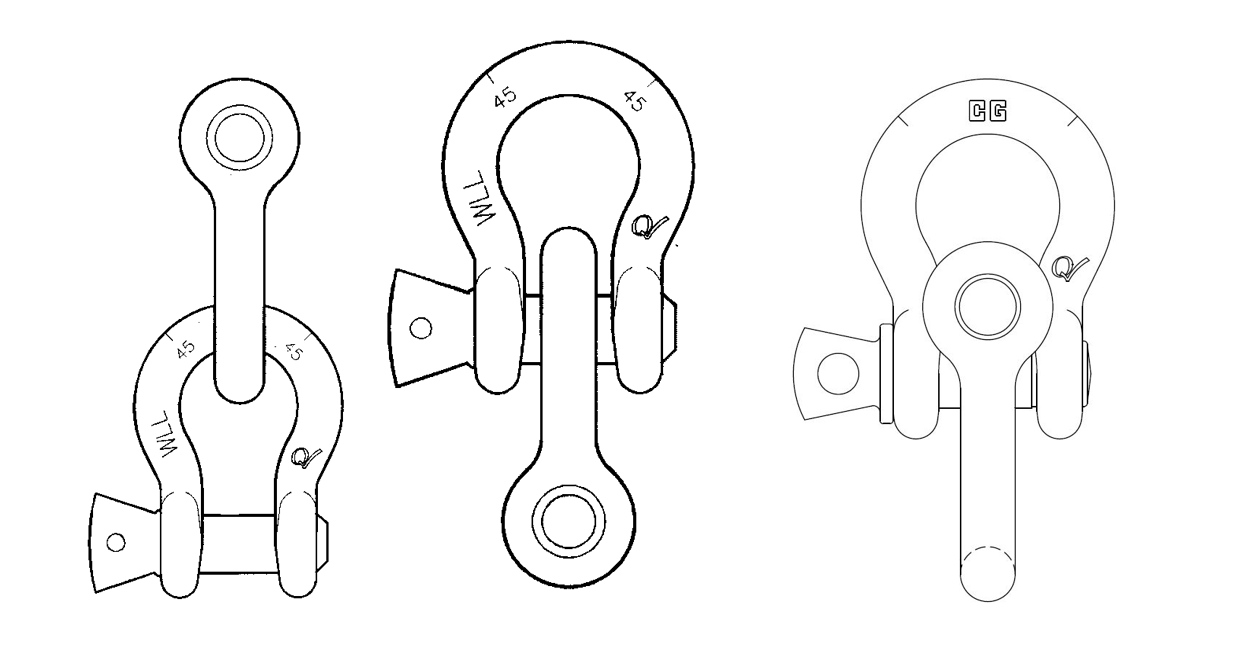

Connecting Shackle to Shackle

The popular Crosby forged chain and anchor shackles (3/16” – 3”) can be point to point loaded to the Working Load Limit without bending of the pin/bolt. Connecting bow to bow, or bow to pin is the preferred method. Connecting pin to pin is also acceptable if there is not interference between the diameter of the shackle ears.

No matter which method is used, caution should be given to maintain the load at the center of the span, by spacers on the shackle pin if necessary, to prevent the load or attaching shackle from sliding over to one side and concentrating loading near the shackle ear.

Keeping the load reasonably centered is key.

Tightening the Pin in a Screw Pin Shackle

First, Crosby states that screw pin shackles are to be used in pick and place applications.

Second, the pin must be tight before each lift and must not be able to be rotated while in use.

ASME B30.26 has the following statement regarding screw pin shackles:

The screw pin threads shall be fully engaged and tight and the shoulder should be in contact with the shackle body.

Thus, contrary to popular believe, you should never back off the screw pin before use. The shackle pin should be a minimum of hand tight before the lift begins.

Always make sure the shackle pin is tight!

If the screw pin cannot be threaded into the shackle by hand, this may be the result of deformation.

Note: For permanent or long-term application, use a bolt type shackle with bolt, nut & cotter or in any application that a screw pin shackle is used.

There's plenty of reasons why you certainly should avoid doing this, but I'll take Crosby's word as "knowing anything" over his generally speaking.

Last edited:

s.e.charles

Well-known member

I guess the ASME proof-reader was at lunch when this was relieved (sic):

"ASME B30.26 has the following statement regarding screw pin shackles:

The screw pin threads shall be fully engaged and tight and the shoulder should be in contact with the shackle body.

Thus, contrary to popular believe, you should never back off the screw pin before use. The shackle pin should be a minimum of hand tight before the lift begins."

"ASME B30.26 has the following statement regarding screw pin shackles:

The screw pin threads shall be fully engaged and tight and the shoulder should be in contact with the shackle body.

Thus, contrary to popular believe, you should never back off the screw pin before use. The shackle pin should be a minimum of hand tight before the lift begins."

DaveInDenver

Middle Income Semi-Redneck

Stoopid speel cheeker!I guess the ASME proof-reader was at lunch when this was relieved (sic):

"ASME B30.26 has the following statement regarding screw pin shackles:

The screw pin threads shall be fully engaged and tight and the shoulder should be in contact with the shackle body.

Thus, contrary to popular believe, you should never back off the screw pin before use. The shackle pin should be a minimum of hand tight before the lift begins."

View attachment 588869

There's plenty of reasons why you certainly should avoid doing this, but I'll take Crosby's word as "knowing anything" over his generally speaking.

I don't have much recovery experience and I'm trying to educate myself, so sorry if this is a dumb question. Regarding the frame at 10:29 that you posted, isn't his point in saying, "don't do this" the concern of adding weight and potential projectiles to the system?

DaveInDenver

Middle Income Semi-Redneck

He seems to mean within 4WD recovery, but his emphasis seems to imply it's not safe. It is generally safe to link shackles like that within a WLL standpoint, as Crosby's discussion states.I don't have much recovery experience and I'm trying to educate myself, so sorry if this is a dumb question. Regarding the frame at 10:29 that you posted, isn't his point in saying, "don't do this" the concern of adding weight and potential projectiles to the system?

The recovery question is philosophical. The argument goes that you want the least amount of mass hung out there and especially if it lacks support. That is indeed sensible. If you link two shackles like that it's twice the mass so there should be a real important reason you feel you must do that. I'm not arguing Crosby's answer means it's a good decision in our use, either.

But it's my opinion that if you do your assessment correctly and all your rigging is in good condition and within working load limits there's no reason to assume failure is foregone. Yes, of course there's unknowns, in particular connections to vehicles aren't universally safe and most have no rating, much less reliable testing. So I don't take exception to the soft rigging proponents on the mass. I just don't agree that it must be the most important characteristic above all. There's a time and place for all options and he does acknowledge that in his summary.

Last edited:

Thread bump. Anyone else see this video comparing blocks and rings? It seems more rigorously done than the one posted earlier in the thread (this one) and would seem to refute the idea that there’s a meaningful difference between efficiency and friction when comparing blocks and rings.

Last edited: