You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Overland Sprinter Build

- Thread starter luthj

- Start date

I'm glad you did explain why you made the decision you did. Anyone else reading this thread, with a different vehicle, might go another way.No worries, just explaining why I came to my decision.

You can have two of the following in overland vehicles, pick wisely.

Lightweight

Easy to Use

Inexpensive

Or might not.

Wyuna

Observer

In regards to those battery cells, i had a look at the page, but couldn't see a size for the individual cells, i'm guessing from the battery layout you already have the size.

what is the metric size of these cells, they don't look to tall either.

that would be a nice size battery bank.

what is the metric size of these cells, they don't look to tall either.

that would be a nice size battery bank.

luthj

Engineer In Residence

luthj

Engineer In Residence

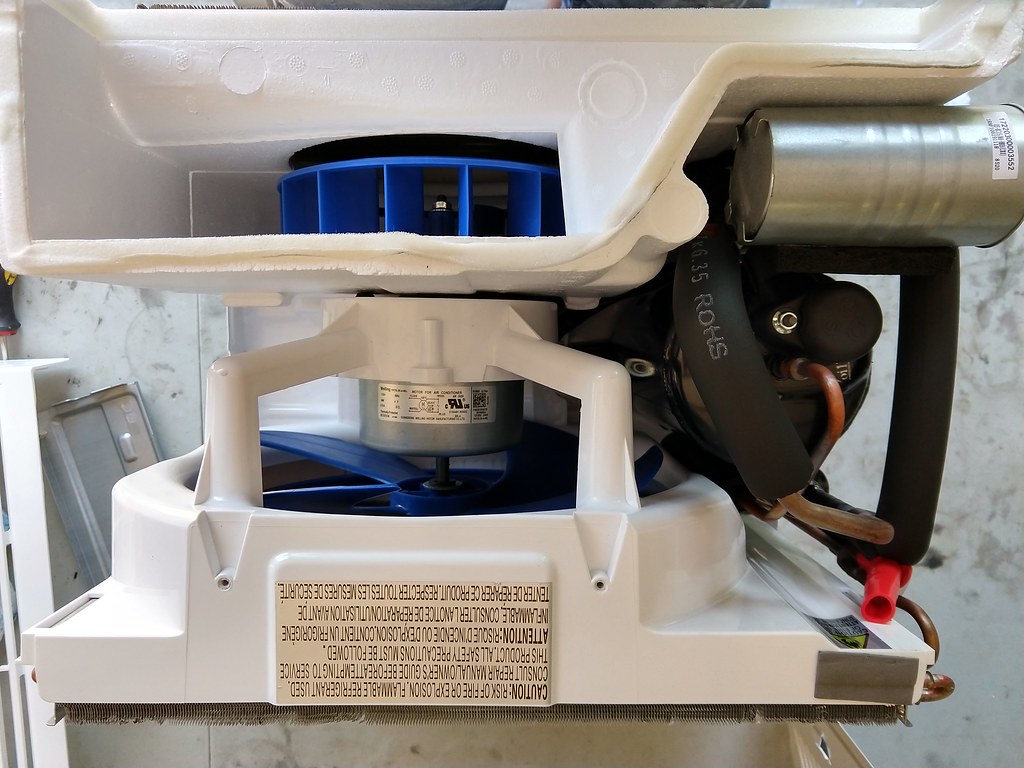

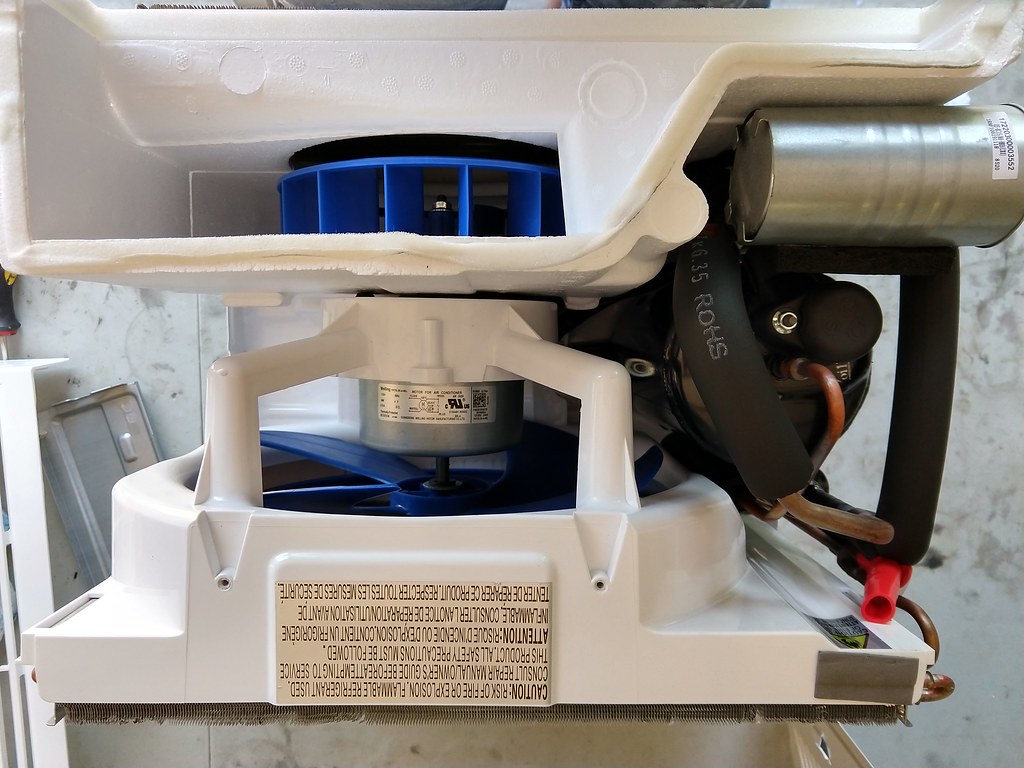

Started tearing down the AC unit.

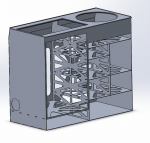

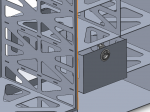

The evap and controls should fit over the bed with a little work. Looks like the best cut is along this line. That leaves the compressor and fan with the condenser.

The liquid line from the condenser is ~1/4" OD, then it goes to about 20 inches of capillary tube. The tube has some thick foam , followed by thin vinyl tubing. I plan to keep the cap tube with the evap, so I need 8-12ft of liquid line. Gas side return measures to ~3/8" OD. So they might be standard imperial sizes.

I am not sure if 3/8" is sufficient for the gas return. My first thought is that is should be okay for just 10ft.

The other issue is the cap tubes metering control. Since the tube will not be inside the cooled enclosure, it may be too short. I think there is enough insulation, that I can remove it to compensate if necessary.

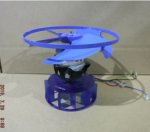

For the evap fan, I just ordered a used motor/fan from a similar model (28$ on ebay). Hopefully its a good fit. Since I am keeping the fan motor mount with the condenser, I will need to make something to support the evap fan. It appears that a flat mounting plate will work.

My current plan is to cut the unit in half, draw up the necessary metal bits to enclose both units, and to restore the drain pan on the evap. That will include a back wall to support the fan motor. At that point I can install and charge.

The evap and controls should fit over the bed with a little work. Looks like the best cut is along this line. That leaves the compressor and fan with the condenser.

The liquid line from the condenser is ~1/4" OD, then it goes to about 20 inches of capillary tube. The tube has some thick foam , followed by thin vinyl tubing. I plan to keep the cap tube with the evap, so I need 8-12ft of liquid line. Gas side return measures to ~3/8" OD. So they might be standard imperial sizes.

I am not sure if 3/8" is sufficient for the gas return. My first thought is that is should be okay for just 10ft.

The other issue is the cap tubes metering control. Since the tube will not be inside the cooled enclosure, it may be too short. I think there is enough insulation, that I can remove it to compensate if necessary.

For the evap fan, I just ordered a used motor/fan from a similar model (28$ on ebay). Hopefully its a good fit. Since I am keeping the fan motor mount with the condenser, I will need to make something to support the evap fan. It appears that a flat mounting plate will work.

My current plan is to cut the unit in half, draw up the necessary metal bits to enclose both units, and to restore the drain pan on the evap. That will include a back wall to support the fan motor. At that point I can install and charge.

Last edited:

luthj

Engineer In Residence

We have decided to go full-out on the van for the next 60 days or so. Galley, battery pack, shower, and some other storage upgrades are on the list. Its going to get busy. Then we should have the fall and winter to enjoy ourselves a bit before we start the job hunt again.

kikisadventures

New member

Just caught up on the thread. Great work and write up! It's super helpful for all of us starting our builds.

luthj

Engineer In Residence

I have a battery build going over here. Steel for the box is in the mail, and cells will be on a boat soon.

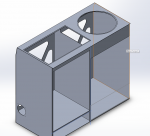

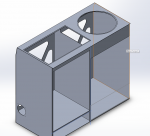

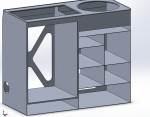

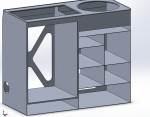

Making some progress on the galley. I think we have decided to go with aluminum bins. Still working on the counter material. I was thinking high density plywood, but I believe 1/4" aluminum will work. I can flush mount the cooktop and sink, and use another piece of AL welded to the bottom for support. I think I can break up some of the small bits to reduce shipping costs. I am going to be doing a lot of welding. I either need to buy a spoolgun and swap my gas out, or go with stick welding. I have some AL sticks to try out. If they work okay, that may be an cheaper option. Though my arc/stick skills are probably rough.

Making some progress on the galley. I think we have decided to go with aluminum bins. Still working on the counter material. I was thinking high density plywood, but I believe 1/4" aluminum will work. I can flush mount the cooktop and sink, and use another piece of AL welded to the bottom for support. I think I can break up some of the small bits to reduce shipping costs. I am going to be doing a lot of welding. I either need to buy a spoolgun and swap my gas out, or go with stick welding. I have some AL sticks to try out. If they work okay, that may be an cheaper option. Though my arc/stick skills are probably rough.

luthj

Engineer In Residence

Making progress on the galley design. I tried some of the SMAW/stick aluminum electrodes on some 0.1" aluminum I had lying around. The results were atrocious. Brutally hard to start at low amperage and very short arc length. The flux pool is indistinguishable from the metal pool. I can't get the arc to follow well either, as the flux forms a tube at low amps. They would probably work at high amperage on thick material, but not an option for me on this project. I gave in and ordered a spoolgun. If I am careful I should have enough C25 gas to finish the shower pan, then I can get an argon refill.

I picked up some 1/8" PE plastic to make fender flares. They turned out okay. I just need to find where I put the screws for them...

I picked up some 1/8" PE plastic to make fender flares. They turned out okay. I just need to find where I put the screws for them...

mountainhick

Member

I am thinking Southco M1 Latches. They have a model that works with 2-7mm thick front panels, which is ideal. I am not looking forward to welding all these bins up. But I am tired of water damage, splintered edges, and broken glue joints in wood.

Re: southco, We had the plastic version, they broke. Bad enough problem I redesigned galley and redid drawers with no latches. My no latch system is probably not appropriate for your metal drawers.

But, One drawer remains in another cabinet where I replaced plastic southco with knock off stainless version that cost around $8-9. It's fit/finish is not as good, but it is burly and holds up.

luthj

Engineer In Residence

But, One drawer remains in another cabinet where I replaced plastic southco with knock off stainless version that cost around $8-9. It's fit/finish is not as good, but it is burly and holds up.

I have had similar experiences on boats, so stainless was my go-to. Though I have heard they increased the glass fiber content of the plastic recently, but who knows. The southco original stainless are something like 30$+ each.

The galley looks like its going to be around 1,000$ with shipping. That using 0.1" 5052 AL, and 0.065 for the bins. Not cheap, but the extra storage is significant. Freeing up some space for an upgraded toaster oven, and a bit more clothing.

luthj

Engineer In Residence

Related, there are several mail order laser cutting services. I have had good luck with this one. Instant quotes, they meet their shipping deadlines, etc. There are several free cad programs you can use to draw a 2D part, and its effortless to upload and get a quote. No dealing with a surly guy on the phone. For small orders they have beat local places by a good margin, even with shipping.

www.oshcut.com

www.oshcut.com

Laser Cutting and Sheet Metal Services | OSH Cut

OSH Cut offers on-demand sheet metal laser cutting and bending services, with instant online quoting. Get your sheet metal parts as soon as next-day.

Similar threads

- Replies

- 1

- Views

- 418

- Replies

- 12

- Views

- 2K

- Replies

- 0

- Views

- 815

- Replies

- 3

- Views

- 572