You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

pivoting frames and mounting campers

- Thread starter lehel1

- Start date

Terrainist

Explorer

Thank you for posting those bushing photos and the spec's link Iandraz, and the video of your preliminary frame testing. Very helpful.

Last edited:

They look exactly like the bushings in the leaf springs in our Volvo. Wait... It runs on Trelleborg tires too...?!

M.Bas

Adventurer

I took a quick look in the Volvo Parts Catalogue and our rear suspension pivot consists of the big block holding the leafs in place, a big shaft running thru the block and frame mount and lots of bushes, spacers, shims and other stuff (PartsCatalogue22 page 11)They look exactly like the bushings in the leaf springs in our Volvo. Wait... It runs on Trelleborg tires too...?!

I took a quick look in the Volvo Parts Catalogue and our rear suspension pivot consists of the big block holding the leafs in place, a big shaft running thru the block and frame mount and lots of bushes, spacers, shims and other stuff (PartsCatalogue22 page 11)

I was reffering to the front springs. But let's not highjack the thread. It's really interesting!

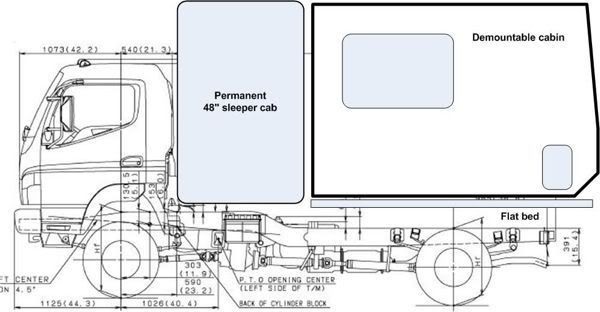

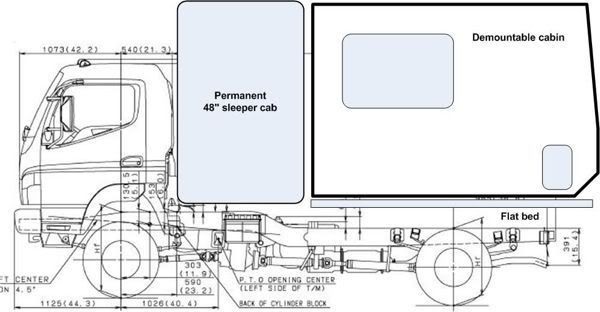

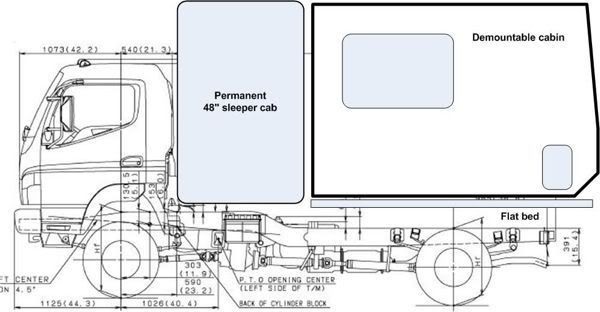

Mike Hiscox is selling a fiberglass shell that could be put on a Fuso

chassis like this:

This got me to thinking. Wouldn't a two piece camper/storage

setup like this be less susceptible to damage when the chassis

twists along its longitudinal axis? And wouldn't this arrangement

interfere less with frame flex that brings the front and rear axles

closer/farther away to each other?

I know there are practical reasons why a one-piece camper would

generally be preferred (more interior room, for one). But the two

box approach might work better off-road.

Chip Haven

chassis like this:

This got me to thinking. Wouldn't a two piece camper/storage

setup like this be less susceptible to damage when the chassis

twists along its longitudinal axis? And wouldn't this arrangement

interfere less with frame flex that brings the front and rear axles

closer/farther away to each other?

I know there are practical reasons why a one-piece camper would

generally be preferred (more interior room, for one). But the two

box approach might work better off-road.

Chip Haven

DiploStrat

Expedition Leader

Should Work

Chip,

Isn't it basically a trade off between camper stiffness/weight and frame stiffness/strength/weight?

-- If you had a perfectly stiff frame, then you could make your camper out of paper.

-- If your camper were pefectly rigid, then it would actually stiffen the frame. (Think monocoque constuction.)

-- Finally, the larger the structure, the harder it is to make it stiff.

Your practical decisions are probably driven by things you can't control:

-- Camper manufacturers tend to build for light weight, low cost, and good roads.

-- Truck manufacturers build for low cost and good fuel mileage.

Thus when you want to build to "Expedition" as opposed to "weekend" spec, it gets hard and expensive. (Duh!)

So I would agree with you - it should be easier to control flex, etc., in two smaller boxes, rather than one larger one.

Given that the usual worry is given as the collapse of interior partitions, etc., I wonder if we aren't missing a trick. Why not reinforce some of those partitions to make them part of the solution, not the problem?. (Replace that particle board with ply, or an aluminum frame.) This is part of the "secret" behind the Four Wheel Camper and its descendent, the Provan Tiger CX. Look at their frames - they are a honeycomb of aluminum.

As always, free advice is worth what you pay for it.

All the best,

Chip,

Isn't it basically a trade off between camper stiffness/weight and frame stiffness/strength/weight?

-- If you had a perfectly stiff frame, then you could make your camper out of paper.

-- If your camper were pefectly rigid, then it would actually stiffen the frame. (Think monocoque constuction.)

-- Finally, the larger the structure, the harder it is to make it stiff.

Your practical decisions are probably driven by things you can't control:

-- Camper manufacturers tend to build for light weight, low cost, and good roads.

-- Truck manufacturers build for low cost and good fuel mileage.

Thus when you want to build to "Expedition" as opposed to "weekend" spec, it gets hard and expensive. (Duh!)

So I would agree with you - it should be easier to control flex, etc., in two smaller boxes, rather than one larger one.

Given that the usual worry is given as the collapse of interior partitions, etc., I wonder if we aren't missing a trick. Why not reinforce some of those partitions to make them part of the solution, not the problem?. (Replace that particle board with ply, or an aluminum frame.) This is part of the "secret" behind the Four Wheel Camper and its descendent, the Provan Tiger CX. Look at their frames - they are a honeycomb of aluminum.

As always, free advice is worth what you pay for it.

All the best,

whatcharterboat

Supporting Sponsor, Overland Certified OC0018

Hi Again Chip. Sure the body may fare better when twisting but definitely "No". This should be avoided especially on an FG. We've mentioned that the weight should be supported along the entire length of the chassis.

http://i188.photobucket.com/albums/z241/expeditioncampers/HiscoxShellonFG.jpg

If you look at the diagram you see that the rear body mass is roughly centred over the rear axle. As you travel over bumpy / roads the weight of the body would tend to move fore and aft in an arc over the axle and probably force a chassis failure if the weights are enough. We have seen this happen more than once. This is especially not recommended on an FG cause of the thinner rails.

Supporting the weight right through to the cab on full length bearers is considered "best practice" in order to maintain chassis integrity.

You are right about putting less strain on the camper body but it's not the answer.

http://i188.photobucket.com/albums/z241/expeditioncampers/HiscoxShellonFG.jpg

If you look at the diagram you see that the rear body mass is roughly centred over the rear axle. As you travel over bumpy / roads the weight of the body would tend to move fore and aft in an arc over the axle and probably force a chassis failure if the weights are enough. We have seen this happen more than once. This is especially not recommended on an FG cause of the thinner rails.

Supporting the weight right through to the cab on full length bearers is considered "best practice" in order to maintain chassis integrity.

You are right about putting less strain on the camper body but it's not the answer.

DiploStrat

Expedition Leader

Hmmm!

Comments from someone who actually knows the truck! Most interesting.

One could speculate that it might have been exactly this kind of stress that cracked M. Hackney's frame. Was not his motocycle garage rigidly mounted?

The Mitsubishi is appealing to U.S. buyers as it has factory 4x4. I would note however, based on limited observation around here that:

-- The Mitsubishi is really a rather light weight urban delivery truck, with relatively small tires (7.50x16)

-- Thus the Aussies do a lot of work with wheels and axles.

-- With such a light frame, reinforcement might thus be the first goal, whether your final element pivots or not. Thus a "rigid" camper (See Michael Groves) might be a valid approach.

More free hot air on a slow morning.

Comments from someone who actually knows the truck! Most interesting.

One could speculate that it might have been exactly this kind of stress that cracked M. Hackney's frame. Was not his motocycle garage rigidly mounted?

The Mitsubishi is appealing to U.S. buyers as it has factory 4x4. I would note however, based on limited observation around here that:

-- The Mitsubishi is really a rather light weight urban delivery truck, with relatively small tires (7.50x16)

-- Thus the Aussies do a lot of work with wheels and axles.

-- With such a light frame, reinforcement might thus be the first goal, whether your final element pivots or not. Thus a "rigid" camper (See Michael Groves) might be a valid approach.

More free hot air on a slow morning.

dzzz

™

Mike Hiscox is selling a fiberglass shell that could be put on a Fuso

chassis like this:

This got me to thinking. Wouldn't a two piece camper/storage

setup like this be less susceptible to damage when the chassis

twists along its longitudinal axis? And wouldn't this arrangement

interfere less with frame flex that brings the front and rear axles

closer/farther away to each other?

I know there are practical reasons why a one-piece camper would

generally be preferred (more interior room, for one). But the two

box approach might work better off-road.

Chip Haven

Having the space in three section makes the space much less usable. A sportsmobile long van setiup would be more useful, I think.

dzzz

™

Well after weeks of research the only reason I can see why they make the chassis a C section and flexible is cost, they are cheap to make and assembly is easy, as my chassis is unusable I am contemplating making a rigid

chassis, all comments appreciated.

I think frame changes need to be engineered. Did Hakney's frame break because it was strengthened? Or because it was overloaded? I expect both. That stiffening and/or supporting created a hot spot.

One thing for certain with the lightweight FG is that one needs to live within a weight budget when designing and using.

Terrainist

Explorer

Generally speaking, on single axle trucks that have the frame fatigue and break due to load, they break over the rear axle, or close to the rear axle spring mounts.

The second place the frame will want to break, typically, is somewhere close to the midpoint between the front and rear axles.

And these are the two areas that failed on that truck, first the rear axle area, and then the midpoint area was beginning to show signs of failure. That's the gist I got of everything anyway.

The second place the frame will want to break, typically, is somewhere close to the midpoint between the front and rear axles.

And these are the two areas that failed on that truck, first the rear axle area, and then the midpoint area was beginning to show signs of failure. That's the gist I got of everything anyway.

Last edited:

Terrainist

Explorer

A quick and dirty way to see why truck frames break the way they do is to sit down at a desk, take a pencil and place it vertically on the desk in front of you. That's a rear axle. Now take another pencil and place it cross wise, split left to right, perpendicular, on top of the lower pencil. That's a frame rail. If one were to push down on the ends of the pencil on top, it would break right at the pencil underneath it, or at the axle.

Same deal with the other failure area...two pencils vertically in front on the desk. These are the front and rear axles of a truck. Place another pencil across and push down in the middle. You get the idea. Sort of a juevenille way to explain it, but that's the way I always think about it.

Same deal with the other failure area...two pencils vertically in front on the desk. These are the front and rear axles of a truck. Place another pencil across and push down in the middle. You get the idea. Sort of a juevenille way to explain it, but that's the way I always think about it.

. Did Hakney's frame break because it was strengthened? .

Not initially as I recall. He used the original frame with some lengthening when he built but I don't recall any strengthening until he had some frame problems. Weight on the other hand. . .

Similar threads

- Replies

- 33

- Views

- 4K

- Replies

- 3

- Views

- 1K

- Replies

- 25

- Views

- 5K

- Replies

- 0

- Views

- 554

- Replies

- 37

- Views

- 5K