DESIGN QUERY re PIVOTING FRAMES

Great thread – incredibly informative!

Perhaps the link has already been posted, but one possible interesting design variant was dubbed by its inventor the

“two line pivot floating subframe” – see

http://www.kookynet.net/220-cristo-3-ch04-subframe.html .

*****************************************

The following is a very long post, but I have some rather pressing design questions, questions that I was hoping those with some engineering knowledge and/or practical experience of frame/subframe systems, might be able to answer....

*****************************************

1) The MAN SX 45

A number of times in this thread, a question has arisen:

“Why not just build a chassis frame that is super-rigid, and 100 % torsion free, allowing just a suspension system with extremely long travel to handle the terrain?”

It does seem as if such a solution exists, in the form a very large military truck designed for extreme off-road use: the

MAN SX 45, “extreme-mobility”, 8 x 8, all-wheel-drive military truck. See

http://freundeskreis-videoclips.de/wordpress/wp-content/uploads/2009/01/the_mobility_elite.pdf ,

http://en.wikipedia.org/wiki/MAN_SX ,

http://www.military-today.com/trucks/man_sx45.htm , and

http://snafu-solomon.blogspot.it/2013/12/rheinmetall-man-military-trucks-keep.html .

The first link is to a PDF that was once available on the “MAN Military Trucks” website. But it seems that MAN’s military division went through a reshuffle, and is now owned / handled / operated by

“Rheinmetall Defence” – see

http://www.rheinmetall-defence.com/en/rheinmetall_defence/systems_and_products/vehicle_systems/military_trucks/index.php ,

http://www.rheinmetall.com/en/rheinmetall_ag/press/news/aktuell_1/news_details_2688.php , and

http://www.rheinmetall.de/media/editor_media/rheinmetallag/group/publications_1/companymagazine/newsline/2010_2/Newsline_01_2010.pdf . Unfortunately, Rheinmetall Defence website is much less forthcoming with information, in contrast to the older, now-defunct MAN military division website. So the link just given for the PDF is to a third-party website; hope the link stays active for a while!

Now browsing through this PDF -- again, at

http://freundeskreis-videoclips.de/wordpress/wp-content/uploads/2009/01/the_mobility_elite.pdf -- one sees that it describes the MAN SX 45 specifically as having an

“extremely torsion resistant box frame” , one that provides

“100 % torsional stiffness”. Instead, the MAN SX 45 absorbs all terrain irregularities through its progressive coil spring suspension. And the promised result is that

“the body remains unaffected even during fast off-road driving!!”

Does this strike the contributors in this thread as plausible? Wouldn't such a truck still need some kind of pivoting sub-frame for mounting a body?

Or is it indeed possible to eliminate all torsional twisting with a chassis box frame, in a vehicle this large, about 10 m long….?

*****************************************

2) Brief Note

The SX 45 is basically a “souped up” version of the MAN TGA construction truck, a line of MAN trucks now supplanted by the TGS series -- see

http://www.truck.man.eu/global/en/index.html ,

http://www.truck.man.eu/global/en/building-site-and-heavy-duty-transport/tgs/overview/Overview.html ,

http://www.truck.man.eu/man/media/en/content_medien/doc/business_website_truck_master_1/TGS.pdf ,

http://www.truck.man.eu/man/media/content_medien/doc/business_website_truck_master_1/Spezialfahrzeuge.pdf ,

http://www.man-bodybuilder.co.uk/drawings/euro5/ , and

http://www.man-bodybuilder.co.uk/drawings/euro5/chassis/81.99126.0055.04.pdf .

In both the TGS and the SX 45 the two front axles are steerable, but the TGS is 8 x 4 instead of 8 x 8. And of course everything about the SX 45 has been “militarized”, including the ability to withstand outside temperatures from minus 32 to plus 49 degrees Celsius!

*****************************************

3) “Fully Integrated” Expedition Mobile Home?

My second question is more of a design query. Some of the largest expedition vehicles made by ActionMobil or Armadillo (a Chinese company), are based either on a Mercedes Benz Zetros chassis, or a MAN TGA chassis, or more recently on a MAN TGS chassis. For examples of ActionMobil vehicles, see

http://www.actionmobil.at ,

http://www.actionmobil.at/page12/page12.html , and

http://www.actionmobil.at/page16/page16.html . And for Armadillo vehicles, see

http://www.armadillo-rv.com ,

http://www.armadillo-rv.com/Product.aspx ,

http://www.armadillo-rv.com/ProductDetail.aspx?ProductID=7 ,

http://www.armadillo-rv.com/ProductDetail.aspx?ProductID=18 ,

http://www.armadillo-rv.com/ProductDetail.aspx?ProductID=23 , and

http://www.armadillo-rv.com/ProductDetail.aspx?ProductID=15 . Just click on the images on the Armadillo product-range page (the second link provided), and you’ll be able to see copious photographs of all Armadillo vehicles.

I provided lots of Armadillo links, because if you can’t read Chinese, you might find their website difficult to navigate. But Google "translate" renders the website reasonably accessible. For instance, check out some great videos of Armadillo vehicles negotiating sand dunes in (what must be) the Taklamakan desert, at

http://translate.google.co.uk/translate?hl=en&sl=zh-CN&u=http://www.armadillo-rv.com/&prev=/search%3Fq%3Darmadillo%2Brv%26biw%3D1885%26bih%3D1102 , and click on "Audio/Data".

From a design point of view, let’s just say that the Chinese are “catching up”, and the interiors of many of these Armadillo vehicles are detailed to a level that might leave ActionMobil and UniCAT customers green with envy! My favorite is a really spectacular pop-up at

http://www.armadillo-rv.com/ProductDetail.aspx?ProductID=18 . UniCAT, eat your heart out! (Disclosure: I am German/Canadian).

Now all of these large expedition mobile homes follow a standard design format, in which a structurally separate, comparatively “short” cab (less than 3 m in length), is followed by a very long body (7 or 8 m in length), the latter mounted on a 3-point pivoting subframe. In the Zetros, however, the cab itself is

also mounted on 3-points – see

http://www2.mercedes-benz.co.uk/content/unitedkingdom/mpc/mpc_unitedkingdom_website/en/home_mpc/Unimog/home/unimog_overview/zetros/zetros/technical_data.html and

http://www2.mercedes-benz.co.uk/content/media_library/unitedkingdom/mpc_unitedkingdom/Unimog/pdfs/zetros/zetros_brochure.object.Single.File.tmp/Zetros%202011.pdf . And earlier in this thread, a contributor wrote that in a UNIMOG,

everything is mounted on separate 3 point subframes – the engine, the cab, the body, everything.

So I was wondering:

Could it in principle be possible to change the size-ratios of Cab-to-body, in a very large expedition vehicle?

Imagine instead that in an Armadillo or ActionMobil motorhome (based on a MAN TGS chassis), the Cab were lengthened to 4 or 5 m, and that this "first half" of the vehicle were fully fused with living quarters, as in

“fully integrated” motorhomes.

For a visual example of what I have in mind, see for instance

The Hymer Starline, a large

“fully integrated” German motorhome, in which the front seats can swivel around 180 degrees, and do “double duty” as chairs providing seating at a dining table:

http://www.hymer.com/en/ ,

http://www.hymer.com/en/models/ ,

http://www.hymer.com/en/models/integrated/hymer-starline/overview.html#.UtE_6HmK05A ,

http://www.hymer.com/en/models/integrated/hymer-starline/hymer-starline-s/experience.html#.UtFAD3mK05A ,

http://www.hymer.com/assets/images/modell-2014/hymer-starline-s/impressionen/HY13_BM680S_I_Sitzgruppe_Leder_Kiesel_0.jpg , and

http://www.hymer.com/assets/images/modell-2014/hymer-starline-s/impressionen/HY13_BM680S_I_Sitzgruppe_Leder_Kiesel_1.jpg :

By way of contrast, most expedition motorhomes -- of the sort offered by ActionMobil, UniCAT, Armadillo, et al -- seem to be very space-wasteful, because the seating used for driving never does “double duty” as seating for dining. Instead, the cab remains a separate, short box at the front, and then a second set of seats has to be provided for the camper in the back, for dining.

However, if the cab were lengthened 3, 4, or 5 m, and became the “first half” of the vehicle; and if it were then connected to the second half, also 4 or 5 m long, by an accordion-type “tunnel” located in the middle of the vehicle, then a “fully integrated” design similar to the Hymer might become possible.

Sure, there would still have to be an accordion-type tunnel connecting the front half (4 or 5 m long) and the rear half (4 or 5 m Long) -- an accordion-type tunnel located in the middle of the vehicle. But from a space-usage point of view, these two, roughly equal-length halves would offer design possibilities that the traditional “semi-integrated” or “non-integrated” expedition motorhomes simply do not. In effect, almost all expedition motorhomes designed and sold thus far have been “semi-integrated” or “non-integrated”. The only exceptions might be some expedition-capable van conversions, which one could describe as “fully integrated”.

So the engineering questions here are::

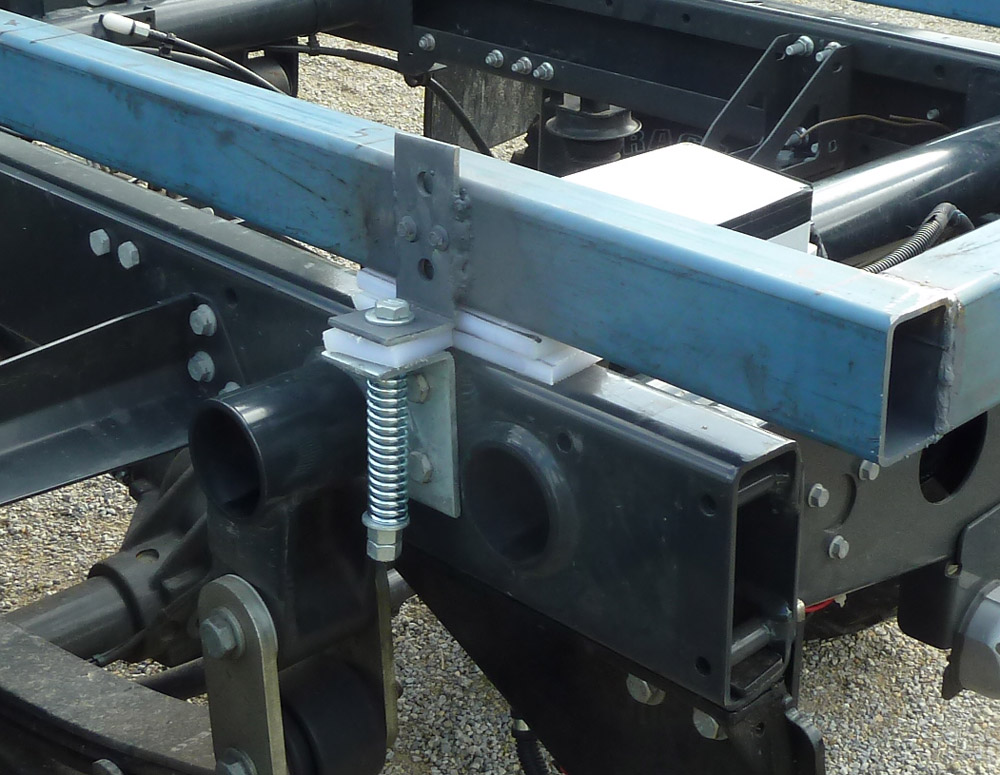

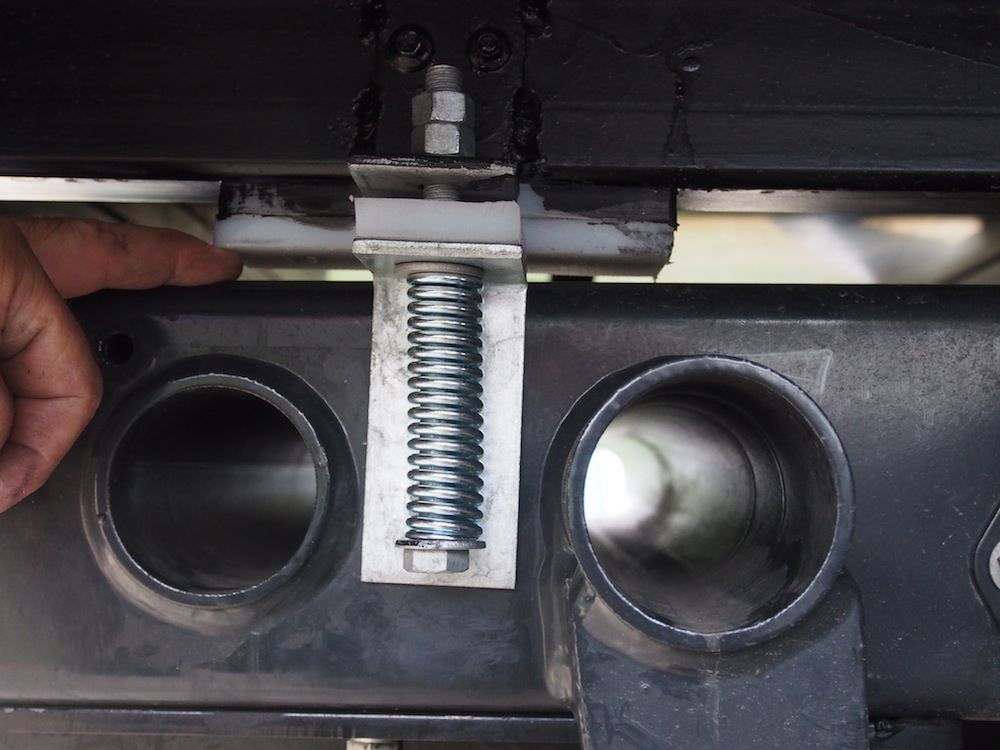

A. Would it be possible to construct an expedition motorhome with a “Cab” and a “Body” of roughly equal length (both of them 4 - 5 m long), both mounted on separate, 3-point pivoting sub-frames, and connected by an accordion-type tunnel in the middle?

B. What would be the engineering challenges of such a design?

C. How big could the accordion-type tunnel located in the middle of the vehicle be? How tall? How wide?

D. And most critically, where would one locate the pivots for the two halves, front and back?

Presumably, if the underlying Chassis were a MAN TGS 8 x 4 (as per the biggest Armadillos), then the front half (call it the "cab") would mount on two points above the first pair of axles, and would have its third pivot located near the middle of the vehicle; while the back half (call it the "camper" or the "body") would mount on two points located above the second pair of axles, at the rear of the vehicle, but again would have its third pivot also located near the middle of the vehicle?

But I am not an engineer, so I really don’t know the answer to this second subset of questions…..

For now, just "bracket" what happens to the engine, which in any case would probably mount separately at the very front, under a "nose" or "bonnet", as per the Zetros off-road truck. As Mercedes has realized, the cab-over-engine design of Euro-style trucks like the MAN TGS might be fine for highway driving, but for off-road driving, cab-over-engine is ergonomic hell (again, see the link to the Zetros PDF above).

So in the design that I am proposing, there might be at least three, separate, 3-point mounts:

(a) the engine, under a bonnet at the very front;

(b) the 4 - 5 m long "cab", or first half of the vehicle;

and

(c) the 4 - 5 m long "body", or second half of the vehicle.

For what it's worth, this also seems to be the mounting format of the Zetros, except that the "cab" of the Zetros is only about 2 m long.

*****************************************

A bit more about me: I am a student studying Transportation Design at an Art School in England, whose thesis project is -- you guessed it -- designing a very large, experimental, offroad-capable mobile home. So the questions above are really “design possibility” questions. I am curious about what might actually be structurally feasible, from an engineering point of view, in a very large, off-road, expedition-type motorhome.

Many thanks in advance for any and all responses!

Biotect