You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

pivoting frames and mounting campers

- Thread starter lehel1

- Start date

dhackney

Expedition Leader

Anyone know if there are pictures of the Santek system on the net?

I've got photos of the system and the current situation but Michel asked me not to share them on the forum.

Byrdseye

Observer

"There wasn't anybody around the Unicat rigs when I shot those photos to ask permission. "

Thomas tossed me out of the MXT Unicat for taking a picture inside.........In retrospect, I really should have asked first..... but I didn't appreciate attitude. (It was an Expo wasn't it?)

Everyone else at the event was very gracious and more than willing to share ideas and information (especially Mike Van Pelt with his GXV Unimog) and it was a great event with a lot of knowledge to tap into.

Thomas tossed me out of the MXT Unicat for taking a picture inside.........In retrospect, I really should have asked first..... but I didn't appreciate attitude. (It was an Expo wasn't it?)

Everyone else at the event was very gracious and more than willing to share ideas and information (especially Mike Van Pelt with his GXV Unimog) and it was a great event with a lot of knowledge to tap into.

dzzz

™

Not cleaning up the welds on the ecoroamer is neither structurally unsound or indicative of a bad design. But it's not great marketing.

But I just don't know about stiffening the frame like that. It may be able to transfer a torquing movement across the truck, but what other damage will be done to the camper?

Did unicat really adopt there box to that truck? What is that, an International? I doubt that truck will flex nearly as much as a unimog. I can't see driving that truck on forest roads in North America. It looks extremely tall.

Edit: Well O.K. those twisted bolts on the ecoroamer look pretty bad. It seems obvious that they wouldn't take the sheer force

But I just don't know about stiffening the frame like that. It may be able to transfer a torquing movement across the truck, but what other damage will be done to the camper?

Did unicat really adopt there box to that truck? What is that, an International? I doubt that truck will flex nearly as much as a unimog. I can't see driving that truck on forest roads in North America. It looks extremely tall.

Edit: Well O.K. those twisted bolts on the ecoroamer look pretty bad. It seems obvious that they wouldn't take the sheer force

Last edited:

dzzz

™

As someone planning to build, let me ask a question. When In doubd why don't most people just build on a three point pivot? Perhaps with some design to give the frame a "soft landing" if the pivot runs of of clearance?

At least doing it this way lets the frame perform as the manufacturer intended. Greatly stiffening the frame works against keeping the wheels on the ground.

It seems to me that 1) allowing for frame twist and 2) building a really stiff box that resists twisting motion produces good results.

It's way more suspension design than the average RV or truck camper gets.

And who is this famous frame builder Mark Johnson? I need a frame.

At least doing it this way lets the frame perform as the manufacturer intended. Greatly stiffening the frame works against keeping the wheels on the ground.

It seems to me that 1) allowing for frame twist and 2) building a really stiff box that resists twisting motion produces good results.

It's way more suspension design than the average RV or truck camper gets.

And who is this famous frame builder Mark Johnson? I need a frame.

charlieaarons

Explorer

Did unicat really adopt there box to that truck? What is that, an International? I doubt that truck will flex nearly as much as a unimog. I can't see driving that truck on forest roads in North America. It looks extremely tall.

Unicat custom built the box for that MXT-MV chassis. They can build any size/shape box needed by cutting and gluing those panels.

Unicat's workmanship is truly first class. My camper has survived outdoors for 2 Alaska winters so far, then only winter prep is blowing out the water lines in the fall.

Charlie

As someone planning to build, let me ask a question. When In doubd why don't most people just build on a three point pivot?

.

See the threads on Doug Hackney's frame issues for an answer to that question.

dzzz

™

See the threads on Doug Hackney's frame issues for an answer to that question.

Doug has a camper on a FG, right? I do remember he cracked the frame. But he's gone a long way with an unusual setup

ntsqd

Heretic Car Camper

An aspect of the Ecoroamer design that seems to have been overlooked is that the flat plate between pairs of rubber mounts can act as a very stiff leaf spring. I think that it is an idea worth pursuing. Simple and effective. Longevity would be the issue that I can only make a guess on. I suspect that to take full advantage of the concept that only a single middle mount should be used. The end pair would essentially be the shackles and the middle one would be the fixed point. For the maximum longevity the plate itself should be made from spring material. The idea would allow for tuning of the amount of flex in the box or deck's suspension by varying the width, length, and thickness of the leaf - just like with any leaf sprung suspension.

I am under the impression that the Ecoroamer is not a prototype of something that will eventually be for sale, but rather a one-off, custom build. Please correct me if that is not the case.

Where I come from chassis flex is frowned upon and actively worked against. Chassis flex is a spring that you can not easily tune or account for. An uncontrollable variable - better to eliminate it.

I realize that this really isn't feasible or possible with a ladder frame of this length, but the very idea of designing to flex it intentionally is abhorrent to me. Designing to deal with it's undesired flex is another thing entirely.

I would think that with a box of the size usually used on trucks of this size that one could design the structure with enough torsional strength that any sort of flexible mounting method would be unnecessary. Obviously that isn't so easily done or it would have been the path long taken.

I am under the impression that the Ecoroamer is not a prototype of something that will eventually be for sale, but rather a one-off, custom build. Please correct me if that is not the case.

Where I come from chassis flex is frowned upon and actively worked against. Chassis flex is a spring that you can not easily tune or account for. An uncontrollable variable - better to eliminate it.

I realize that this really isn't feasible or possible with a ladder frame of this length, but the very idea of designing to flex it intentionally is abhorrent to me. Designing to deal with it's undesired flex is another thing entirely.

I would think that with a box of the size usually used on trucks of this size that one could design the structure with enough torsional strength that any sort of flexible mounting method would be unnecessary. Obviously that isn't so easily done or it would have been the path long taken.

Byrdseye

Observer

I'm with ntsqd.......In the racing world, where my work experience comes from, a flexy chassis is avoided like the plague. It's much better (and easier) to let the suspension do all the work as it can be easily data logged and tuned for spring rate, ride height, rebound/compression damping, travel etc. However, as has been mentioned, it is just not possible to keep a ladder frame from twisting at least a bit. I think one would need to build a very stout monocoque caged box integral to the frame (check out most any race machine) and there are reasons why that often isn't the most practical solution when building an expedition type of rig. In my view, the Eco-Roamer is a bit of a hybrid in this regard with it's welded box construction. I think it may help to minimize the frame flex and be resistant to twisting itself.............time and mileage will tell.

(Also, please don't think I was dissing the Unicat in my previous post. Beautiful machines!)

(Also, please don't think I was dissing the Unicat in my previous post. Beautiful machines!)

dzzz

™

You guys aren't talking about a 30 foot body on a frame. Your taking about unibody cars. I'm not sure you can make a comparison between a performance car and a truck. In a race car your trying to keep the wheels on the ground, not prevent damage.

But I don't really know.

I have a design for a 13 foot body on a 11 foot frame. I'll upgrade the suspension and then determine the necessary size of the wheel well. But beyond that I don't know what's right to do. At this point I'm thinking a rear pivot with the front point mounted on rubber.

But I don't really know.

I have a design for a 13 foot body on a 11 foot frame. I'll upgrade the suspension and then determine the necessary size of the wheel well. But beyond that I don't know what's right to do. At this point I'm thinking a rear pivot with the front point mounted on rubber.

Here's an example of a simple torque-free subframe that worked successfully.

Carl and Mary Hunter of Vancouver, BC, had long talked about driving around the world. Their plans were put into motion in late 2001 when they decided to join a group from the Silk Route Motorcaravan Club who were traveling across Asia.

With only a few months to acquire and outfit an overland vehicle, Carl decided to mount a Bigfoot travel trailer onto a 2000 Fuso FG 639. With the help of a local fabricator (anyone know who it was?), the travel trailer wheels and tow hitch were removed, and the trailer mounted on the Fuso

Ready for the road:

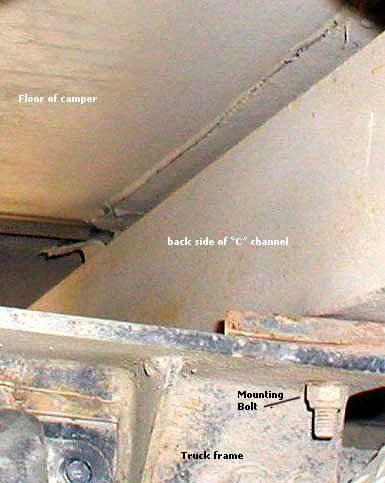

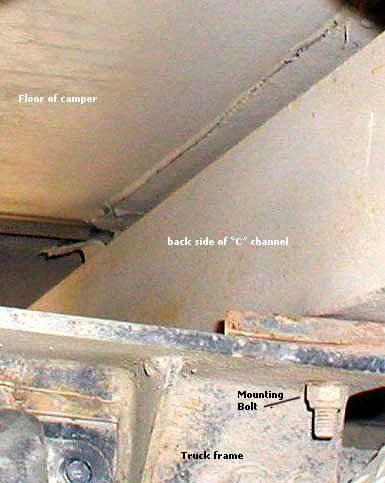

Carl knew that reducing the impact of the twisting truck chassis on the camper was needed. His fabricator made a simple three point subframe. The front mount has the pivot (the shiny bolt in this photo):

The rear mount is welded to the camper frame, and bolted to the truck frame using holes provided by the factory.

Carl's vehicle was conceived, sourced, assembled and stocked with gear in 90 days. Carl drove the vehicle across Canada and USA, shipped to Europe, and then drove across Asia in 2002.

The truck and camper were virtually trouble-free during that 6 month, 22,000 mile journey.Carl checked the pivot and mounting bolts regularly, and on just one occasion found a bolt had worked a bit loose.

Chip Haven

Carl and Mary Hunter of Vancouver, BC, had long talked about driving around the world. Their plans were put into motion in late 2001 when they decided to join a group from the Silk Route Motorcaravan Club who were traveling across Asia.

With only a few months to acquire and outfit an overland vehicle, Carl decided to mount a Bigfoot travel trailer onto a 2000 Fuso FG 639. With the help of a local fabricator (anyone know who it was?), the travel trailer wheels and tow hitch were removed, and the trailer mounted on the Fuso

Ready for the road:

Carl knew that reducing the impact of the twisting truck chassis on the camper was needed. His fabricator made a simple three point subframe. The front mount has the pivot (the shiny bolt in this photo):

The rear mount is welded to the camper frame, and bolted to the truck frame using holes provided by the factory.

Carl's vehicle was conceived, sourced, assembled and stocked with gear in 90 days. Carl drove the vehicle across Canada and USA, shipped to Europe, and then drove across Asia in 2002.

The truck and camper were virtually trouble-free during that 6 month, 22,000 mile journey.Carl checked the pivot and mounting bolts regularly, and on just one occasion found a bolt had worked a bit loose.

Chip Haven

I agree with many of the points regarding a more active suspension and a more rigid frame, the biggest issue with a long frame and the weight involved is that if the frame is not allowed to flex it increases the likleyhood of a fracture. On my F-700 I have switched out the front springs to a parabolic leaf which made a huge difference in the ride and the front axle actually moves now, the rear leafs are going to the steel bin and a complete air ride is going in, the frame is sleeved from the factory, and I will be increasing the rigidity of the frame only slightly in the suspension mounting area. I have 16 feet of frame rail from the back of the cab and a 18 foot box is going on, I am considering a lateral pivot at the front right behind the cab beacause that section of the frame is quite rigid from the factory cab mount locations and cab stiffness, and 2 -3 pivoting members extending to the rear. I also have an overhead and pass thru so I would like to keep the cab from contacting the box, I think it will work, time will tell.

jesusgatos

Explorer

I'm with you. My M109 has got some little springs under the hardware that bolts the box to the frame so that the box can pull away from the frame a little bit when the chassis flexes, but it's much more rigidly mounted than most of these pivoting setups that seem to be so popular. This particular M109 was made in 1963 and I'm sure it's seen it's fair share of use/abuse. It's held up GREAT. But the box itself weighs 4000lbs, so it's probably built a LITTLE bit stouter that most of the expedition rigs, but I'm curious to see how it the flexing will be an issue after it's all outfitted with all of the interior cabinets and whatnot. I'm guessing (hoping) it won't be a problem. If it is, I'll be re-reading this thread...I realize that this really isn't feasible or possible with a ladder frame of this length, but the very idea of designing to flex it intentionally is abhorrent to me. Designing to deal with it's undesired flex is another thing entirely.

I would think that with a box of the size usually used on trucks of this size that one could design the structure with enough torsional strength that any sort of flexible mounting method would be unnecessary. Obviously that isn't so easily done or it would have been the path long taken.

I'm with you. My M109 has got some little springs under the hardware that bolts the box to the frame so that the box can pull away from the frame a little bit when the chassis flexes,

Do you have any pictures of the spring loaded mounts?

Similar threads

- Replies

- 33

- Views

- 4K

- Replies

- 3

- Views

- 1K

- Replies

- 25

- Views

- 5K

- Replies

- 0

- Views

- 554

- Replies

- 37

- Views

- 5K