Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

pivoting frames and mounting campers

- Thread starter lehel1

- Start date

ntsqd

Heretic Car Camper

Doug, I'm not sure what I'm proposing. My mind says it can work, but I haven't wrapped myself around it well enough to explain it. If that makes any sense.Can you post an illustration or sketch of what you are proposing? I'm not clear on what you mean by shackles.

What I'm seeing is that there is a central pivot, like current practice in a 'diamond' mount, but instead of the end mounting points it would have periodic shackles placed along the length of each frame rail. I can see that the exact geometry of those shackles and their pivot points would make or break the concept. What I've not resolved is what that geometry might need to be.

Alan, do you have any postable pictures of what you built?

Mickldo

Adventurer

Mick,

Look on the first page of this thread and you'll find engineering drawings of the FG frame showing the step down section.

Doug

Thanks Doug. I knew I had seen the pic somewhere but couldn't remember where. I should have known it would have been in this thread

Mickldo

Adventurer

Doug, I'm not sure what I'm proposing. My mind says it can work, but I haven't wrapped myself around it well enough to explain it. If that makes any sense.

What I'm seeing is that there is a central pivot, like current practice in a 'diamond' mount, but instead of the end mounting points it would have periodic shackles placed along the length of each frame rail. I can see that the exact geometry of those shackles and their pivot points would make or break the concept. What I've not resolved is what that geometry might need to be.

Alan, do you have any postable pictures of what you built?

I think I have a rough idea of what you mean. I like the idea.

Maybe we need to make a scale model to check the geometry?

whatcharterboat

Supporting Sponsor, Overland Certified OC0018

Mick,

They are very close to an NPS in shape except the step is a separate section. I reckon they just cut an FE in half and rivet in the step section but I've never really been able to confirm this. The rails are 4.5mm and the step is 6mm. Of course as you know the old NPS was 6mm all the way though and they are one piece rails. Also looking forward around the shackle point of the front suspension, the rails flair out to go around the engine. Can't remember but I think the taper on the NPS is a bit further back. The new NPS is straight No taper or step.

At the very rear (around the diff) the FG tapers up too whereas the NPS steps up a little and then remains the same flange hieght. So the FG doesn't really like too much stress right on the very very back.

Have a look at the modulus drawing on Doug's site. His site is without a doubt. the best "FG Quick Reference Guide" there is. Lol.

They are very close to an NPS in shape except the step is a separate section. I reckon they just cut an FE in half and rivet in the step section but I've never really been able to confirm this. The rails are 4.5mm and the step is 6mm. Of course as you know the old NPS was 6mm all the way though and they are one piece rails. Also looking forward around the shackle point of the front suspension, the rails flair out to go around the engine. Can't remember but I think the taper on the NPS is a bit further back. The new NPS is straight No taper or step.

At the very rear (around the diff) the FG tapers up too whereas the NPS steps up a little and then remains the same flange hieght. So the FG doesn't really like too much stress right on the very very back.

Have a look at the modulus drawing on Doug's site. His site is without a doubt. the best "FG Quick Reference Guide" there is. Lol.

I do have some pic's, when I get home from Taiwan I will dig them out and post them.

Doug, I'm not sure what I'm proposing. My mind says it can work, but I haven't wrapped myself around it well enough to explain it. If that makes any sense.

What I'm seeing is that there is a central pivot, like current practice in a 'diamond' mount, but instead of the end mounting points it would have periodic shackles placed along the length of each frame rail. I can see that the exact geometry of those shackles and their pivot points would make or break the concept. What I've not resolved is what that geometry might need to be.

Alan, do you have any postable pictures of what you built?

dhackney

Expedition Leader

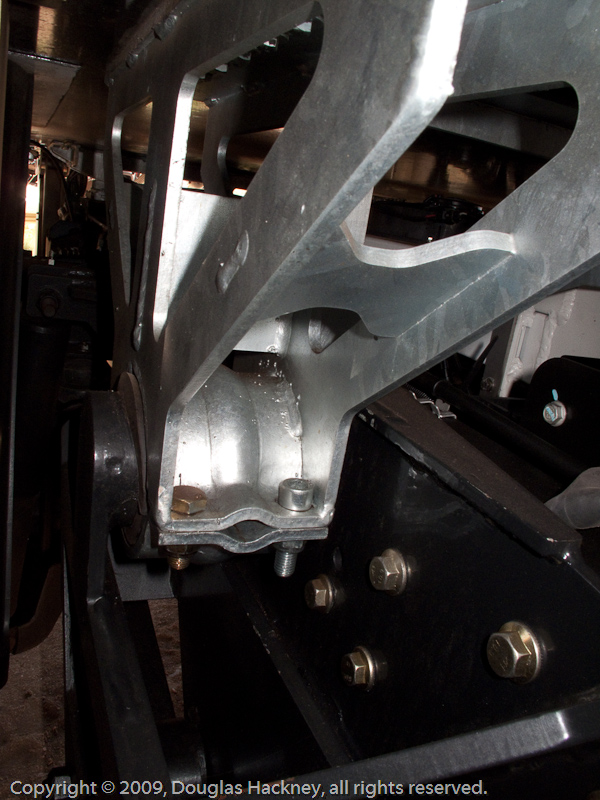

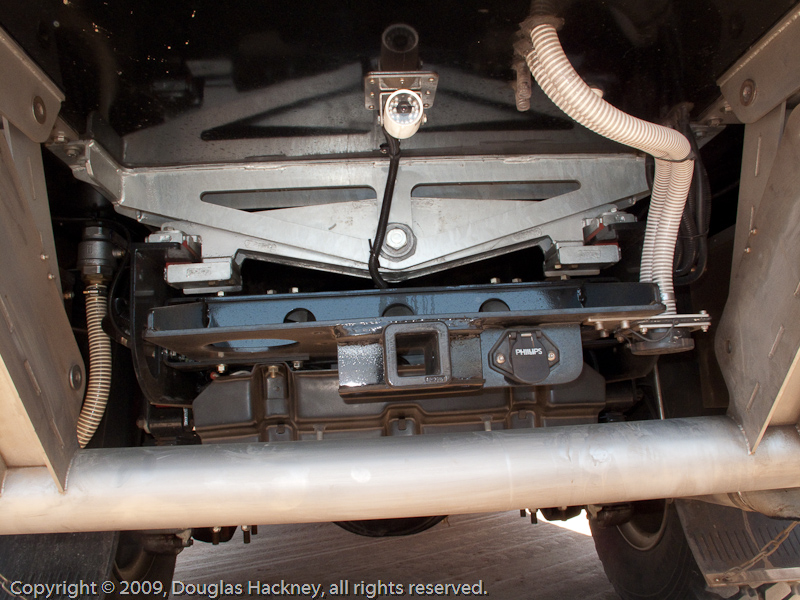

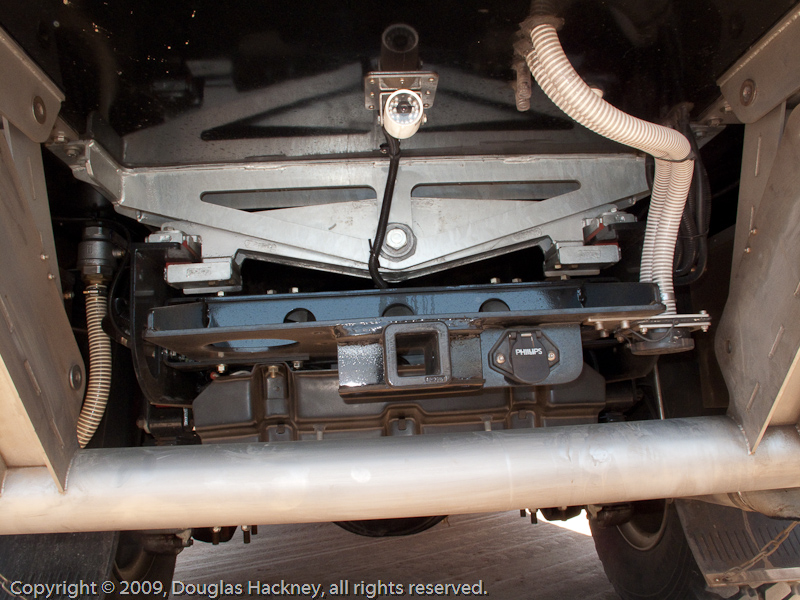

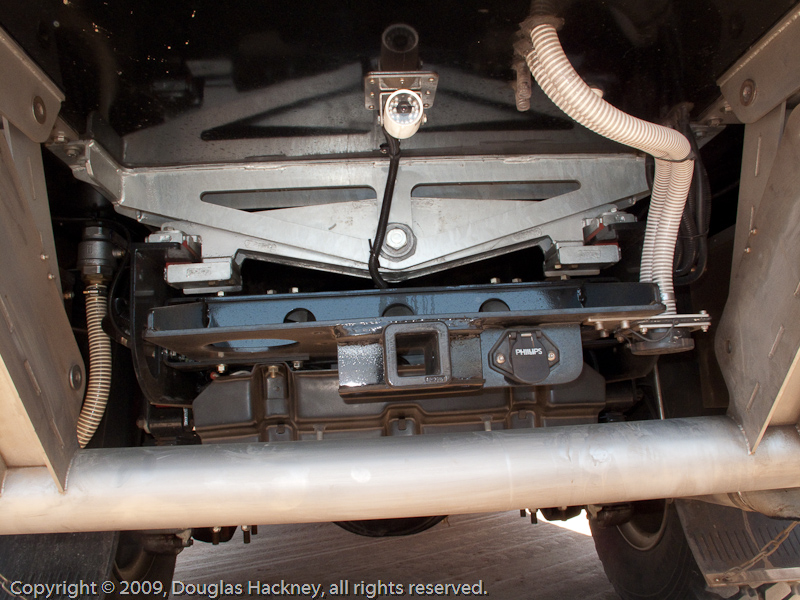

Here are some shots from the 2009 Overland Expo.

****************************************

These are from Jay Shapiro's EcoRoamer.

It uses three pieces of aluminum separated by two layers of standard rubber body mounts.

The frame on this truck was fully sleeved, so it is significantly stiffer than a stock Ford.

The big advantage of this design is that it spreads the weight of the camper box along the entire length of the frame.

**********************************************

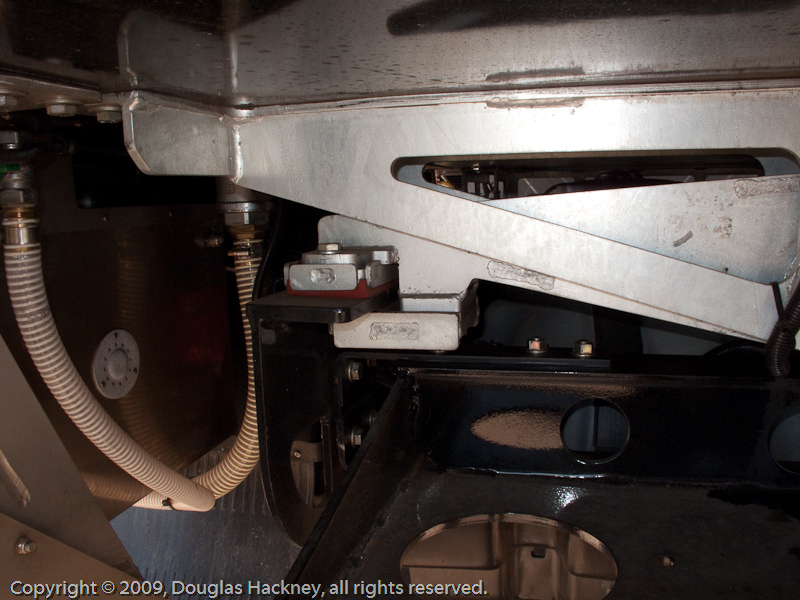

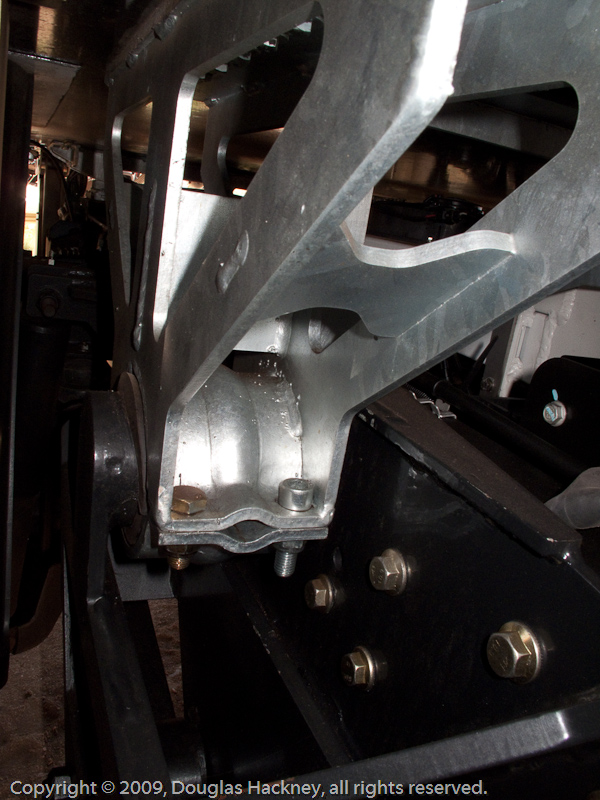

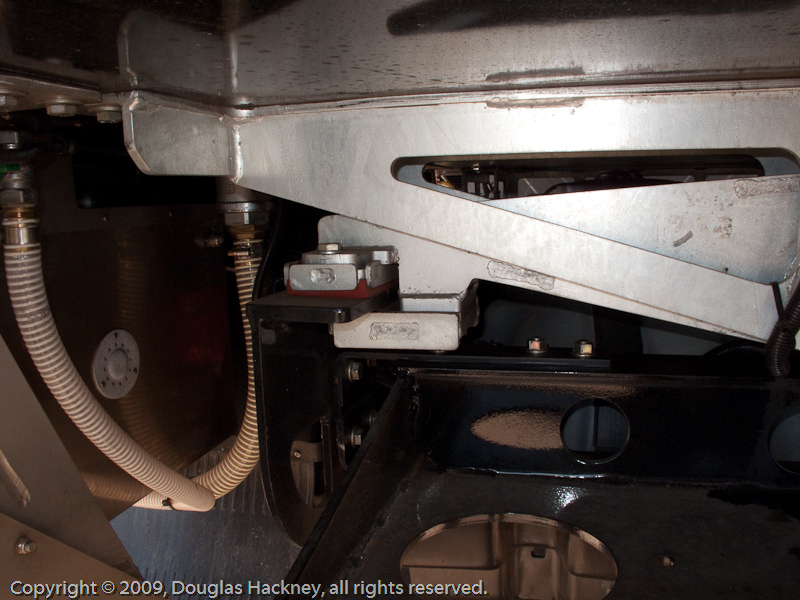

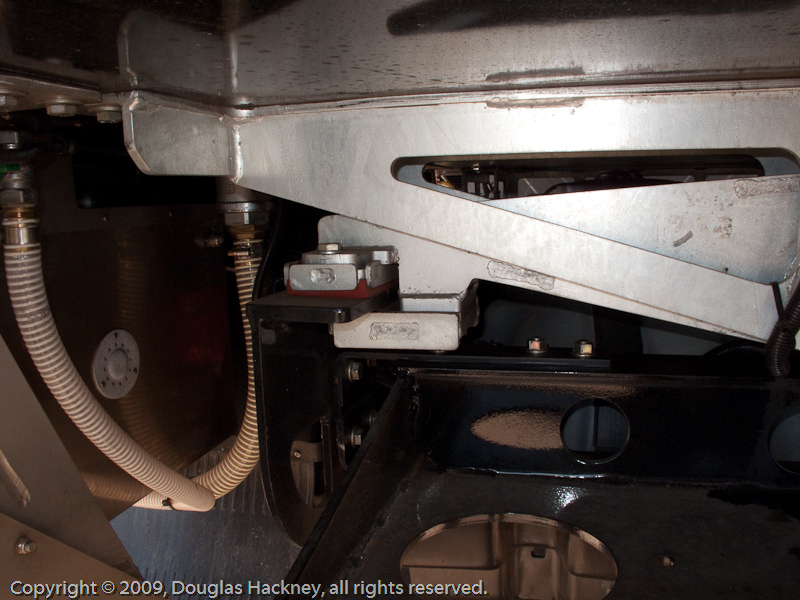

The following are from the Unicat.

This is a three point, rear pivot design.

The front mount incorporates a longitudinal pivot and the rear mount a lateral pivot.

*********************************************

****************************************

These are from Jay Shapiro's EcoRoamer.

It uses three pieces of aluminum separated by two layers of standard rubber body mounts.

The frame on this truck was fully sleeved, so it is significantly stiffer than a stock Ford.

The big advantage of this design is that it spreads the weight of the camper box along the entire length of the frame.

**********************************************

The following are from the Unicat.

This is a three point, rear pivot design.

The front mount incorporates a longitudinal pivot and the rear mount a lateral pivot.

*********************************************

Thanks Doug, great pictures. Anyone know the amount of flex in that Ford frame on the Ecoroamer compared to a Unimog or FG? Are the brackets to which the camper is bolted on the Ecoroamer welded to the frame or welded/bolted? In some pictures I can only see welds but in others there appear to be bolts.

ntsqd

Heretic Car Camper

There is something hidden in plain sight here that I find interesting. It would appear that the frame mounted half of this pivot assembly is free to translate length-wise on the frame. The lower half is not bolted or welded in place. It clamps the rail's flange between those red pads. I'd venture that the pads are urethane to damp out NVH in the box, which would mean that a large distance translation has some significant friction to over-come but a short distance distortion of the pad would be relatively easy.Here are some shots from the 2009 Overland Expo.

[hi-jack] Yikes! my 3500th post!!!![/hi-jack]

Last edited:

dhackney

Expedition Leader

[hi-jack] Yikes! my 3500th post!!!![/hi-jack]

[thread drift]And no better place for it!

Congrats!

[/thread drift]

dhackney

Expedition Leader

Thanks, Doug! I bet you were the only person

at the Overland Expo who was taking photos of the

undersides of the big vehicles. Much appreciated!

Chip Haven

Chip,

I asked Mike Van Pelt of GXV for permission before I took any shots of their mounting system. He gave me permission to shoot but asked that I not post the photos. They have street sweeper type brushes mounted on the truck to cosmetically shield the mounting system from view (it actually does look cleaner with them). The mounting system is very tall, and contributes a lot to the overall vertical height of this rig.

The GXV uses a three point system similar to the Unicat mount in the photos. I am confident Mike would be happy to answer any questions anyone has about their construction and the design of the mount. That assumption includes that the person was a true prospect for the purchase of a GXV.

There wasn't anybody around the Unicat rigs when I shot those photos to ask permission.

The Dutch DAF truck uses a four point system that looked identical to a typical Unimog 4 point design.

By far the cleanest design and execution for a mount was on Dan's Fuso that Darrin Fink built. Darrin's work reflects a high level of craftsmanship.

Doug

GXV Unimog U500 based rig. It uses a 3 point pivot system similar to the Unicat design.

1981 DAF, ex-military truck, bought with zero (0) miles on the chassis a few years ago. IIRC, it now has about 80,000. Been around the world. This truck uses a four point mounting system identical to a typical Unimog design. This truck sold at the show. I don't know the final selling price.

dhackney

Expedition Leader

Hi Doug ,

Interesting pic's, the unicat looks like great workmanship, but the ecoroamer, mmmm Iooks poor quality.

Jay's EcoRoamer reflects typical characteristics of a one-time, first-time build of a custom expedition vehicle project. There are aspects of execution on the EcoRoamer that are top level, such as the electrical systems closet. Personally, I hope his pivot system works flawlessly, since we all need an example of a system that provides payload location, frame flex and longitudinal load distribution.

The pivot systems of one-time, first time builds are often pretty crude. Ours looked good because our fabricator, Mark Johnson, is an artist level fabricator and insists his work look museum worthy. It doesn't hurt he's been building show quality race trucks for a few decades either.

On first-time, one-time builds of expedition vehicles, it's more typical to find crude, amatuer-level, design and execution of the mounting/pivot system such as on Michel Szulc Krzyzanowski's Fuso FG 140 built by Santek. I would rate Jay's EcoRoamer camper box mounting and suspension system a light year or two above MSK's Santek.

Doug

dhackney

Expedition Leader

Thanks Doug, great pictures. Anyone know the amount of flex in that Ford frame on the Ecoroamer compared to a Unimog or FG? Are the brackets to which the camper is bolted on the Ecoroamer welded to the frame or welded/bolted? In some pictures I can only see welds but in others there appear to be bolts.

I don't know the relative flex. The entire frame was sleeved with a continuous piece of L channel that covers the top flange and extends down the outer surface of the web.

All the brackets I saw were welded to the L sleeve.

Similar threads

- Replies

- 36

- Views

- 4K

- Replies

- 3

- Views

- 1K

- Replies

- 25

- Views

- 5K

- Replies

- 0

- Views

- 561

- Replies

- 37

- Views

- 5K