Here comes just what everyone wants, a vintage Four Wheel Campers FWC furnace post! For the sake of other people searching the internet for information Ive tried to include things I used as search terms when researching this, hence the odd wording in some of this post. Im the kind of person that wants to figure things out for myself and loves to take things apart and put them back together. Here comes the novel about my experience.

For starters, my furnace is working! I couldn't be more thrilled about this. I learned A LOT to get here but I didnt learn exactly what caused my furnace to start working again HAH! It required pulling the entire thing apart and putting it back together.

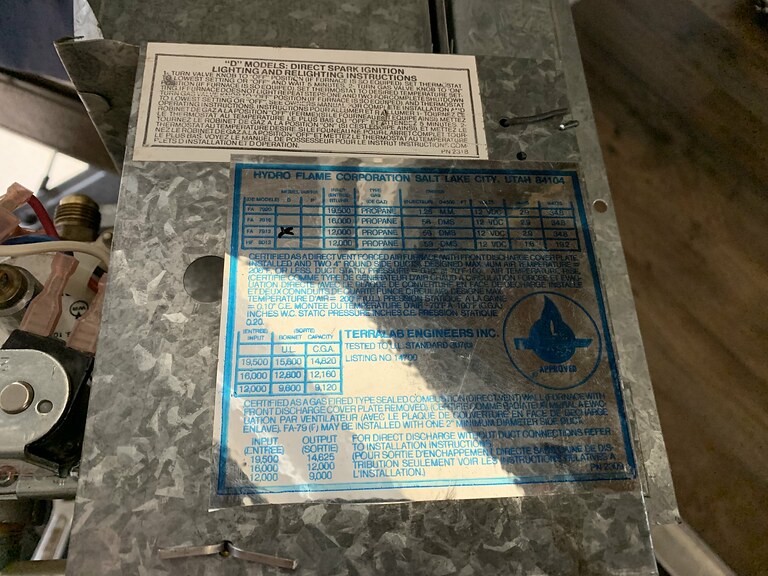

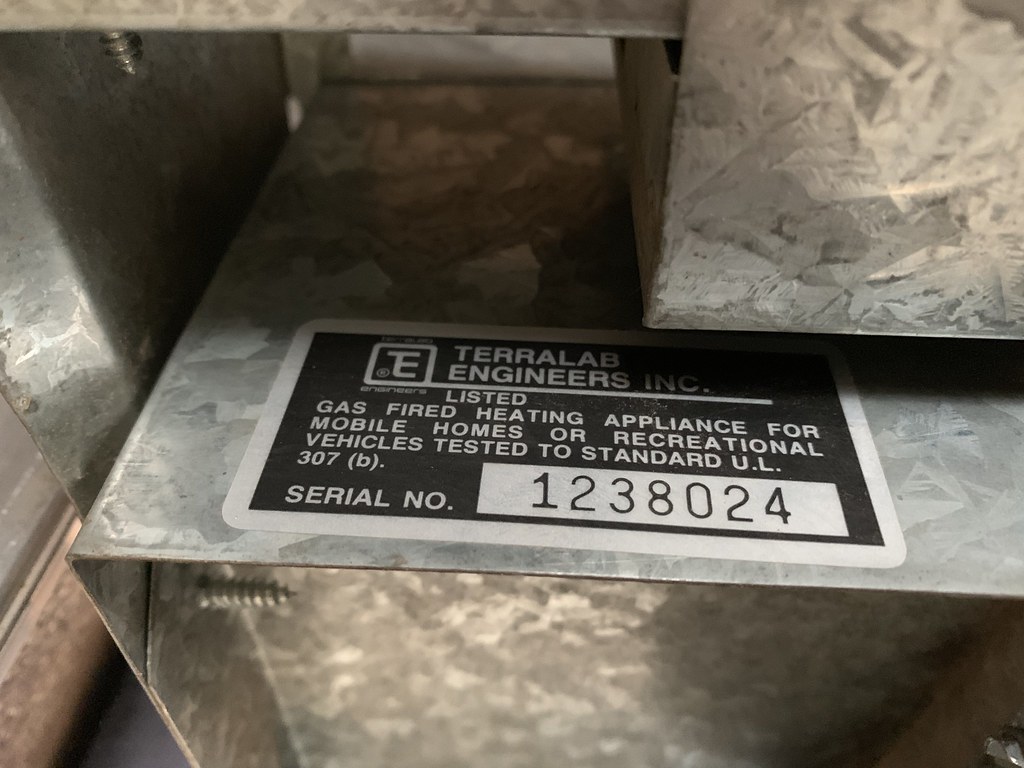

My 1986 Four Wheel Campers FWC Fleet has an Atwood Hydro Flame Hydroflame Terralab Engineers 7912 furnace.

FWC calls the furnace an Atwood, however, it does not say Atwood anywhere on the furnace, that I can find. It does say Terralab Engineers, and also Hydro Flame Corporation which apparently turned into Atwood at some point in the past. For this post I used information from numerous sources on the internet and combined a few different techniques I came across. At some point I just said F it and started doing everything to see if it would work when I put it back together.

I started tearing it apart to see if there were any bee hives, animal nests etc clogging things up. There were a few small wasp nests which I cleared out but I don't think they were causing the furnace to not light. I unhooked the propane feed line where it goes into the gas valve and turned on the propane at the tank. I could smell propane instantly but not as much as I thought I would so this lead me to think three things: the line is partially blocked, the lines don't flow as much as I expected, and maybe the line isn't flowing enough to trip the gas valve.

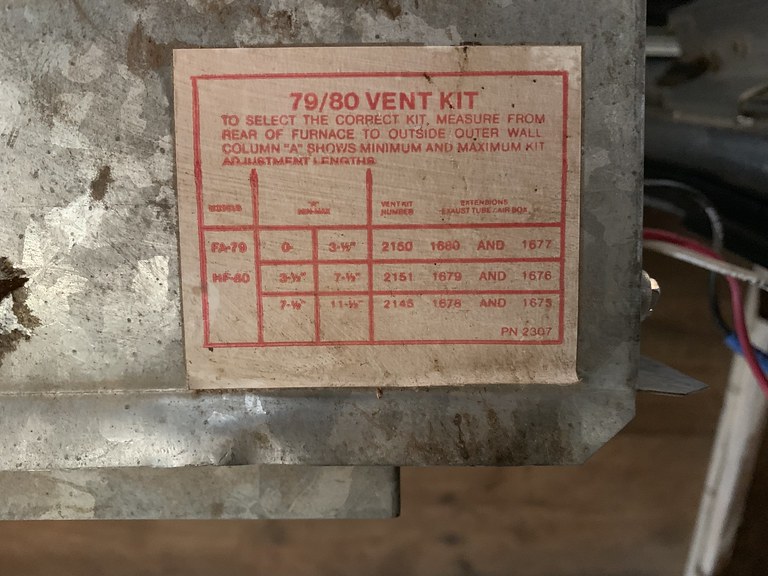

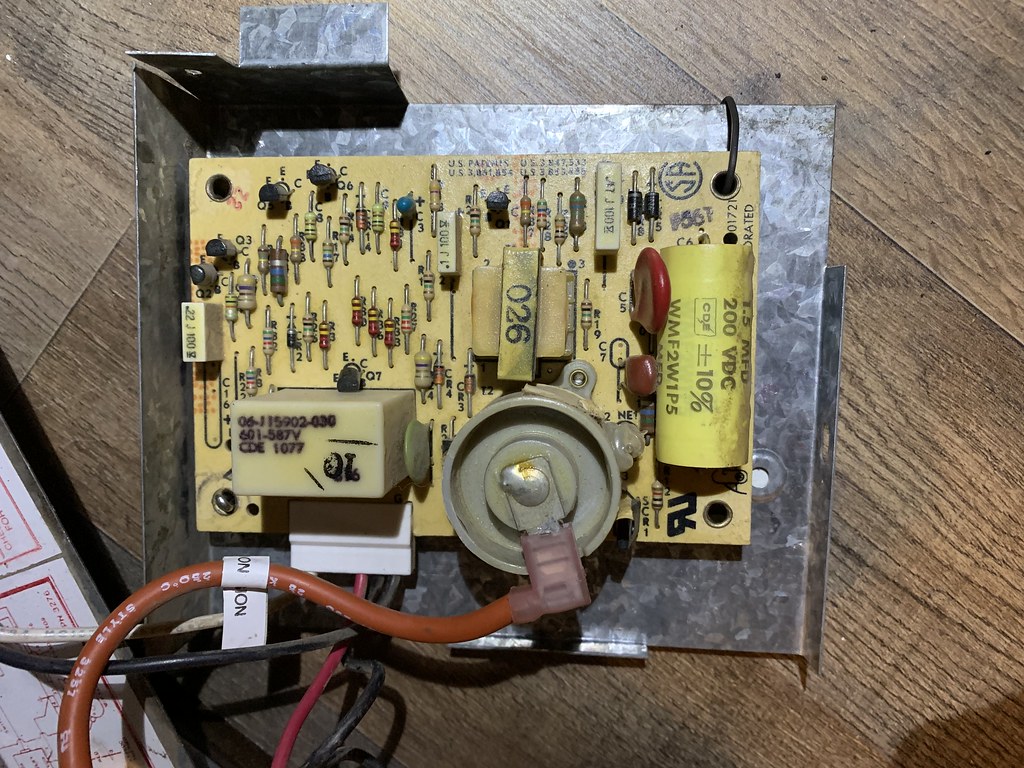

I completely stripped the furnace down. Pulled the fan cover off, pulled the fan out, flicked the sail switch a couple times to see if its action felt ok and it did, pulled the ignitor circuit board off, removed all the misc. sheet metal shields and panels, removed the gas valve assembly, removed the magnets and spun the shafts going into the gas valve, adjusted the tines (electrodes?) on the ignitor to meet the factory 1/8th inch spark gap(one of the 3 was farther than that which could have been an issue), removed what I think is called the "circuit breaker" on the wiring schematic but Im not sure, cleaned everything, read all the labels, took pictures of everything and ultimately blew compressed air through the propane lines.

With the propane off and a house battery hooked up I busted out the old multi meter and started checking things. House battery had 12.6 volts, so low voltage isn't the issue. The sail switch, relay, limit switch are seeing 11.6-8. The ignitor and gas valve are seeing 11.5-6 but only when attempting to ignite. They were seeing zero or .0x when the fan was running but not attempting to ignite. I turned the thermostat to "on" to see what would happen. The interesting thing is the ignitor was seeing voltage and attempting to ignite even when the power and ground were disconnected from the ignition probe itself. The + cable for the ignitor was popping even when it was simply dangling in the air, the ground to the ignitor was not hooked up. Slightly scary.

Since scary electrical things were happening, what did I decide to do? Blow into the gas valve when it was hooked up to power to see if it would trip!!! Sure enough, blowing into the gas valve when it was hooked up resulted in the valve popping open and the ignitor attempting to ignite, instantly, the fan had been running and the ignitor had stopped after its normal 3 cycle attempts to ignite. This was the first time the gas valve has opened that I am aware of. It made a very clear audible click/thunk noise I had not previously heard. Now Im experiencing two thoughts, gas wasn't flowing enough to trip the valve or removing and reassembling the parts on the valve assembly (namely the magnets on the shafts that open/close the valve) was enough to kick the valve back into working condition.

Since I heard the gas valve solenoid seeming to work I decided to clean up and reassemble everything. Sure enough it fired up on the very first attempt. I didnt even have to purge the air out of the lines by running the stove. I guess this isn't a surprise since propane is heavier than air and from the tank to the gas valve is all downhill. Im slightly perplexed and its my own fault for trying multiple "solutions" at the same time instead of doing one at a time and hooking it all back up to see if it would work. I didn't have the patience for that today so Im ecstatic that it works now. Hopefully it works in the morning and this wasn't all a dream hah.

Furnace model information

Ignitor circuit board

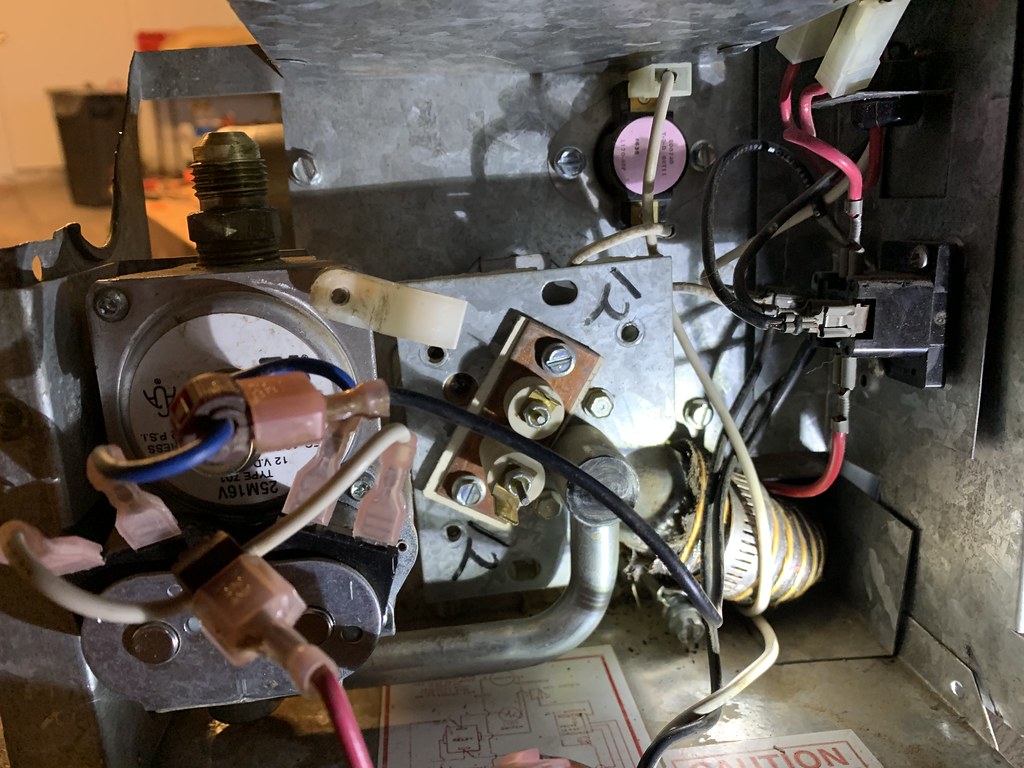

Gas inlet on the upper left, gas valve on the left, ignitor in the center, relay on the right, "limit switch" (which seems to be simply a temp sensor) upper center with the pink round sticker on it, bottom right is the black/yellow exhaust pipe (make SURE this is well connected, its what exhausts the unspent gaseous fumes to the back of the camper, you don't want them getting into the furnace with electronics firing or into the camper itself.)

Another picture of the same assembly as above. The upper right corner where two red wires go into two white plastic connectors is what I believe to be the circuit breaker. See pictures below.

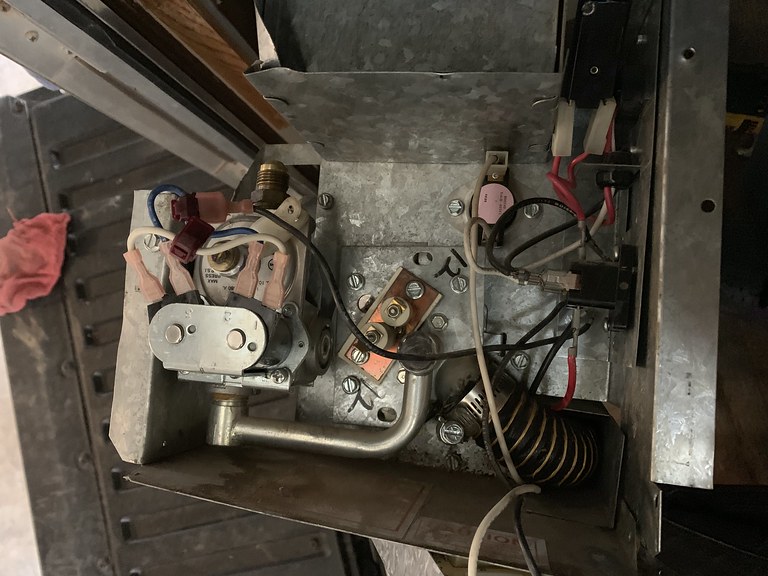

The right side of the circuit breaker is a button that can be pushed in. It doesnt click, it doesnt have another position where it stops, it simply pushes in and spring loaded returns to its original position. It has an S or a 5 or 6 stamped into the end of the button. Pressing it didnt seem to change anything during my attempts to fire the furnace, before during or after the ignition process. Also, its located in a place that is completely unreachable when the furnace is bolted into its normal resting place. When I reassembled the furnace I relocated this switch to a spot near the ignition circuit board that is accessible when the furnace is mounted in place.

Furnace assembly with fan/shroud removed.

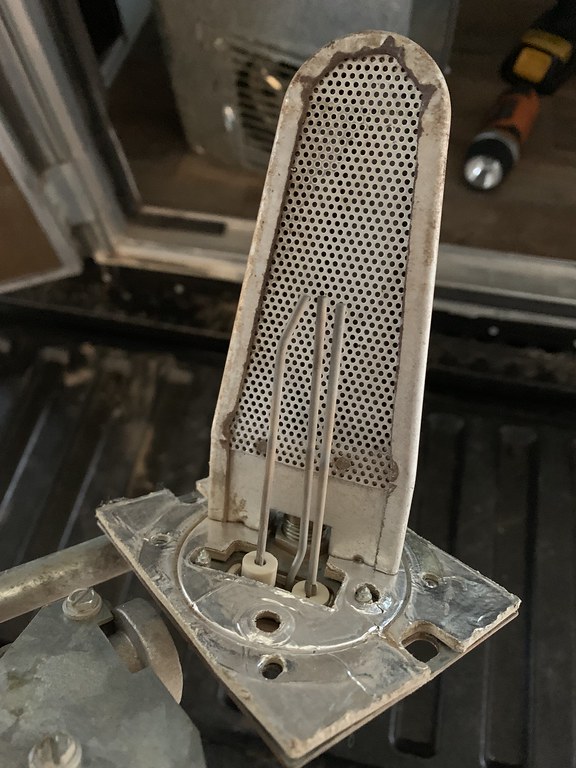

Burner assembly and electrodes, before I adjusted them. Hard to tell the depth from this picture but the tine on the right was 1/4" + away from the other two. I adjusted them so all 3 were 1/8" from each other.

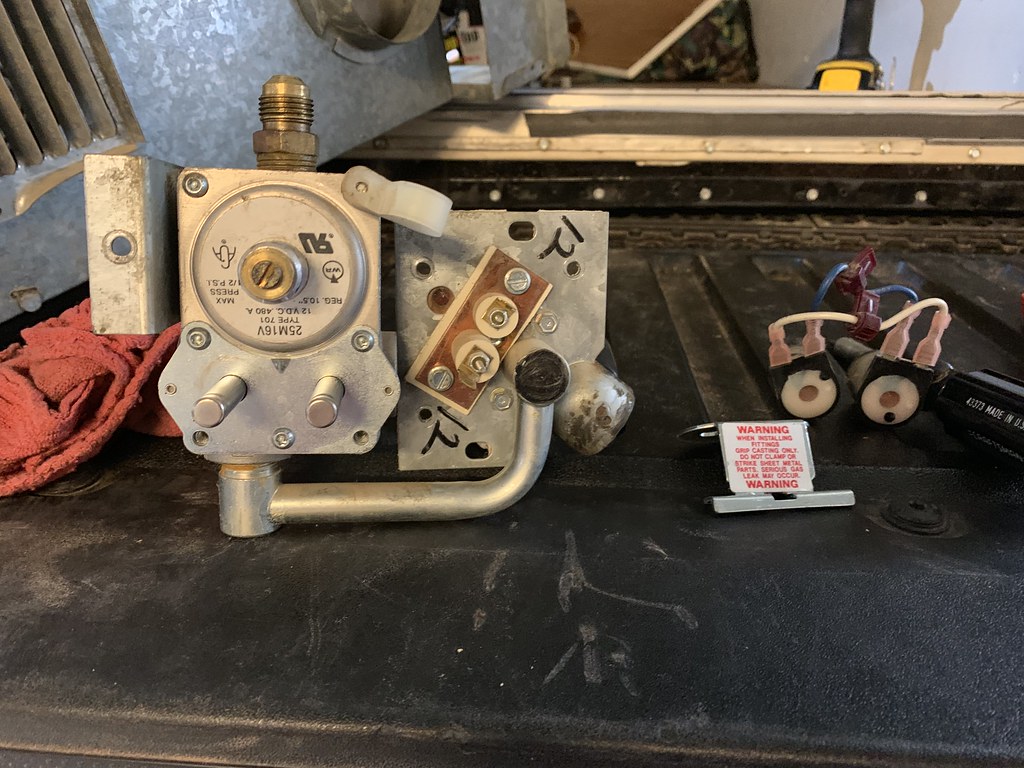

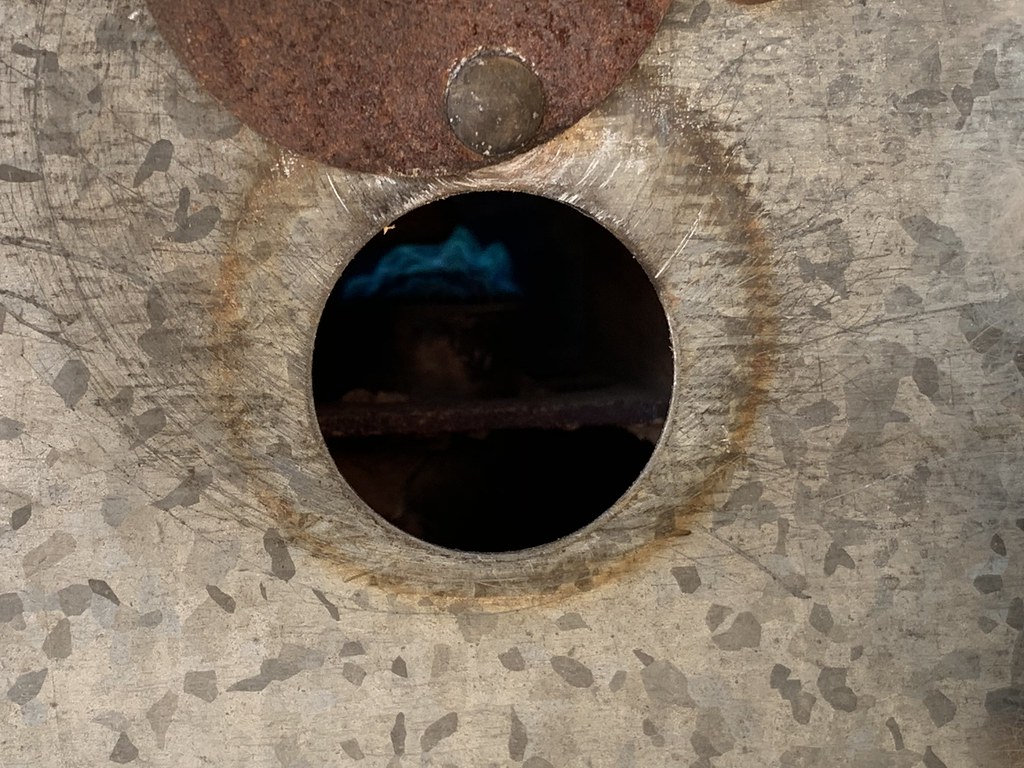

Gas valve assembly intact but with the + and - removed from the electrodes.

Gas valve assembly partially disassembled. Magnetic "switches?" removed from the shafts that open/close the valve/s...I think. Going pretty far out on a guessing limb here. You can see the "switches" or "actuators" with their jumpers still connected on the right. Everything was very clean, the shafts spin smoothly in the assembly, the switches slid on and off the shafts with ease. Is it possible the shafts were simply stuck from years of sitting unused and spinning them by hand caused them to work again? Maybe. Similar to how whacking a starter causes it to work when it has dead spots? Maybe. Am I crazy and making things up? Maybe.