Get your tickets to THE BIG THING 2026!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project Hundy Build Thread - 2000 UZJ100 Land Cruiser

- Thread starter cruiseroutfit

- Start date

cruiseroutfit

Well-known member

thanks it does but in regards to budget and items to do; is there anything that maybe was not used or was not worth the expense and could have gone without is the big question. thanks again for being open to questions.

Another great question, while I'll answer I think asking Greg or Scott (perhaps in another year after the entire E7 voyage is done) would net far better intel as they are far, far more intimately in tune with the rigs. On top of that, I've experienced them in North America and Russia, two totally different environs but similar as far as vehicle needs. Some of their build components not utilized there may very well come in handy or be deemed mandatory when in Australia or Africa for example. So as for my answer, the on-board cab heater systems, while we used them for comfort during cold Siberia nights, other nights we did not and survived just fine. But come Antarctica I suspect they team will deem them borderline mandatory for a good nights rest

cruiseroutfit

Well-known member

Death Star Build Part# 3: Parts Acquisition & Install/Build Planning

The collection of build parts lined up & ready for install

So with a build plan set and my list of needed parts refined, it was time to get all these parts coming and set them aside for the build time. I didn't have a set date for the build but I didn't want to pass up an opportunity because I didn't have all of the crucial parts on hand and ready to go. Time to get on the ringer.

The ARB parts were the easiest for me to line up, as we get weekly/bi-weekly stock orders via truck freight from ARB. Over the past few months I was able to sneak a bumper on the order here and a side rail kit there and before long we had all of the big components in house. The smaller items such as the ARB CKMA12 compressor and snorkel I could pull out of inventory (yes, even I have to pay for them ) and set them aside for the build. Over the course of 4 months I had a front bumper, rear bumper, snorkel, slider-steps, and side rails - all tucked away on the top level of some pallet racking in the shop.

) and set them aside for the build. Over the course of 4 months I had a front bumper, rear bumper, snorkel, slider-steps, and side rails - all tucked away on the top level of some pallet racking in the shop.

ARB Stockorder, it's like Christmas over and over

My next call was to Paul at Equipt Expedition Outfitters. Eezi-Awn was ready to launch their new low-profile K9 roof rack lineup, and Paul had some on a container headed for the US, so I made sure my name was on one. Paul is also the distributor for the National Luna product line here in the US. Cruiser Outfitters stocks the National Luna Dual Battery kit, so I was sure to have a spare on the shelf that I could use for the build. Not only did Paul make sure my name was on an incoming rack, he was quick to say "what else can I do to help with the build", and if you know Paul you're not surprised. Paul has been a long-time friend, a long-time customer, and a long-time supplier of ours. Paul was a pioneer with the 100 Series platform and has put hundreds of thousands of miles on his well equipt (pun intended) 1998 model. I've had the opportunity to help Pal outfit his 100 over the years as well as travel with Paul on many of his adventures. It's 100% fair to say his 100 Series capability, reliability, and functionality was a major driving force in my adoption of the platform. (Check out his build thread here)

Paul May's well build 1998 UZJ100

Armor Coatings was really a shining star for me. Utah has a bunch of good powder-coaters, and I've had fair results from a few different ones, but the guys at Armor really stepped up the game in quality and timing. In just a couple of days I had powder-coated factory LC wheels, lug-nuts (which required them to make a custom fixture), roof rack mounts, step deck plates, and the rear bumper top plate. This wasn't a huge order for a production-capable power-coating facility, but still they treated me like their only job. I've since been back with a handful of other small jobs for my FJ40, and jobs here in the shop, and each time the results are the same: fast, quality and affordable... three words that don't generally get used in the same sentence.

OE 16" wheels powdercoated by Armor Coatings

Christo Slee of Slee Offroad lined me up with a good chunk of the parts I needed for the build. With a 5 minute phone call I had Slee's dual battery tray and full-suite skid plate system on the way. Christo is a pioneer in specialty components for the 100 Series platform so when it came time to outfit my own, the choice was a no-brainer. I quickly outlined our build plan and the idea to accomplish all of this in a weekend. Christo replied with a joking "good luck, my guys would hate me" and some well wishes. He made sure they had the parts in stock and let me know they would ship the next day, something you can count on when you hear that from Christo or Ben. Along with their incoming skids and battery kit, I had the Slee diff drop kit in stock and made sure to set one aside for the build. My suspension needs were now satisfied, my armor needs were now satisfied and my dual battery system was only waiting on the batteries themselves.

Slee skid plate system (Photo courtesy of Slee Off Road)

Tires are often one of the more emotional build decisions one is faced with. There are so many brands, even more styles and sizes, and most of all, opinions. I had previously decided upon the BFG All-Terrain in the 295/75R16 size, and now it was time to pony up. I called my tire guy Jared, at Big-O Tires in Sandy, not far from our shop. I'm a big advocate of developing a working relationship with your local tire guy, and Jared is my tire guy. Whether it's an alignment on a customer's freshly lifted Tacoma or a last-minute tire balance on my FJ40 before a trip to the desert, Jared and his crew always take care of me. We started with some loose factory 16" wheels and tires I picked up from some local Cruiserheads (thanks Corey & Cameron). They stripped the old tires and we got the wheels and lugnuts over to Armor Coatings. The next day the wheel and lugnut powder-coating was complete, the new BFG's were on the shelf at Big-O, and we just had to get them both in the same place for mounting and balancing. All too easy.

All mounted & balanced @ Big-O, Ready for the install

I had intended to order the winch through one of my regular vendor channels; however, I stumbled across a great deal through a local private party seller who had a new-in-box Warn VR10000 just a few miles away. I'm a fan of any winch, so long as it has a "W" on the control box Now I know there are some other great options on the market, we've installed about one of every reputable winch on the market in the shop, but having run Warns on all my previous rigs, I wasn't willing to hamper what has proven to be a near spotless track record. I've actually had two winch failures, one on my FJ40 and one on my first Tacoma. Neither failed to complete the recovery, neither left me stranded, and above all, neither cost me a penny for the repair due to Warn's lifetime warranty through Six States, our local Warn authorized winch repair facility here in town. Anything can break if taxed hard enough and often the merit of a product isn't if whether it breaks or not, but how it is dealt with after. For that reason I had no reason to look elsewhere with this new build. The VR Series is a more recent 'Value' offering in the US market, my experience thus far was all positive with the series, easy answer.

Now I know there are some other great options on the market, we've installed about one of every reputable winch on the market in the shop, but having run Warns on all my previous rigs, I wasn't willing to hamper what has proven to be a near spotless track record. I've actually had two winch failures, one on my FJ40 and one on my first Tacoma. Neither failed to complete the recovery, neither left me stranded, and above all, neither cost me a penny for the repair due to Warn's lifetime warranty through Six States, our local Warn authorized winch repair facility here in town. Anything can break if taxed hard enough and often the merit of a product isn't if whether it breaks or not, but how it is dealt with after. For that reason I had no reason to look elsewhere with this new build. The VR Series is a more recent 'Value' offering in the US market, my experience thus far was all positive with the series, easy answer.

Warn VR10,000 awaiting install in the ARB Winchbar

The Helton Hot Shower was another 'off-the-shelf' item. As I mentioned in the previous installment I opted for the Hot Water unit, which offers hotter water and more flexible uses in the future. The full setup consists of the Helton hot water heat exchanger, the heat exchanger mounting clamps, the bumper bracket, and the 12V shower pump/head. In addition I needed to source coolant hose to tie into the factory cooling system and the 1/2" fresh water hose, which can be found at a good auto parts or hardware store. In my search I stumbled across red and blue 1/2" options from a local hose supplier; they are rated for the appropriate temps, safe for use with potable water, and the red and blue color coding are welcome additions as they make for a tidy install. We will likely start adding the red/blue hose to our Helton kit offerings, or at least offer the hose by the foot for shower customers. The coolant hoses are a little more application-specific and more than that they are really specific to where/how you mount your exchanger. Because I wasn't 100% sure how everything was going to lay out under the hood with the dual batteries, compressor, auxiliary fuse block, etc., I opted to make the coolant hose components an on-the-fly parts need, easy enough to source during our build at the local auto parts stores.

Helton Hot Shower Kit

Batteries are seemingly as emotional a choice as tires, well almost. Browse internet forums and you'll find opinions based in every direction, and while I think there is much to be gained from the opinions of others, in some cases the momentum of love or hate can overwhelm the reality. I've been using Optima batteries in my FJ40 for nearly 12 years, never had one fail, never even had one go dead without good cause, they have just worked and worked. About 5 years ago I decided to replace them before a big trip just as a preventive measure, and the old one is now in my forklift, where it works fine as long as nobody leaves the key on . Along with Optima, I've had decent luck with the Odyssey (or their re-badege options) batteries. However, I literally had to replace the two Odysseys in my Tacoma (4 years old, just out of warranty) the same week as I was buying batteries for the 100 Series build. I hate to say it but the emotions got to me and I went back to the Optima. I chose a red-top for the starting battery and regular circuits and a yellow-top for my auxiliary battery, which will also run my secondary power system (Blue Sea Fuse Block). I sourced the batteries from our local Optima wholesaler, Battery Systems in Salt Lake City. The National Luna Dual battery kit comes with supplied connections, battery terminals and battery cable; however, I opted for a slightly larger battery cable gauge and thus my connectors all needed to be up-sized as well. S&H Terminal is my go-to for electrical supplies and specialty hardware, they specialize in bulk but you can buy small quantities as well. They stock battery cable (both black and red) in all major gauge sizes and you can purchase it by the foot. I keep a drawer full of battery cable build supplies in the shop, all sourced from S&H.

. Along with Optima, I've had decent luck with the Odyssey (or their re-badege options) batteries. However, I literally had to replace the two Odysseys in my Tacoma (4 years old, just out of warranty) the same week as I was buying batteries for the 100 Series build. I hate to say it but the emotions got to me and I went back to the Optima. I chose a red-top for the starting battery and regular circuits and a yellow-top for my auxiliary battery, which will also run my secondary power system (Blue Sea Fuse Block). I sourced the batteries from our local Optima wholesaler, Battery Systems in Salt Lake City. The National Luna Dual battery kit comes with supplied connections, battery terminals and battery cable; however, I opted for a slightly larger battery cable gauge and thus my connectors all needed to be up-sized as well. S&H Terminal is my go-to for electrical supplies and specialty hardware, they specialize in bulk but you can buy small quantities as well. They stock battery cable (both black and red) in all major gauge sizes and you can purchase it by the foot. I keep a drawer full of battery cable build supplies in the shop, all sourced from S&H.

Battery Cable Parts Drawer @ Cruiser Outfitters

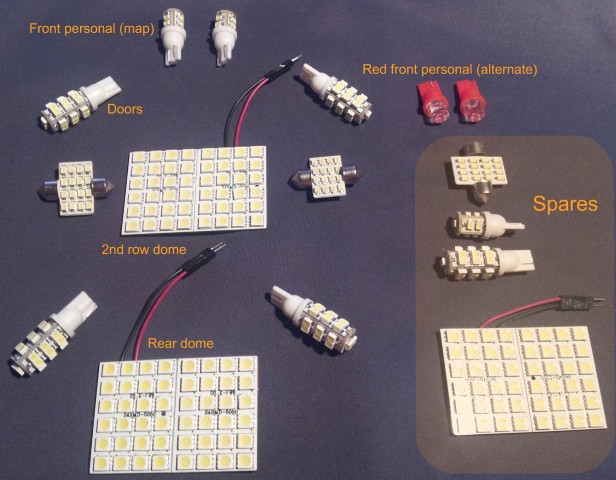

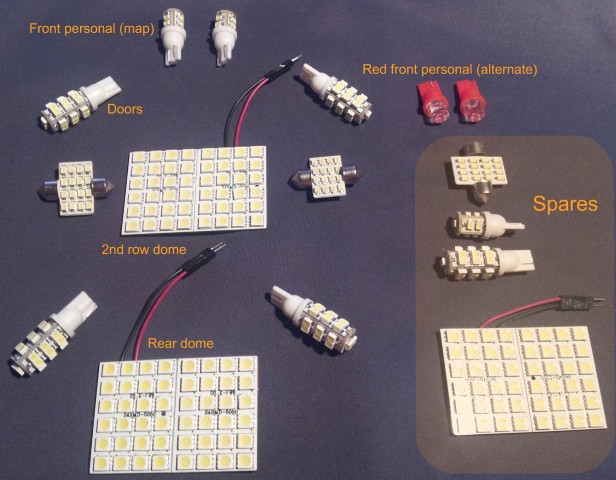

I placed a last minute order with Paul at PFran LED's Lighting for his 100 Series LED light kit. Paul was out for a few days (his wife was in the hospital) but he was quick to respond and in just a few days I had his well-assembled kit ready for the install. The kit replaces all of the standard interior bulbs with high-power LED inserts and also includes a few spares just in case you have a failure down the road. I was excited to shed some light on the interior (pun intended).

PFran LED kit tailored for the 100 Series Land Cruiser (Photo Courtesy of pfranleds.com)

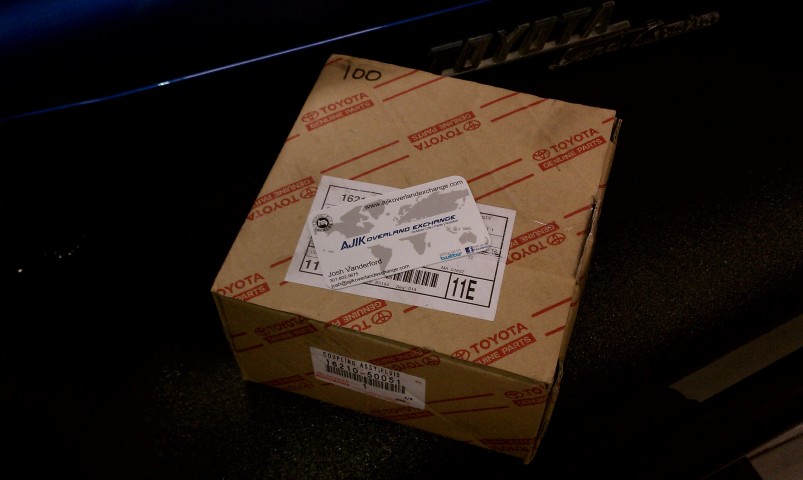

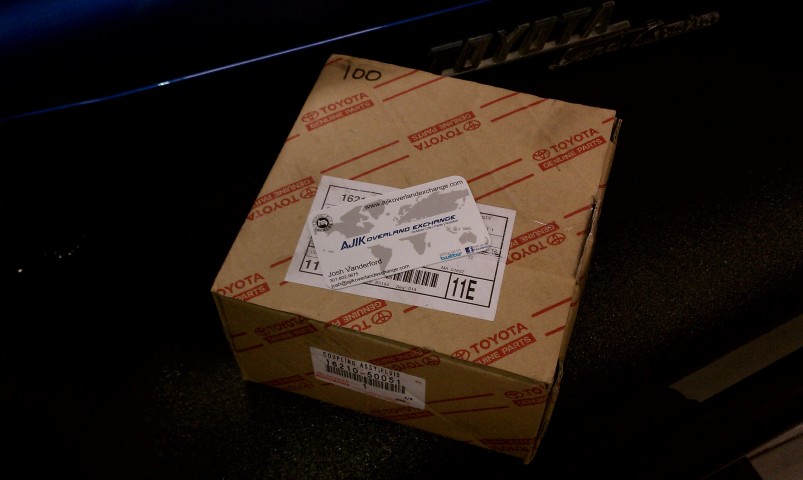

Josh Vanderford from Ajik Overland Exchangehelped us out with the new to the market Landtank modified fan clutch. The fan clutch starts as an brand new OEM fan clutch and is specially modified using a high quality 15,000 centistoke oil. This thicker oil ensures lower engine temperatures, vital for keeping the 2UZ-FE cool with the additional loads and type of uses this rig will see. Additionally, the modified fan clutch offers better air conditioner performance but pulling more air through the AC condenser. I'd advise anyone building a 'heavy hundy' to consider the upgrade, just a phone call away.

Landtank modified 100 Series fan clutch from Ajik Overland

Last but not least was to make sure I had all of the various electrical components ready to go. Besides generic wiring supplies such as bulk wire, relays, heat-shrink, etc., I would also need a fuse block, 12V outlets, USB outlets, and a fridge outlet for the back. I opted for my standard choices: a Blue Sea Fuse block assembly, Waytek Wire & RaElCo for my wire, connector and heat shrink needs, and Will at Sierra Expeditions hooked me up with a couple of the new-to-the-market Blue Sea USB outlets that he had just got in stock.

Wiring Parts Drawer @ Cruiser Outfitters

Where can you buy all (most ) these parts? Cruiser Outfitters of course! We stock the majority of these parts and can have the rest of them in short order. Wanting to do a similar build on your Toyota? Give us a ring and lets discuss it, we've specialize in fast service, and while this build was rather accelerated we have done similar builds for customers in under a week. We don't retail many of the parts used in this build, there just isn't enough demand for it but we are happy to install it as part of a comprehensive outfitting of your vehicle.

) these parts? Cruiser Outfitters of course! We stock the majority of these parts and can have the rest of them in short order. Wanting to do a similar build on your Toyota? Give us a ring and lets discuss it, we've specialize in fast service, and while this build was rather accelerated we have done similar builds for customers in under a week. We don't retail many of the parts used in this build, there just isn't enough demand for it but we are happy to install it as part of a comprehensive outfitting of your vehicle.

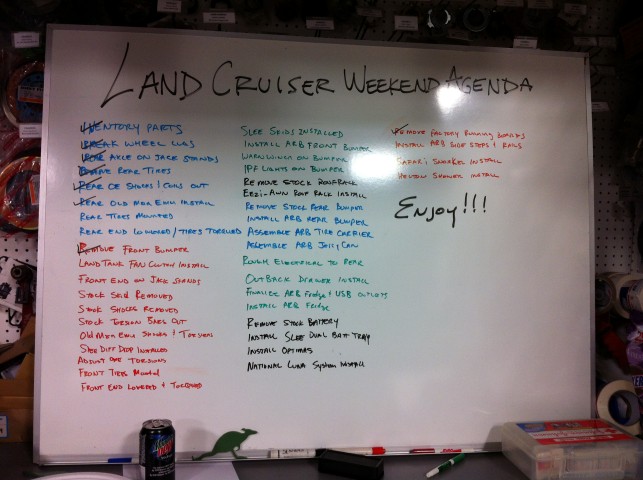

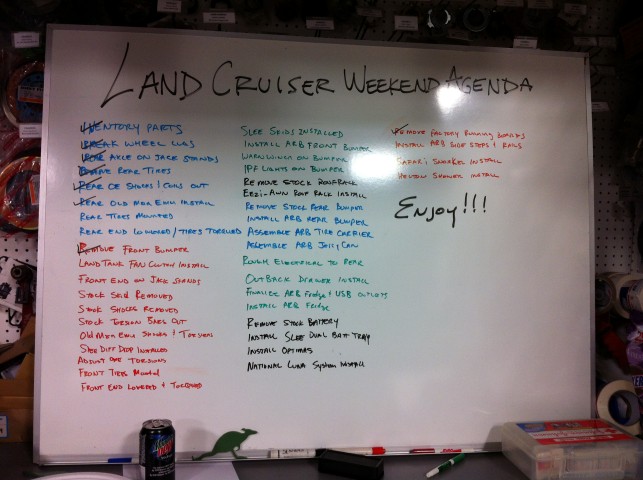

Now onto the planning, this is where I really geek out. I worked to develop a list of nearly 200 tasks that would need to be completed during the build, some dependent on other items, and some have dependents waiting on completion. With the list developed I was able to build a Gantt chart which visually dictated the order of operation that would need to happen for all of the components to make their way on the vehicle. While this might be a little over the top for some, I think it's a wise way to prioritize your limited spare time whether you plan to knock out the build in a short time period (like a weekend ) or over the course of several months or a year.

) or over the course of several months or a year.

The weekend agenda, already knocked off a few items by the time a photo was snapped

With the Gantt chart refined and finalized, I tuned the project down to ~50 major project task headings and transferred them to the dry erase board in the shop.

Next Up: The Build

The collection of build parts lined up & ready for install

So with a build plan set and my list of needed parts refined, it was time to get all these parts coming and set them aside for the build time. I didn't have a set date for the build but I didn't want to pass up an opportunity because I didn't have all of the crucial parts on hand and ready to go. Time to get on the ringer.

The ARB parts were the easiest for me to line up, as we get weekly/bi-weekly stock orders via truck freight from ARB. Over the past few months I was able to sneak a bumper on the order here and a side rail kit there and before long we had all of the big components in house. The smaller items such as the ARB CKMA12 compressor and snorkel I could pull out of inventory (yes, even I have to pay for them

ARB Stockorder, it's like Christmas over and over

My next call was to Paul at Equipt Expedition Outfitters. Eezi-Awn was ready to launch their new low-profile K9 roof rack lineup, and Paul had some on a container headed for the US, so I made sure my name was on one. Paul is also the distributor for the National Luna product line here in the US. Cruiser Outfitters stocks the National Luna Dual Battery kit, so I was sure to have a spare on the shelf that I could use for the build. Not only did Paul make sure my name was on an incoming rack, he was quick to say "what else can I do to help with the build", and if you know Paul you're not surprised. Paul has been a long-time friend, a long-time customer, and a long-time supplier of ours. Paul was a pioneer with the 100 Series platform and has put hundreds of thousands of miles on his well equipt (pun intended) 1998 model. I've had the opportunity to help Pal outfit his 100 over the years as well as travel with Paul on many of his adventures. It's 100% fair to say his 100 Series capability, reliability, and functionality was a major driving force in my adoption of the platform. (Check out his build thread here)

Paul May's well build 1998 UZJ100

Armor Coatings was really a shining star for me. Utah has a bunch of good powder-coaters, and I've had fair results from a few different ones, but the guys at Armor really stepped up the game in quality and timing. In just a couple of days I had powder-coated factory LC wheels, lug-nuts (which required them to make a custom fixture), roof rack mounts, step deck plates, and the rear bumper top plate. This wasn't a huge order for a production-capable power-coating facility, but still they treated me like their only job. I've since been back with a handful of other small jobs for my FJ40, and jobs here in the shop, and each time the results are the same: fast, quality and affordable... three words that don't generally get used in the same sentence.

OE 16" wheels powdercoated by Armor Coatings

Christo Slee of Slee Offroad lined me up with a good chunk of the parts I needed for the build. With a 5 minute phone call I had Slee's dual battery tray and full-suite skid plate system on the way. Christo is a pioneer in specialty components for the 100 Series platform so when it came time to outfit my own, the choice was a no-brainer. I quickly outlined our build plan and the idea to accomplish all of this in a weekend. Christo replied with a joking "good luck, my guys would hate me" and some well wishes. He made sure they had the parts in stock and let me know they would ship the next day, something you can count on when you hear that from Christo or Ben. Along with their incoming skids and battery kit, I had the Slee diff drop kit in stock and made sure to set one aside for the build. My suspension needs were now satisfied, my armor needs were now satisfied and my dual battery system was only waiting on the batteries themselves.

Slee skid plate system (Photo courtesy of Slee Off Road)

Tires are often one of the more emotional build decisions one is faced with. There are so many brands, even more styles and sizes, and most of all, opinions. I had previously decided upon the BFG All-Terrain in the 295/75R16 size, and now it was time to pony up. I called my tire guy Jared, at Big-O Tires in Sandy, not far from our shop. I'm a big advocate of developing a working relationship with your local tire guy, and Jared is my tire guy. Whether it's an alignment on a customer's freshly lifted Tacoma or a last-minute tire balance on my FJ40 before a trip to the desert, Jared and his crew always take care of me. We started with some loose factory 16" wheels and tires I picked up from some local Cruiserheads (thanks Corey & Cameron). They stripped the old tires and we got the wheels and lugnuts over to Armor Coatings. The next day the wheel and lugnut powder-coating was complete, the new BFG's were on the shelf at Big-O, and we just had to get them both in the same place for mounting and balancing. All too easy.

All mounted & balanced @ Big-O, Ready for the install

I had intended to order the winch through one of my regular vendor channels; however, I stumbled across a great deal through a local private party seller who had a new-in-box Warn VR10000 just a few miles away. I'm a fan of any winch, so long as it has a "W" on the control box

Warn VR10,000 awaiting install in the ARB Winchbar

The Helton Hot Shower was another 'off-the-shelf' item. As I mentioned in the previous installment I opted for the Hot Water unit, which offers hotter water and more flexible uses in the future. The full setup consists of the Helton hot water heat exchanger, the heat exchanger mounting clamps, the bumper bracket, and the 12V shower pump/head. In addition I needed to source coolant hose to tie into the factory cooling system and the 1/2" fresh water hose, which can be found at a good auto parts or hardware store. In my search I stumbled across red and blue 1/2" options from a local hose supplier; they are rated for the appropriate temps, safe for use with potable water, and the red and blue color coding are welcome additions as they make for a tidy install. We will likely start adding the red/blue hose to our Helton kit offerings, or at least offer the hose by the foot for shower customers. The coolant hoses are a little more application-specific and more than that they are really specific to where/how you mount your exchanger. Because I wasn't 100% sure how everything was going to lay out under the hood with the dual batteries, compressor, auxiliary fuse block, etc., I opted to make the coolant hose components an on-the-fly parts need, easy enough to source during our build at the local auto parts stores.

Helton Hot Shower Kit

Batteries are seemingly as emotional a choice as tires, well almost. Browse internet forums and you'll find opinions based in every direction, and while I think there is much to be gained from the opinions of others, in some cases the momentum of love or hate can overwhelm the reality. I've been using Optima batteries in my FJ40 for nearly 12 years, never had one fail, never even had one go dead without good cause, they have just worked and worked. About 5 years ago I decided to replace them before a big trip just as a preventive measure, and the old one is now in my forklift, where it works fine as long as nobody leaves the key on

Battery Cable Parts Drawer @ Cruiser Outfitters

I placed a last minute order with Paul at PFran LED's Lighting for his 100 Series LED light kit. Paul was out for a few days (his wife was in the hospital) but he was quick to respond and in just a few days I had his well-assembled kit ready for the install. The kit replaces all of the standard interior bulbs with high-power LED inserts and also includes a few spares just in case you have a failure down the road. I was excited to shed some light on the interior (pun intended).

PFran LED kit tailored for the 100 Series Land Cruiser (Photo Courtesy of pfranleds.com)

Josh Vanderford from Ajik Overland Exchangehelped us out with the new to the market Landtank modified fan clutch. The fan clutch starts as an brand new OEM fan clutch and is specially modified using a high quality 15,000 centistoke oil. This thicker oil ensures lower engine temperatures, vital for keeping the 2UZ-FE cool with the additional loads and type of uses this rig will see. Additionally, the modified fan clutch offers better air conditioner performance but pulling more air through the AC condenser. I'd advise anyone building a 'heavy hundy' to consider the upgrade, just a phone call away.

Landtank modified 100 Series fan clutch from Ajik Overland

Last but not least was to make sure I had all of the various electrical components ready to go. Besides generic wiring supplies such as bulk wire, relays, heat-shrink, etc., I would also need a fuse block, 12V outlets, USB outlets, and a fridge outlet for the back. I opted for my standard choices: a Blue Sea Fuse block assembly, Waytek Wire & RaElCo for my wire, connector and heat shrink needs, and Will at Sierra Expeditions hooked me up with a couple of the new-to-the-market Blue Sea USB outlets that he had just got in stock.

Wiring Parts Drawer @ Cruiser Outfitters

Where can you buy all (most

Now onto the planning, this is where I really geek out. I worked to develop a list of nearly 200 tasks that would need to be completed during the build, some dependent on other items, and some have dependents waiting on completion. With the list developed I was able to build a Gantt chart which visually dictated the order of operation that would need to happen for all of the components to make their way on the vehicle. While this might be a little over the top for some, I think it's a wise way to prioritize your limited spare time whether you plan to knock out the build in a short time period (like a weekend

The weekend agenda, already knocked off a few items by the time a photo was snapped

With the Gantt chart refined and finalized, I tuned the project down to ~50 major project task headings and transferred them to the dry erase board in the shop.

Next Up: The Build

cruiseroutfit

Well-known member

Hey Kurt, great to meet you today! Always fun to meet cruiser heads. Loved your collection, and ill keep trying to get my wife into a hundy

Sent from my iPad using Tapatalk HD

Right on, glad to put a name to a face to a username, had no clue that was you, I've followed your 80 budget build. Sorry I didn't have more time to chat, crazy day in the shop as my two guys were out this morning. Let me know if I can help out with anything on your build!

cruiseroutfit

Well-known member

Very inspiring thread. Thanks for posting the LED lights kit. Would love to see before/after photos when it's installed.

For sure, I know I snapped a couple of side by side photos of 2nd row individuals and the door lights. The difference is quite amazing. My wife wouldn't notice if I did a diesel conversion or cut the top of the 100, but she noticed the difference of interior lights immediately

jim65wagon

Well-known member

I love the pic of all the parts laid out just as they go on the LC.......and I dig the old school truck!Death Star Build Part# 3: Parts Acquisition & Install/Build Planning

The collection of build parts lined up & ready for install

All mounted & balanced @ Big-O, Ready for the install

cruiseroutfit

Well-known member

pfran has excellent products!

He does, I need to get his kit installed in my Tacoma. You don't notice how weak the stock bulbs are until you've been privy to the others

cruiseroutfit

Well-known member

I love the pic of all the parts laid out just as they go on the LC.......and I dig the old school truck!

Thank and thanks. The build layout pic was fun for us to setup, please it really gave us a chance to start from the front and work our way to the back with all of the parts, making sure everything was there. The FJ45 is a 1966, it 'technically' belongs to my wife

2025 deleted member

Well-known member

Nice 45!

cruiseroutfit

Well-known member

Nice 45!

Thanks! Its been a fun truck. It is a long-term build project, so far we've worked to get it back to stock, then I'll work to clean up the body/paint.

cruiseroutfit

Well-known member

Sweet thread...I noticed you had a Suction Cup/Holder for your Helton Shower. I don't remember mine coming with one...Can I buy one?

Thanks man!!!!

Nope, you can have one

There should have been one in your gray shower bag but it might have been left out? No biggy, I have a pile of them here. Its nice to attach it to your side window or fender. Swing by and its all yours.

Similar threads

- Replies

- 0

- Views

- 961

- Replies

- 0

- Views

- 417

- Replies

- 1

- Views

- 1K