Wh1t3nukle

I gotz dis

I can't but wonder if black pipe was being used, like 1.5" ID Sch 40.

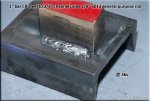

Come back with a picture of it supported on the slider! We want to see that pinch self-clear.

Come back with a picture of it supported on the slider! We want to see that pinch self-clear.